Ultrasonic cleaning device for quartz sand

A cleaning device, ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, solid separation, etc., can solve the problems of vibrating screening machines that cannot work, are not applicable, and have a long production process, so as to improve the processing environment and clean The effect of high degree and reduced sedimentation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

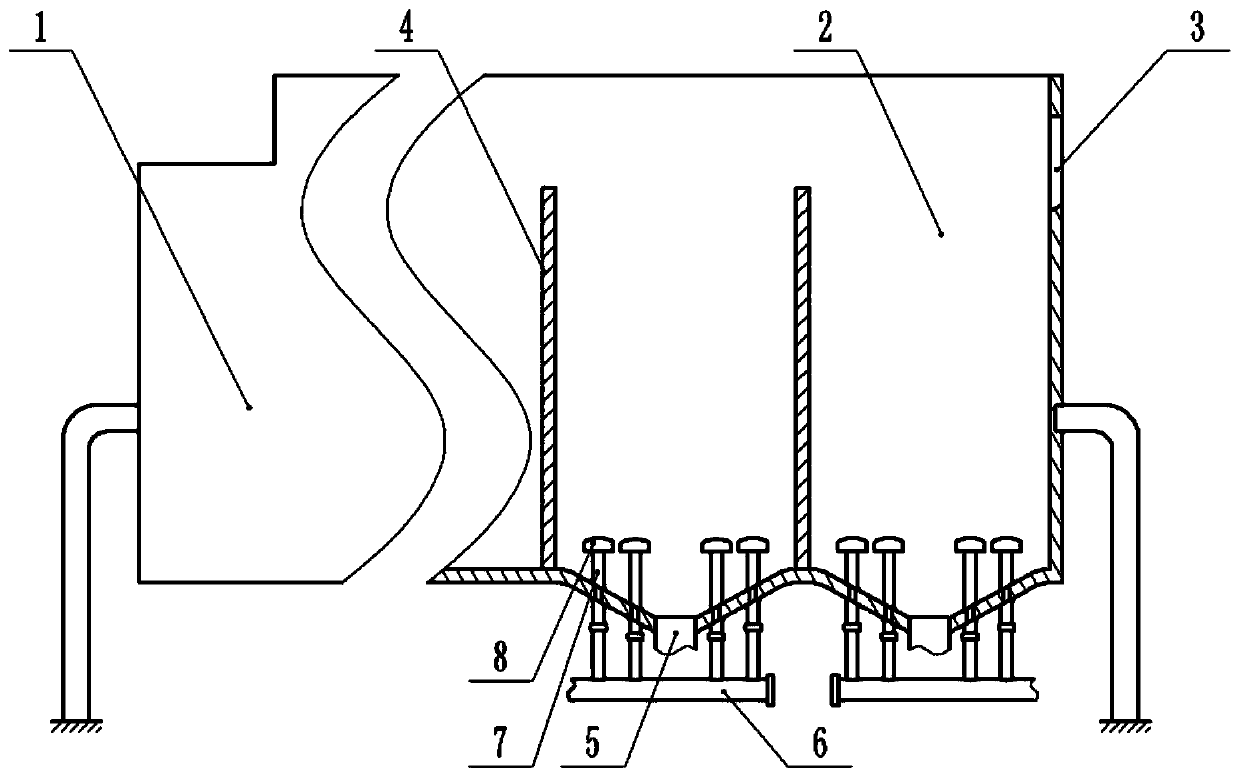

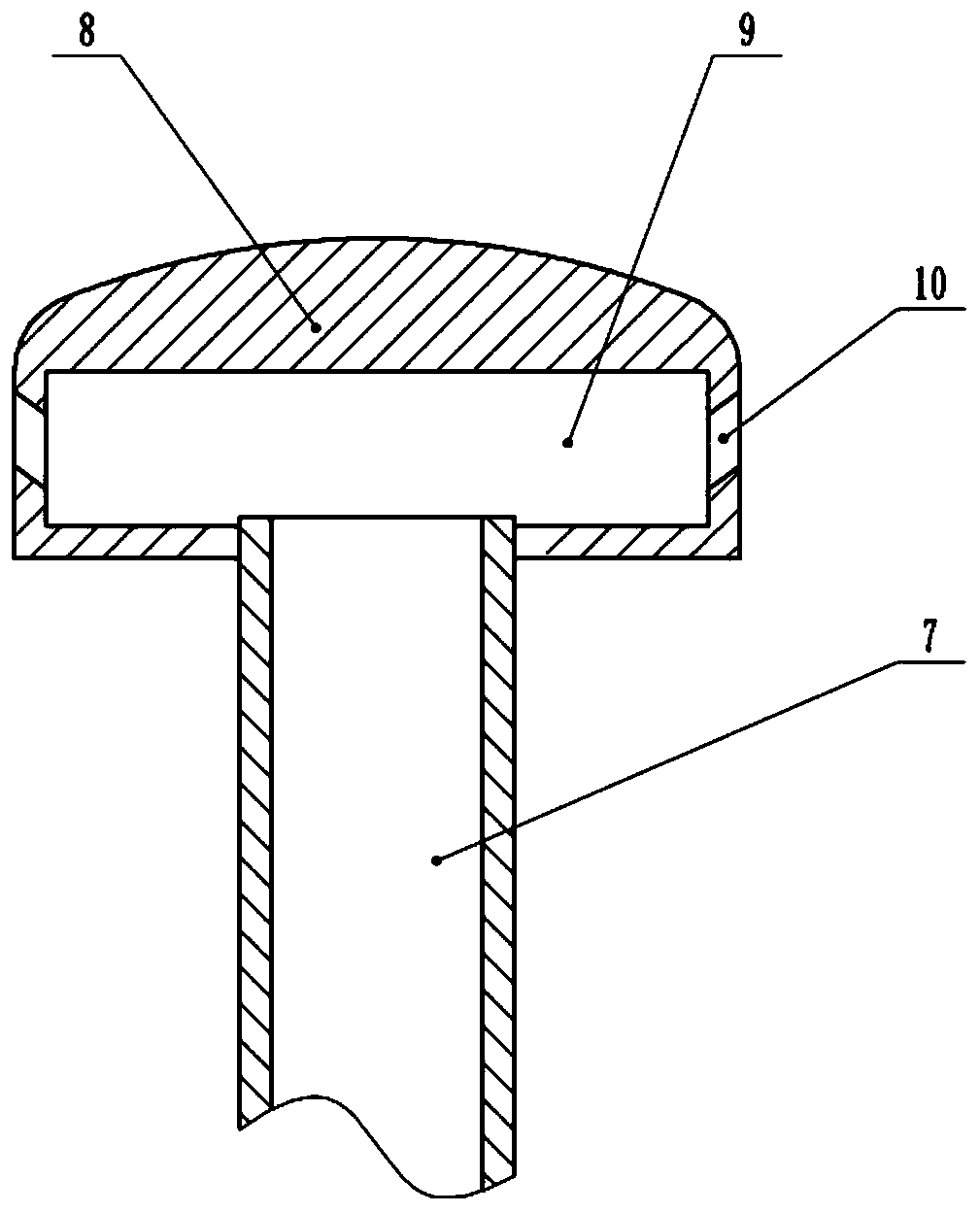

[0038] Such as figure 1 As shown, an ultrasonic cleaning device for quartz sand includes a cleaning box 1, the right side of the cleaning box 1 is provided with a sand inlet 3 for the mixture of sand and water to enter, and the left side of the cleaning box 1 is provided with a sand outlet for water supply and discharge. A plurality of partitions 4 are parallelly arranged in the cleaning box 1 along the length direction, and the heights of the partitions 4 are all lower than the height of the side walls of the cleaning box 1 . A plurality of partitions 4 divide the cleaning box 1 into a plurality of cleaning chambers 2. The cleaning chambers 2 are all in the shape of a cuboid. The center of the bottom of the cleaning chamber 2 is provided with an openable and closable sand discharge port 5. Specifically, the bottom of the cleaning chamber 1 A bottom plate that can block the sand discharge port 5 is slidably connected, and the bottom of the cleaning chamber 2 is provided with a...

