Process data monitoring method and process data monitoring system

A process data and monitoring system technology, applied in registration/instruction quality control systems, manufacturing computing systems, data processing applications, etc., can solve problems such as difficult interaction and one-sided data monitoring methods, and achieve the effect of improving interception efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

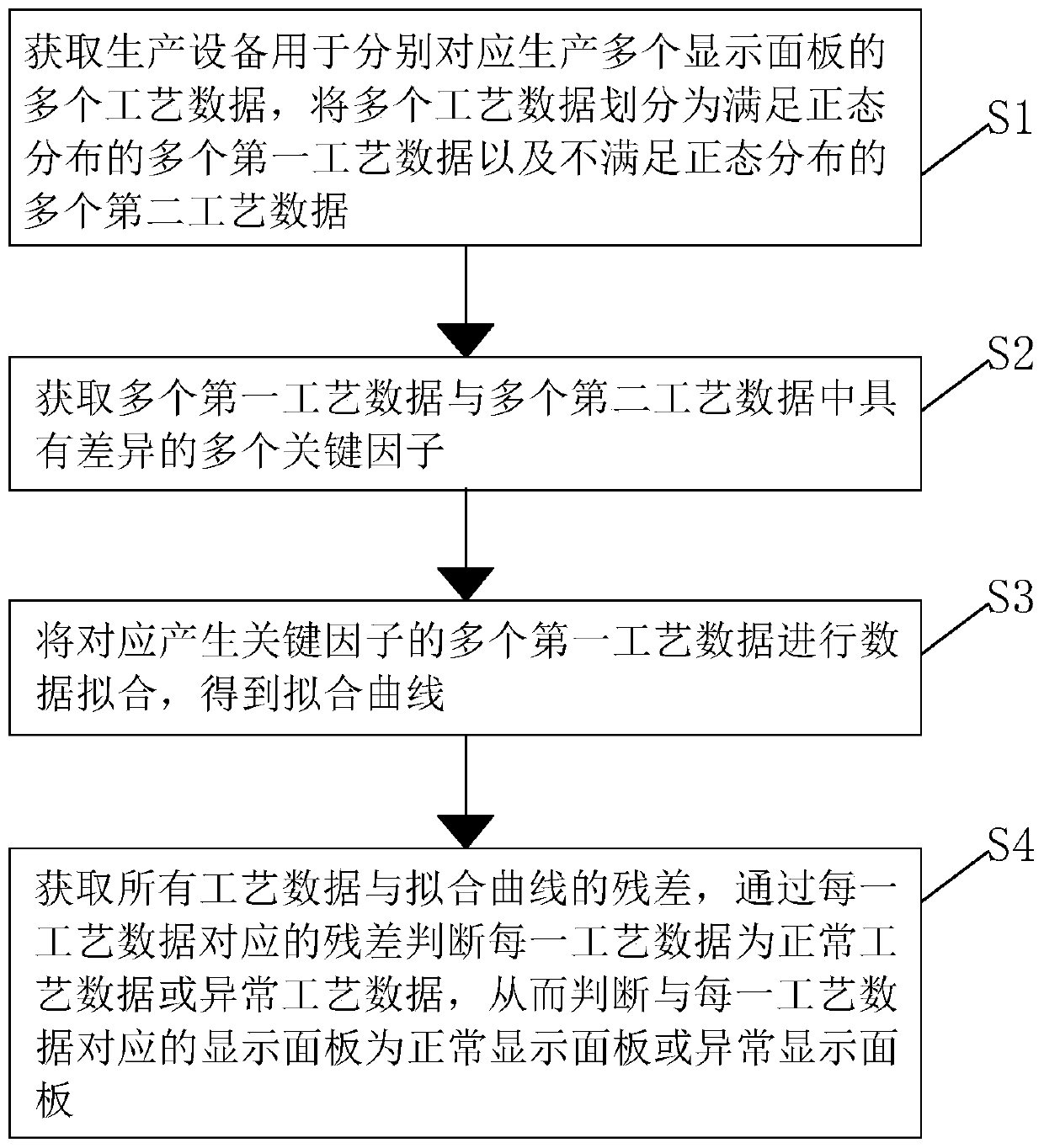

[0031] see figure 1 , the invention provides a process data monitoring method, comprising the steps of:

[0032] Step S1. Obtain multiple process data of the production equipment corresponding to the production of multiple display panels, and divide the multiple process data into multiple first process data that satisfy the normal distribution and multiple second process data that do not satisfy the normal distribution. process data;

[0033] Step S2, acquiring a plurality of key factors having differences between the plurality of first process data and the plurality of second process data;

[0034] Step S3, performing data fitting on a plurality of first process data corresponding to key factors to obtain a fitting curve;

[0035] Step S4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com