A device for measuring spring stiffness coefficient

A technology of stiffness coefficient and spring structure, applied in the field of teaching equipment, can solve the problems of lack of shielding and anti-falling function, complicated operation, inconvenient to carry, etc., and achieve the effect of increasing convenience, increasing comfort, and facilitating search.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

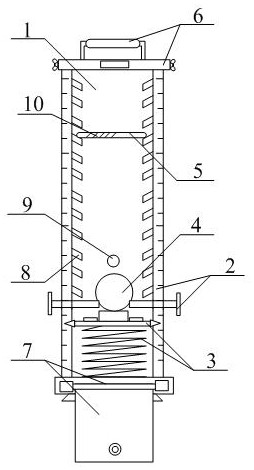

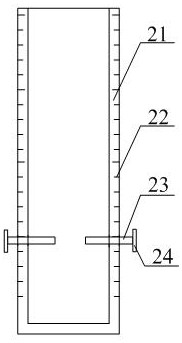

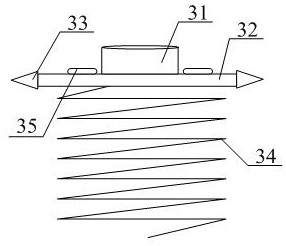

[0037] as attachedfigure 1 to attach figure 2 As shown, the present invention provides a device for measuring the spring stiffness coefficient, including a protective support shell 1, a limit support frame structure 2 with scale lines, a stiffness coefficient measuring spring structure 3, a test ball 4, and a plastic indicator plate 5 , which can be marked with a protective cover structure 6 for easy carrying, a foldable protective support base structure 7, an anti-drop stopper 8, a card hole 9 and a fluorescent sticker 10, and the limit support frame structure 2 with scale lines is fixed On the front surface of the protective support shell 1; the protective support shell 1 is installed on the inner upper side of the foldable protective support base structure 7; the stiffness coefficient measuring spring structure 3 is installed inside the protective support shell 1 The lower side position; the test ball 4 is arranged in the upper middle position of the limit support frame st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com