Embodiment 2

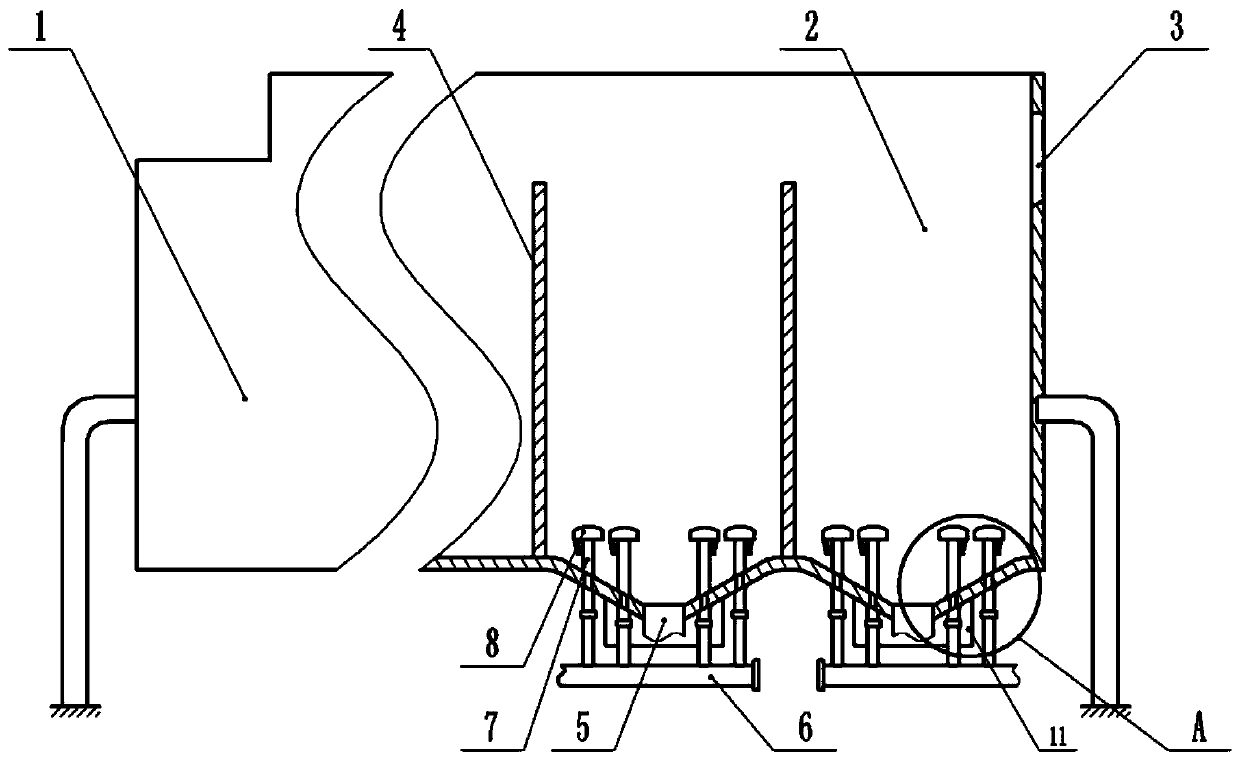

[0048] The difference between this embodiment and Embodiment 1 is that the settings of the ultrasonic generator 11 are different, specifically, in combination with image 3 As shown, the number of ultrasonic generators 11 is 1 / 2 of the number of cleaning chambers 2, and the bottoms of half of the cleaning chambers 2 near the sand inlet 3 sides are correspondingly equipped with ultrasonic generators 11, and the ultrasonic generators 11 The frequency is 33khz. During the implementation process, the ultrasonic generator 11 is started intermittently, and the time interval between each start is 2-4s, and along the flow direction of the sand-water mixture, the start-up time interval of the ultrasonic generator 11 is gradually increased.

[0049] Compared with Embodiment 1, in this embodiment, the frequency of the ultrasonic generators 11 is kept consistent, the number of ultrasonic generators 11 is reduced and the ultrasonic generators 11 are started intermittently, which can save e...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that the setting of the water supply mechanism is different, specifically, in combination with Figure 5 As shown, the water supply mechanism is arranged on the front and rear side walls of the cleaning chamber 2, and the water supply mechanism includes a plurality of water spray holes 10 provided on the front and rear side walls of the cleaning chamber 2, and the water spray holes on the side walls of each cleaning chamber 2 10 are provided with multiple rows and columns, distributed in a matrix, the end of the water spray hole 10 close to the cleaning chamber 2 is inclined upward, the side wall of the cleaning box 1 is slidably connected with a baffle 13, and the baffle 13 can block at least one row or a row Spray hole 10. In this embodiment, three rows and four rows of water spray holes 10 are arranged on the side wall of the cleaning chamber 2, and the baffle 13 is arranged horizontally, and the baffle 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com