A high power density magnetic compression power generation mechanism and a generator including the same

A technology of high power density and magnetic compression, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of insufficient power density of power generation units, limitation of power generation efficiency ratio, large volume of power generation devices, etc., to improve space utilization and perfect magnetic circuit , Improve the effect of induced electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

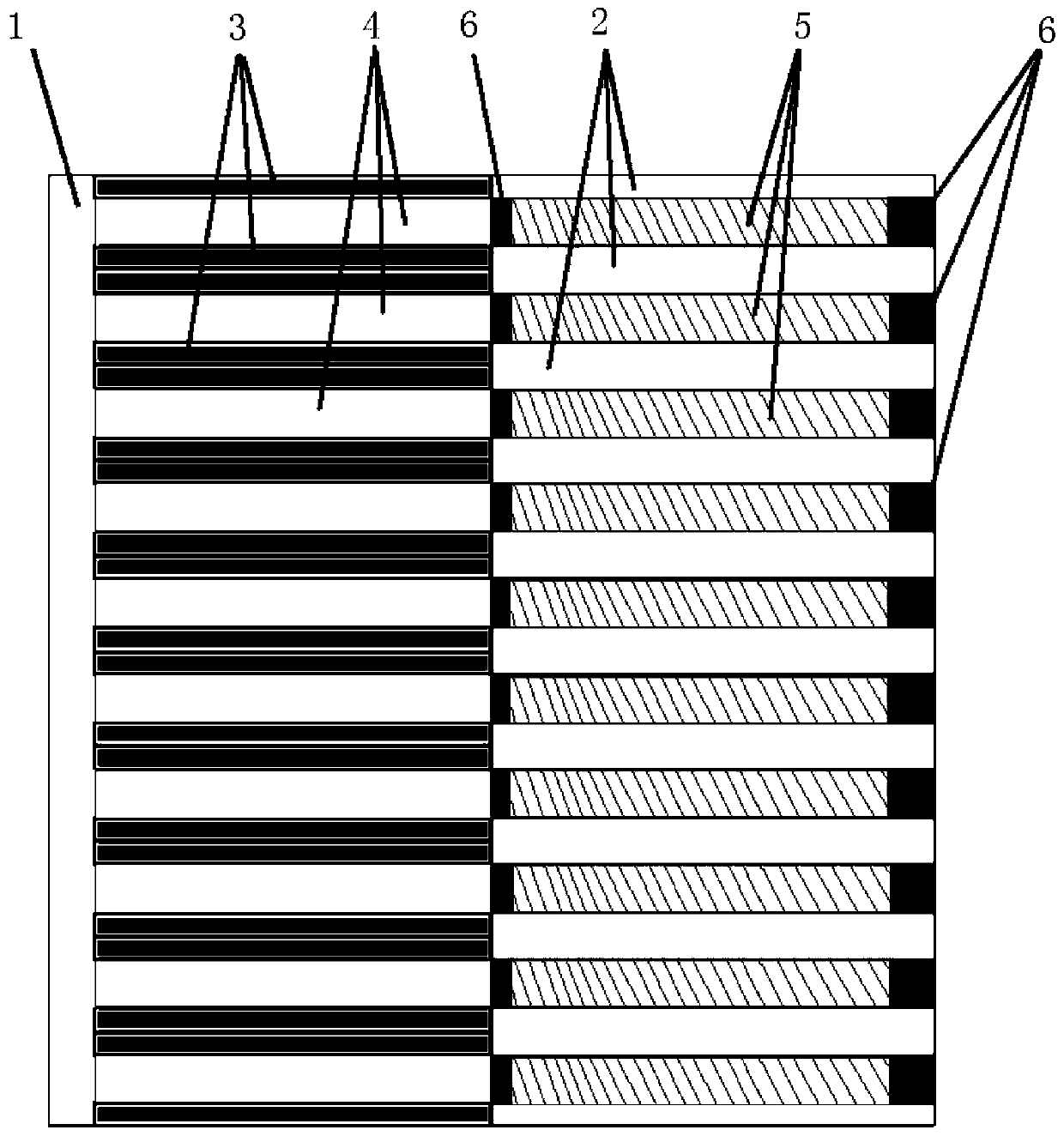

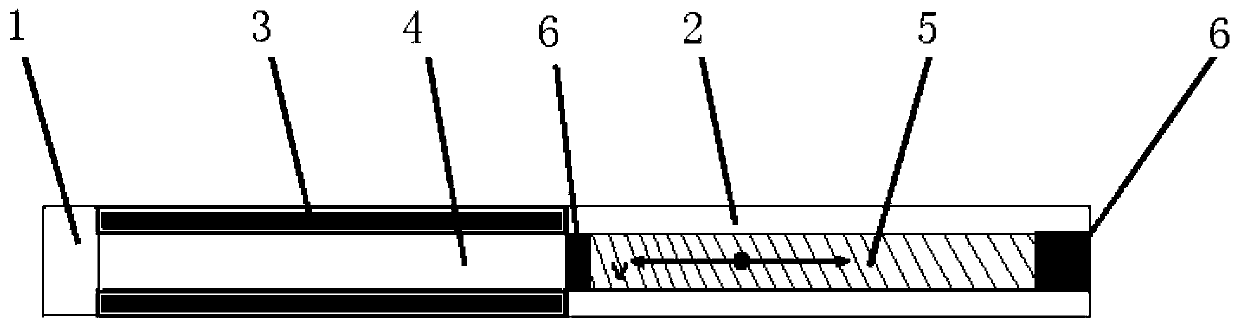

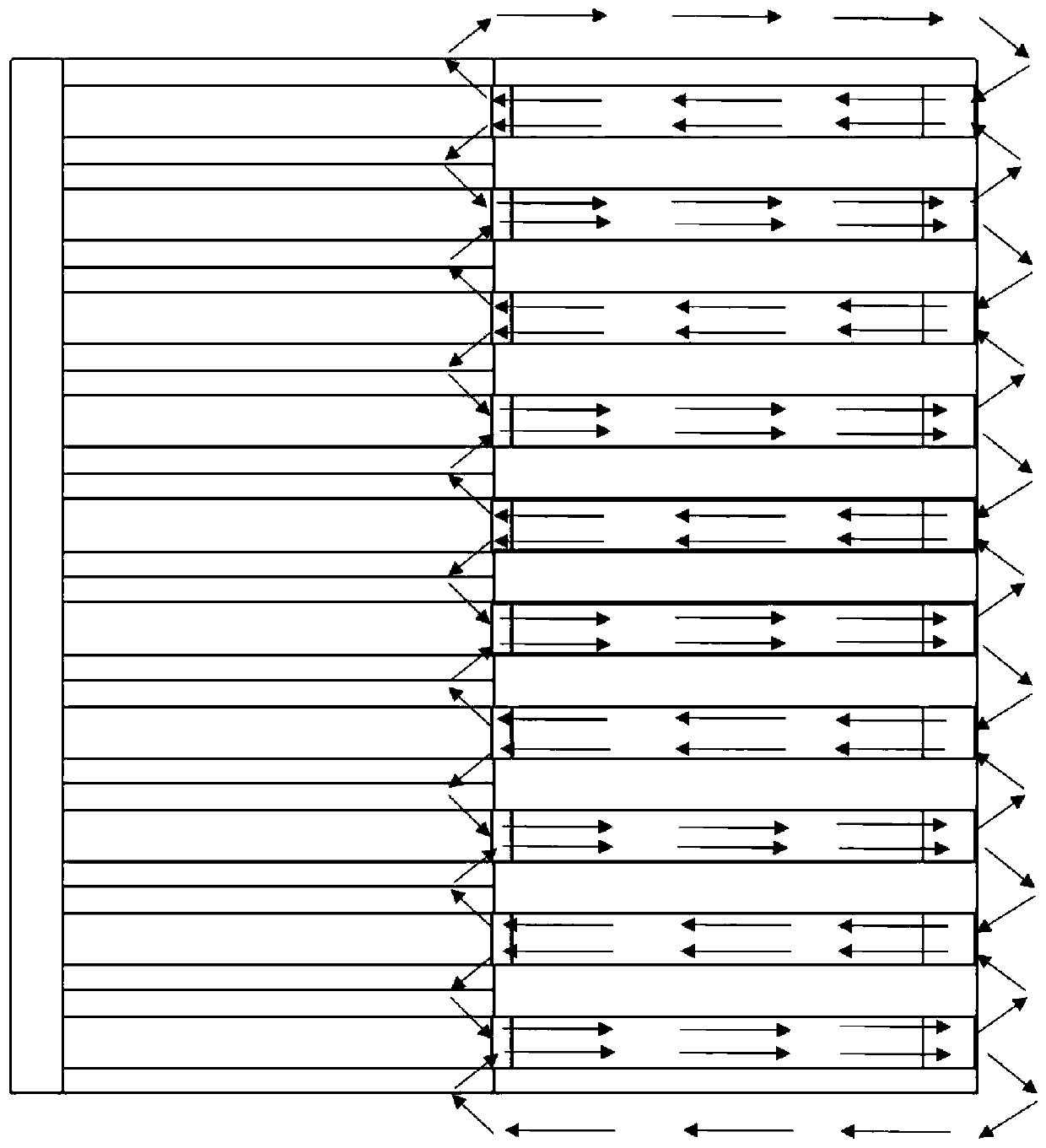

[0028] Refer to as figure 1 with 2 As shown, the high power density magnetic compression power generation mechanism of this embodiment includes: a stator part and a mover part that can move relatively.

[0029] The stator part includes a strip-shaped first stator core 1, and a plurality of second stator cores 2 which are independently arranged from the first stator core 1 and are perpendicular to the first stator core 1. The second stator cores 2 are distributed and arranged in parallel, that is, there is a gap between two adjacent second stator cores 2 . Moreover, a group of boneless coils 3 is arranged between the end of each second stator core 2 and the first stator core 1, and the gaps between the plurality of second stator cores 2 are respectively the same as those of the plurality of second stator cores 2. The gaps between the boneless coils 3 communicate to form a plurality of parallel linear motion spaces 4 .

[0030] Specifically, the first stator core 1 , the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com