Finish machining treatment system for gear production and manufacturing

A technology for processing systems and gears, which is applied in the direction of gear tooth manufacturing devices, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to deburr various types of gears, time-consuming and laborious, and prone to burrs on the surface of the gears, etc., to ensure that the Control and ensure the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Exemplary embodiments of the present application are described below with reference to the accompanying drawings. It should be understood that these specific instructions are only used to teach those skilled in the art how to implement the present application, and are not used to exhaust all possible ways of the present application, nor are they used to limit the scope of the present application:

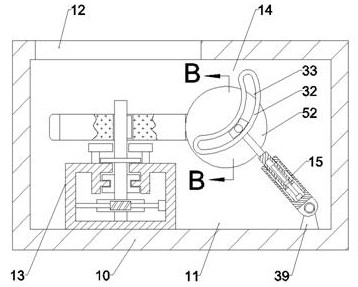

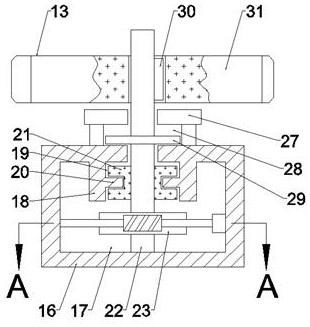

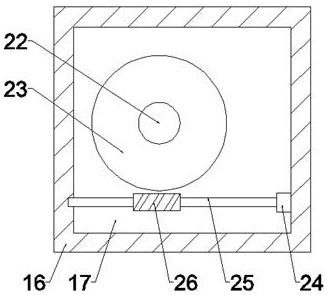

[0016] Such as Figure 1-Figure 5 As shown, a gear production and finishing processing system according to an embodiment of the present invention includes a casing 10, a processing chamber 11 is provided inside the casing 10, and a feeding trough is fixedly provided at the upper end of the processing chamber 11 12. The left end of the lower end wall of the processing chamber 11 is fixed with a cutting mechanism 13, the right end wall of the processing chamber 11 is provided with an adjustment mechanism 15, the upper end of the adjustment mechanism 15 is provided with a transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com