Method for manufacturing detachable modular tread for concrete casting

A manufacturing method and dismantling technology, which are applied in the directions of construction, building structure, scaffolding accessories, etc., can solve the problems of unfavorable personal carrying, difficulty in passing, difficulty in erection, etc., and achieve convenient transportation and transition, light weight, and avoid direct footing. The effect of stepping on steel bars and pre-buried pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The manufacturing method of the detachable modular pedal for concrete pouring of the present invention comprises the following steps:

[0036] a. Set up a rectangular frame,

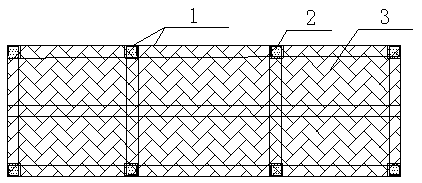

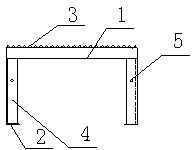

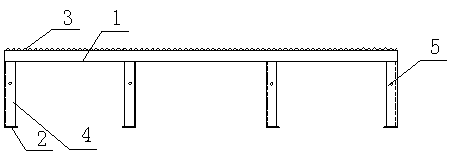

[0037] see now Figure 1-Figure 3 , figure 1 It is a schematic structural diagram of a pedal rectangular frame according to an embodiment of the present invention, figure 2 for figure 1 side view, image 3 for figure 1 main view. As shown in the figure, use the first angle steel 1 to build a rectangular frame with a length of 1800 mm and a width of 600 mm; inside the rectangular frame, the longitudinal rails and cross rails arranged in the shape of "Feng" are welded to form three longitudinal rails and rails with the same distribution spacing. Four crossbars with the same spacing, the distance between two adjacent crossbars is 600mm. The specification of the first angle steel is L50*50*5 angle steel.

[0038] b. Laying grid steel plate

[0039] Lay the grid steel plate 3 on the top surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com