Flow motivating type infinite loop well flushing tool

An infinite circulation and well flushing technology, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc., can solve the problems such as the limitation of the opening times of the circulation valve, and achieve small impact, high reliability and fast response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

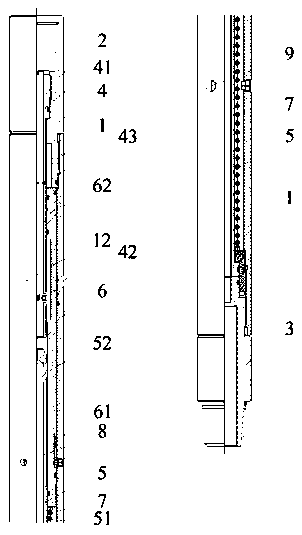

[0034] Such as Figure 1 to Figure 3 As shown, a fluid-inspired infinite circulation well cleaning tool includes a main barrel (1), an upper joint (2) connected to the main barrel (1) through threads, and a lower joint (2) connected to the main barrel (1) through threads. 3), fixed on the upper mandrel (4) of the upper joint (2), fixed on the lower mandrel (5) of the lower joint (3), installed on the piston (6) inside the main cylinder (1), installed on the lower The displacement spring (7) between the mandrel (5) and the piston assembly (5), the displacement element (8) and the limit element (9) fixed on the main cylinder (1), the upper mandrel ( 4) There are through holes (41), upper mandrel bypass holes (42) and pressure holes (43) on the upper side, and blind holes (51) and lower mandrel bypass holes (52) are opened on the lower mandrel , the piston (6) is provided with a transposition slot (61) and the piston bypass hole (62), and the main cylinder (1) is provided with a...

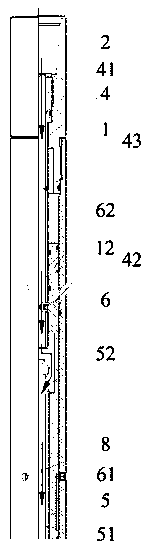

Embodiment 2

[0039] Such as Figure 4 to Figure 6 As shown, a fluid-inspired infinite circulation well cleaning tool includes a main barrel (1), an upper joint (2) connected to the main barrel (1) through threads, and a lower joint (2) connected to the main barrel (1) through threads. 3), fixed on the upper mandrel (4) of the upper joint (2), fixed on the lower mandrel (5) of the lower joint (3), installed on the piston (6) inside the main cylinder (1), installed on the lower The displacement spring (7) between the mandrel (5) and the piston assembly (5), the displacement element (8) and the limit element (9) fixed on the main cylinder (1), the upper mandrel ( 4) There are through holes (41), upper mandrel bypass holes (42) and pressure holes (43) on the upper side, and blind holes (51) and lower mandrel bypass holes (52) are opened on the lower mandrel , the piston (6) is a split piston consisting of an upper piston body (63) and a displacement piston body (64), and the piston bypass hol...

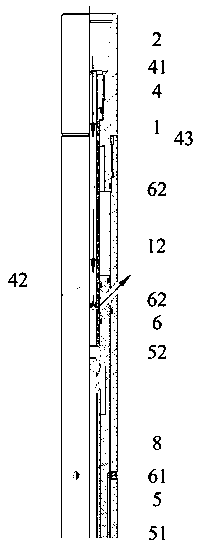

Embodiment 3

[0045] Such as Figure 6 As shown, this embodiment is basically the same as Embodiment 2, the difference is that: the central axis of the piston bypass hole (62) and the central axis of the water hole (12) both intersect the axis of the main cylinder, and the piston bypass hole The angle range between the central axis of the through hole (62) and the central axis of the water hole (12) relative to the axis of the main cylinder is between 20° and 80°.

[0046] Further, the angle between the central axis of the piston bypass hole (62) and the central axis of the water hole (12) relative to the axis of the main barrel is 45°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com