A real-time monitoring device and monitoring method for cement silo materials

A real-time monitoring and cement silo technology, applied to measuring devices, displaying liquid level indicators through pressure measurement, instruments, etc., can solve the problems that operators cannot accurately know the remaining material in the silo, hidden dangers of on-site construction safety, etc. , to achieve the effect of simple and efficient material balance, simplified monitoring of material balance, and sensitive induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

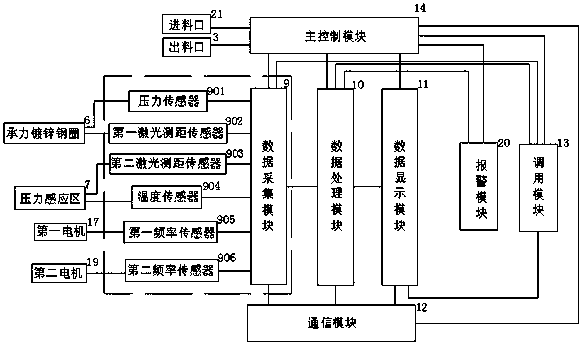

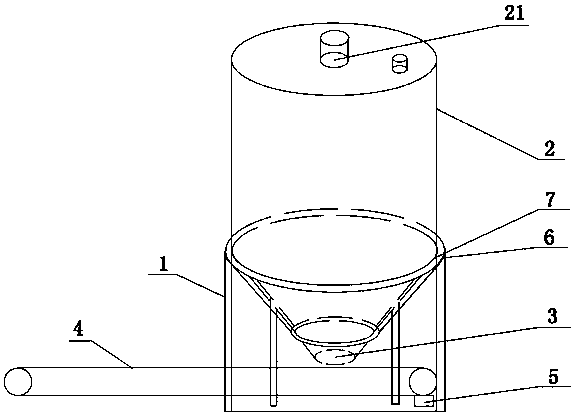

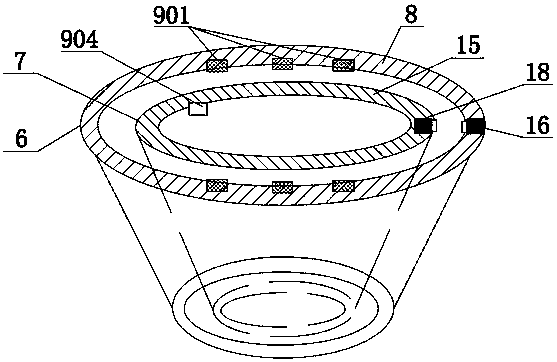

[0038] A cement silo material real-time monitoring device, comprising a cement silo support 1, a cement silo 2 mounted on the cement silo support 1, a material conveyor belt 4 connected to the discharge port 3 at the bottom of the cement silo 2, and connecting and driving the material conveyor belt 4 The third moving motor 5, the cement silo 2 is fixed on the cement silo support 1 with a hanger, and the cement silo support 1 is connected by welding, and also includes a load-bearing galvanized steel ring 6, a pressure sensing area 7, and a pressure sensor 901 And monitoring system, described monitoring system comprises data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com