Binocular recognition type cotton top-cutting machine

A technology of binocular recognition and topping machine, which is applied in agricultural machinery and implements, televisions, cutting tools, etc., can solve the problems of low precision, late start of research, and complicated field optical fibers, and achieves short longitudinal cutting length and complete cutting. High rate and long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

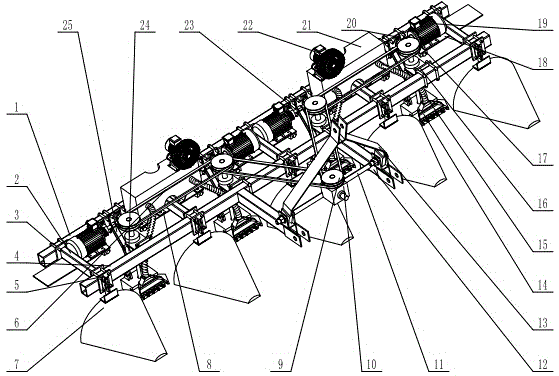

[0025] Embodiment 1: with reference to attached Figure 1 A binocular recognition type cotton topping machine, comprising a power unit, a topping lifting device, a residual bud recovery device, a traction device, an image acquisition and processing device and a frame, is characterized in that the image acquisition and processing device is located at the lower end of the frame motor tray The topping and lifting device is set at the rear end of the frame and connected with the power output shaft of the tractor, which can track and top the cotton. towing device connection.

Embodiment 2

[0027] The difference between this example and Embodiment 1 is that the frame includes a rear suspension beam 1, a crossbeam 2, a U-shaped fixing screw 3, a front suspension beam 4 and a tray 18, and the above-mentioned rear suspension beam 1 and front suspension beam 4 pass through with four crossbeams 2 U-shaped fixed screw rods 3 are fixed together to form the whole frame, and the tray 18 is installed on the rear and lower part of the beam 2 for fixing parts.

Embodiment 3

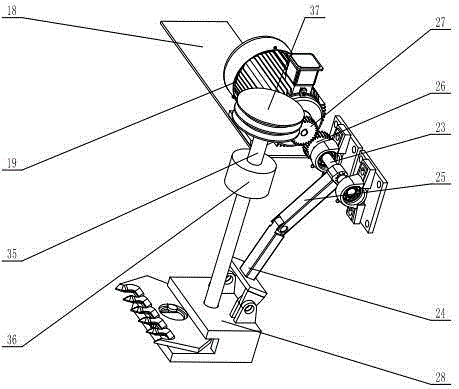

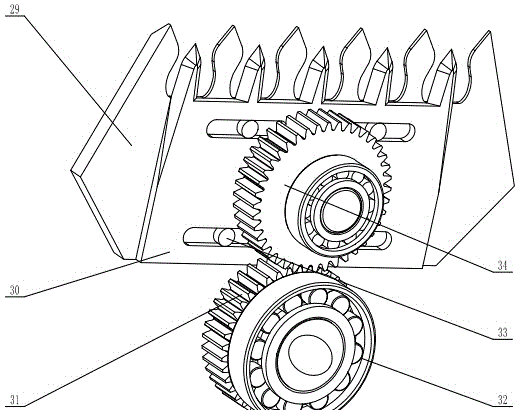

[0029] The difference between this example and Embodiment 1 is that the power set includes a spline transmission shaft 38, a bevel gear set 39, a main transmission shaft 40, a pulley 9 and a transmission belt 6, and the above-mentioned spline transmission shaft 38 works with the tractor power The output device is connected, one end of the main transmission shaft 40 is connected with the bevel gear set 39 through a key, and the other end is connected with the pulley 9 through a key, and the pulley 9 transmits power to the cutting pulley 37 through the transmission belt 6, thereby performing topping Work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com