Six-shaft profiling cutting machine adjustable in cutting depth

A technology of cutting depth and cutting machine, applied in the direction of copying process control system, metal processing equipment, manufacturing tools, etc., can solve the problems of only cutting through, unable to control the thickness, and profiling substrate equipment can not be realized, so as to achieve flexible adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

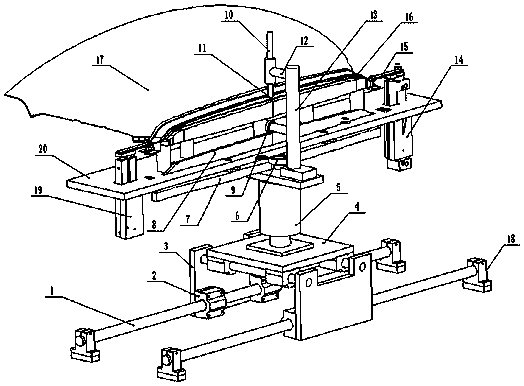

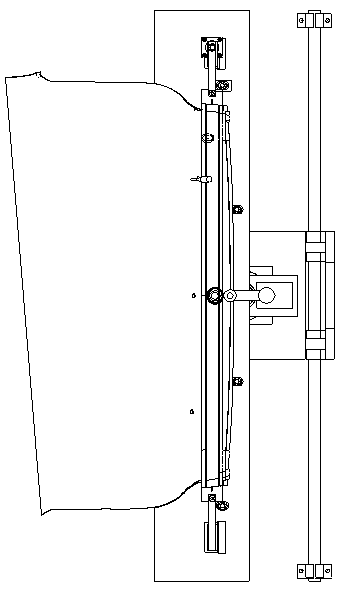

[0018] A six-axis adjustable cutting depth profiling cutting machine, including a bracket, a base, a cutting tool, a workbench and a membrane base, the workbench is set on the bracket, the cutting tool is set on the base, and the The base includes a smooth shaft 1 (that is, a shaft with a smooth surface), a shaft sleeve 2, a fixed plate 3 and a bottom plate 4. The shaft sleeve 2 is sleeved on the smooth shaft 1, and the shaft sleeve 2 can move along the smooth shaft 1. The fixed plate 3 is fixedly arranged on the shaft sleeve 2, the base plate 4 is arranged on the fixed plate 3 through a smooth shaft, and the bottom plate 4 can move along the smooth shaft, and the smooth shaft 1 is arranged on the support 18, see According to the accompanying drawings, the smooth shaft 1 is fixed on the ground through the support 18. There are four shaft sleeves 2, and every two shaft sleeves 2 are placed on a smooth shaft 1. There are 2 fixed plates 3, each A fixed plate 3 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com