Monocular recognition cotton top-cutting machine

A technology of topping machine and cotton, applied in agricultural machinery and implements, image data processing, cutting tools, etc., can solve the problems of low precision, unsuitability, no direction sensing, etc., and achieve short longitudinal cutting length and low power consumption. , the effect of strong implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

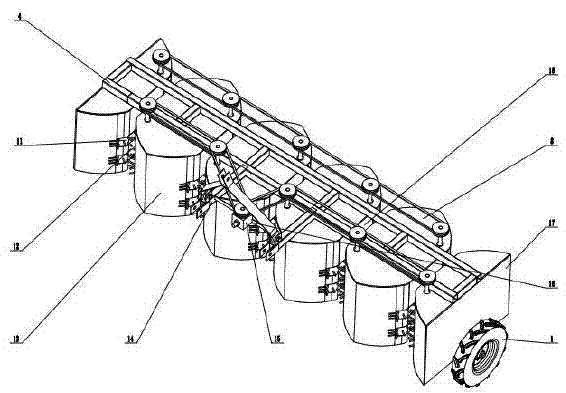

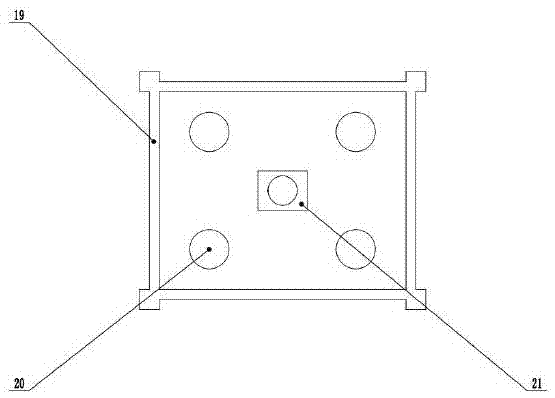

[0022] Embodiment 1: with reference to attached Figure 1 A monocular recognition type cotton topping machine, comprising a grain-holding device, a topping and lifting device, a traction and support device, an image acquisition and processing device, a power device and a frame, is characterized in that the grain-holding device is located at the lower end of the frame and the machine frame The image acquisition and processing device is set at the inner end of the Fuhe baffle, the topping and lifting device is set at the lower end of the frame plate, which can track the top of the cotton plant, and the traction device is set at the front of the frame and the tractor. Towing device connection.

Embodiment 2

[0024] The difference between this example and Embodiment 1 is that the frame includes a back beam 2, a cross beam 3, a front beam 4 and a frame plate 8, and the above-mentioned back beam 2 and front beam 3 are fixed together with four cross beams 4 to form the whole frame , The frame plate 8 is installed on the rear bottom of the beam 3 for placing other parts.

Embodiment 3

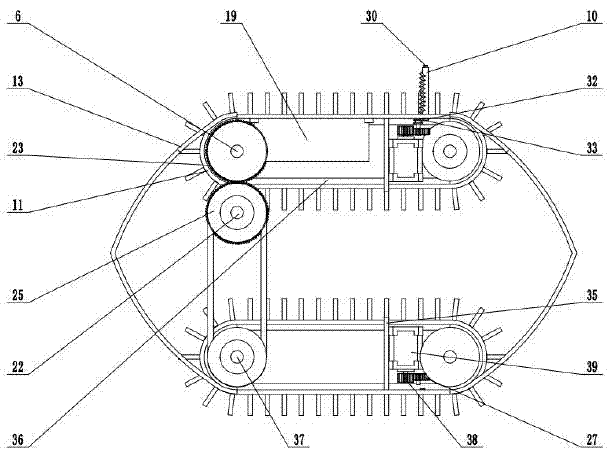

[0026] The difference between this example and Embodiment 1 is that the power unit includes a fixed beam 16, a bevel gear set 15, a pulley transmission set 7, a direction changing driving gear 23 and a driven gear 25 transmission set, and the above-mentioned bevel gear set 15 works It is connected with the power output device of the tractor, the power shaft of the tractor is connected with the bevel gear set 15, and the other end of the bevel gear set is connected with the pulley 7, and the pulley transmits part of the power to some Fuhe monomers through the transmission belt 9, so that the active The pulley shaft 6 rotates, and the remaining part of the power passes through the direction-changing transmission group combined by the driving gear 23 and the driven gear 25, thereby changing the steering, so that the driven pulley shaft 37 rotates in the opposite direction, and provides power for realizing the meshing motion of the Fuhe monomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com