Blind plug fluid connector with spring not exposed on a flow channel

A connector and flow channel technology, applied in the field of blind plug fluid connectors, can solve the problems of complex design and processing, relatively high requirements for spring materials, etc., and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

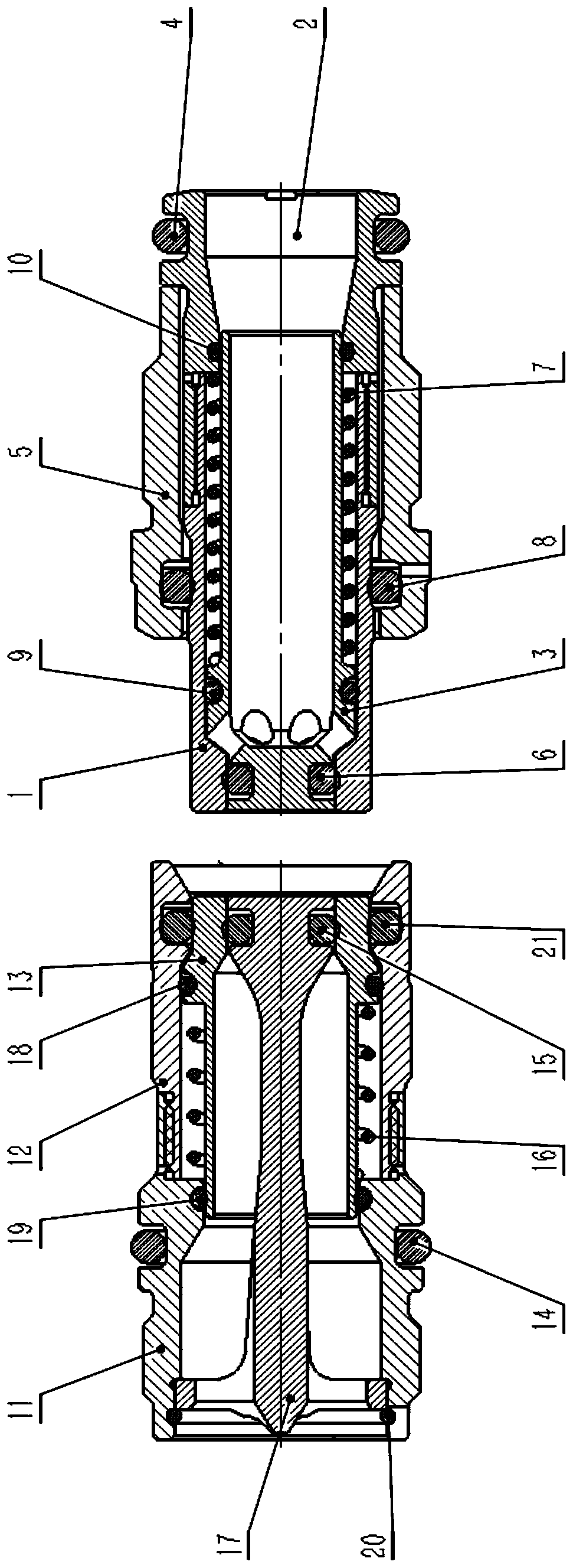

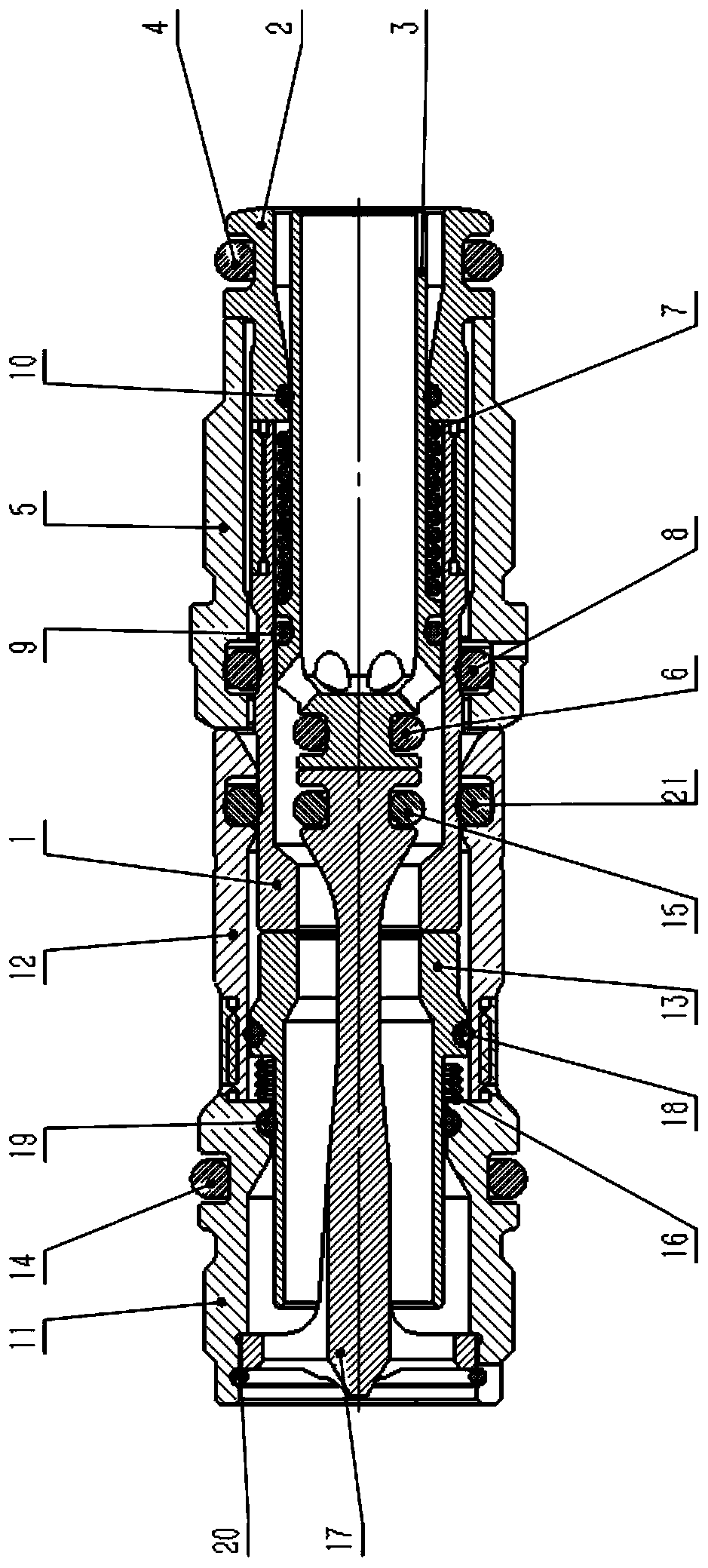

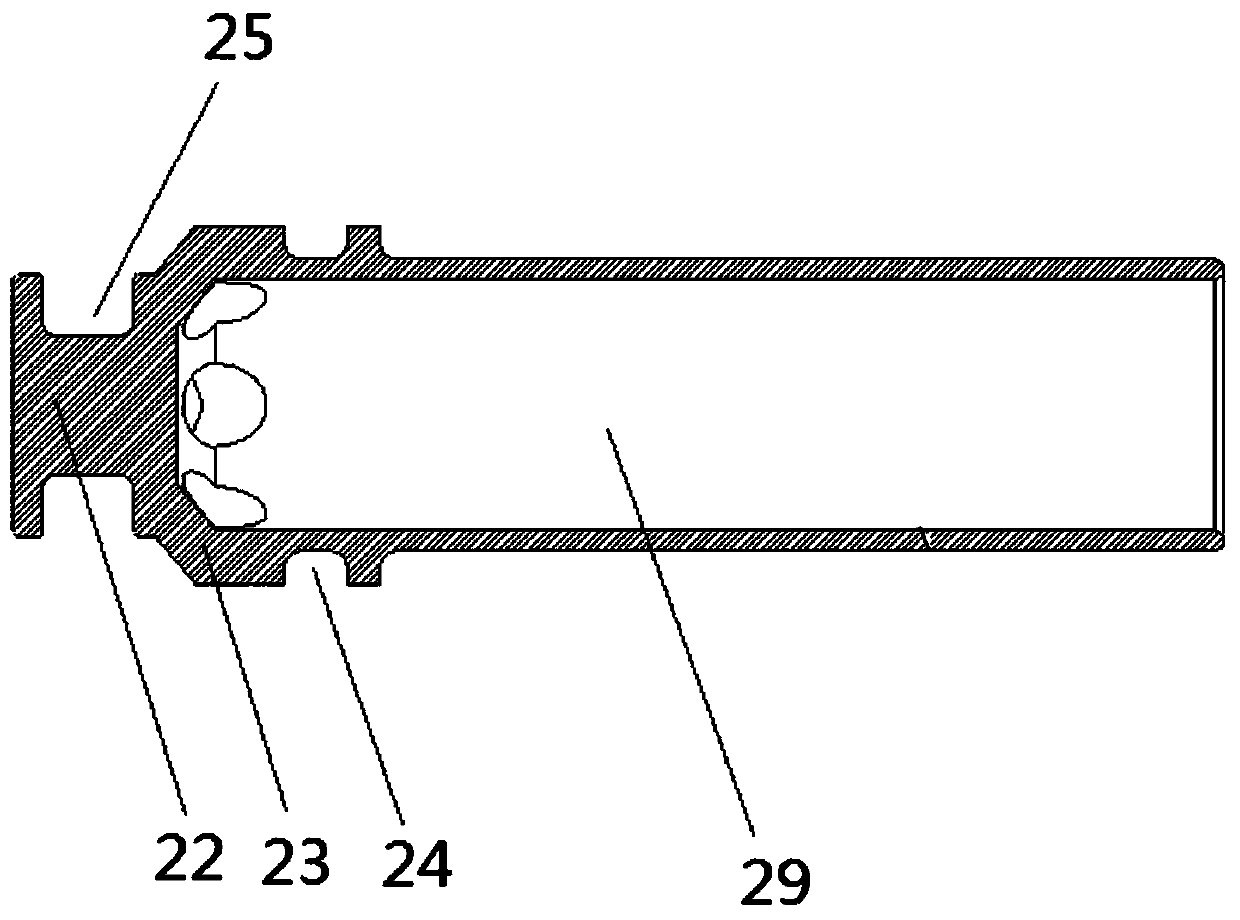

[0027] Such as Figure 1 to Figure 5 As shown, the present invention is a blind plug fluid connector whose spring is not exposed to the flow channel, including a male end connector and a female end connector, and the male end connector includes a first male main shaft sleeve 1 and a second male end The main shaft sleeve 2, the first male end main shaft sleeve 1 and the second male end main shaft sleeve 2 are connected through threads, and the first male end main shaft sleeve 1 is provided with a first passage 26 and a second passage 27, the first passage 26 and the second main shaft sleeve 2 The second channel 27 communicates, the diameter of the first channel 26 is smaller than the second channel 27, and the connection between the first channel 26 and the second channel 27 is a tapered surface; the second male end main shaft sleeve 2 is provided with a third channel 30 , the third channel 30 communicates with the second channel 27 , the third channel 30 is a bell mouth struct...

Embodiment 2

[0035] Such as Figure 1 to Figure 5 As shown, on the basis of Embodiment 1, the second male end main shaft sleeve 2 is also provided with a first vent hole, and the first air vent hole communicates with the male end spring 7, and the first female end main shaft sleeve 11 There are also several second air holes on the top, and the second air holes communicate with the female end spring 16. The first air hole and the second air hole provided can ensure that the female end spring 16 and the male end spring 7 can be kept in contact with the external air pressure. Connected state, so as to ensure the normal compression and rebound of the spring.

[0036] The second male end main shaft sleeve 2 is also provided with an eighth groove, and a first sealing ring 4 is also arranged in the eighth groove; the male end connector is also provided with a mounting nut 5, the The mounting nut 5 is connected to the first male end main shaft sleeve 1 and the second male end main shaft sleeve 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com