Automatic sample separation robot for food inspection

A robot and grain technology, applied in the field of automatic sample dividing robots for food testing, can solve the problems of low sample distribution uniformity, errors, sedimentation, etc., and achieve the effect of rapid sample dividing work, elimination of errors, and uniform sample distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

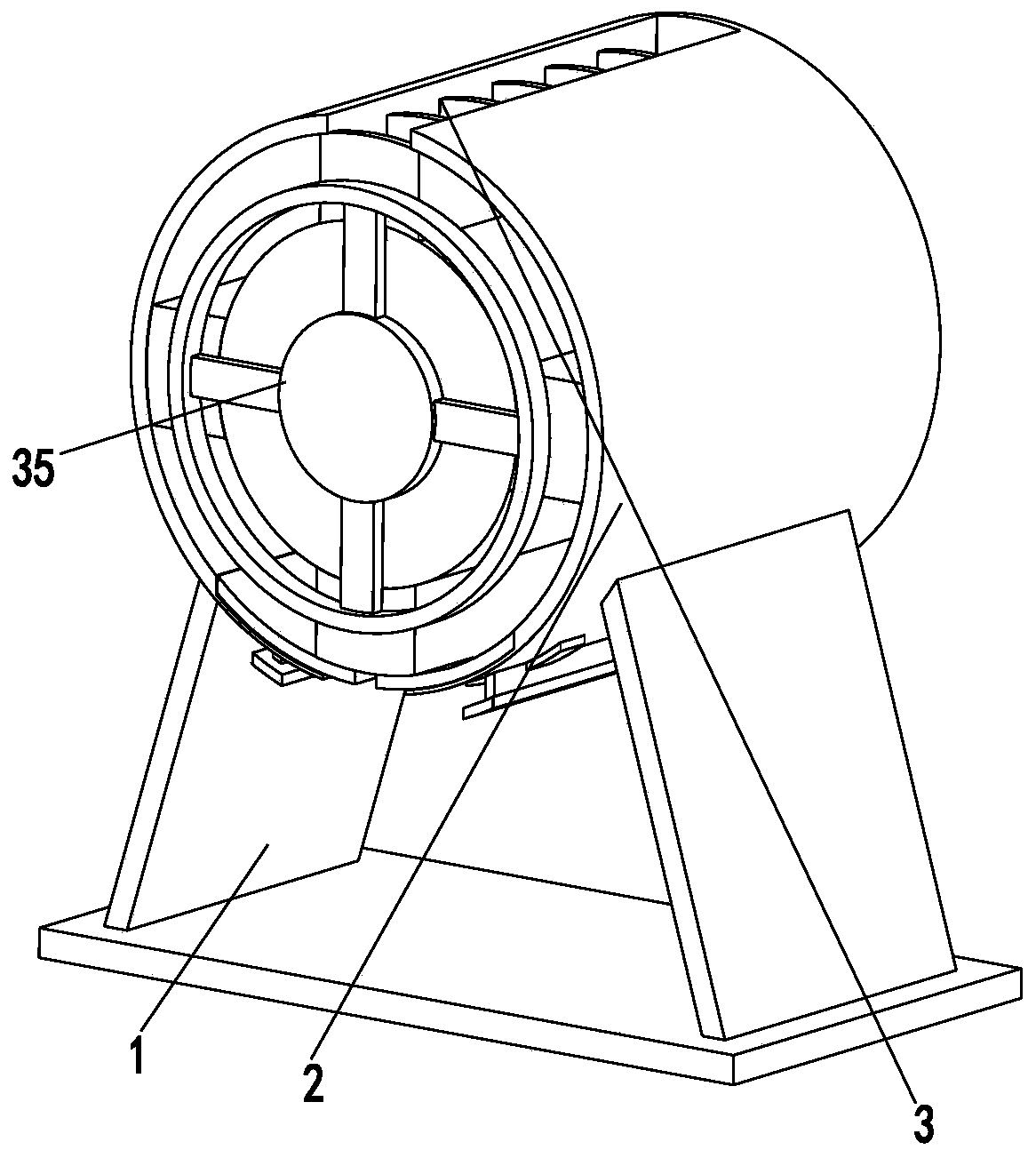

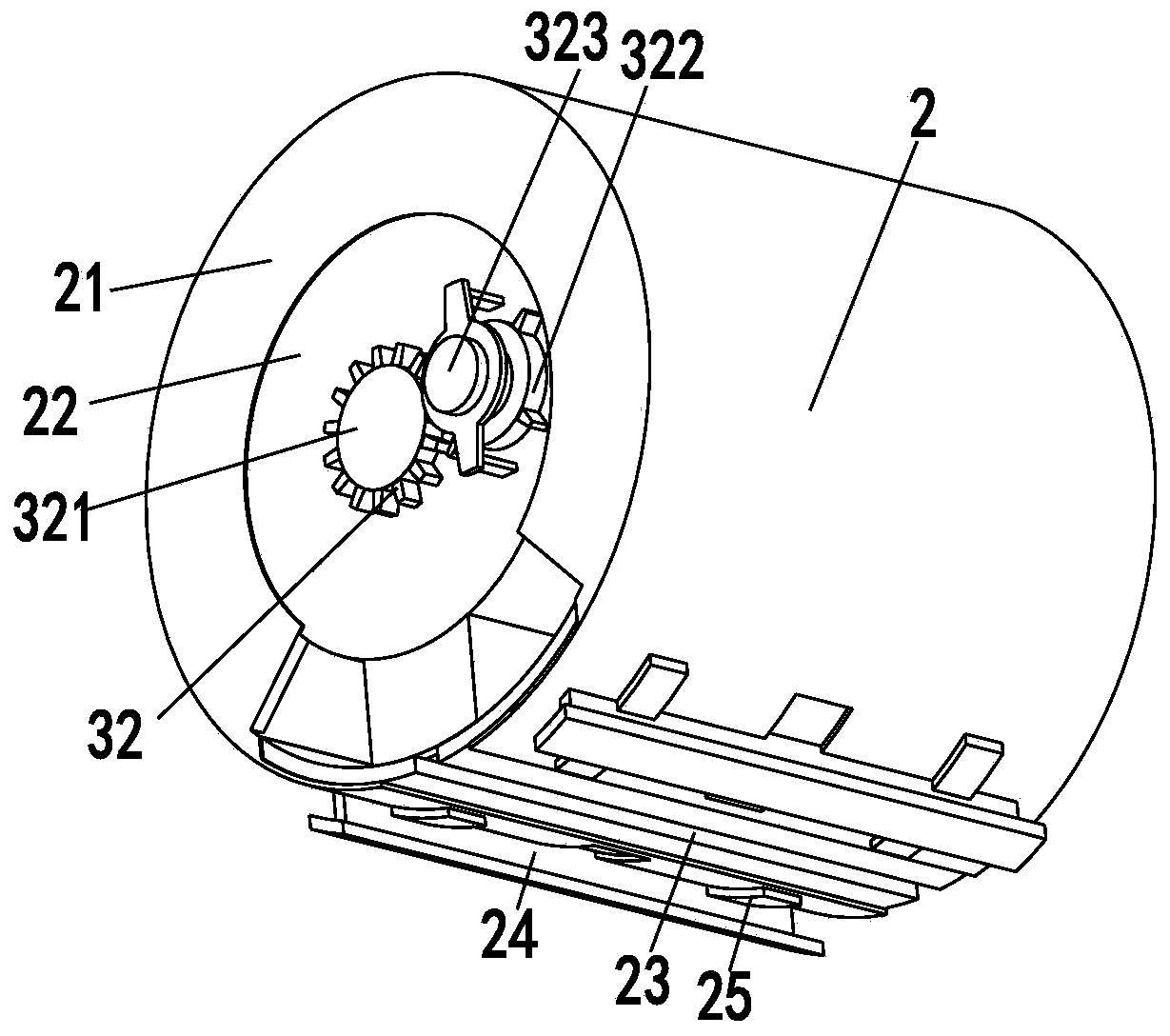

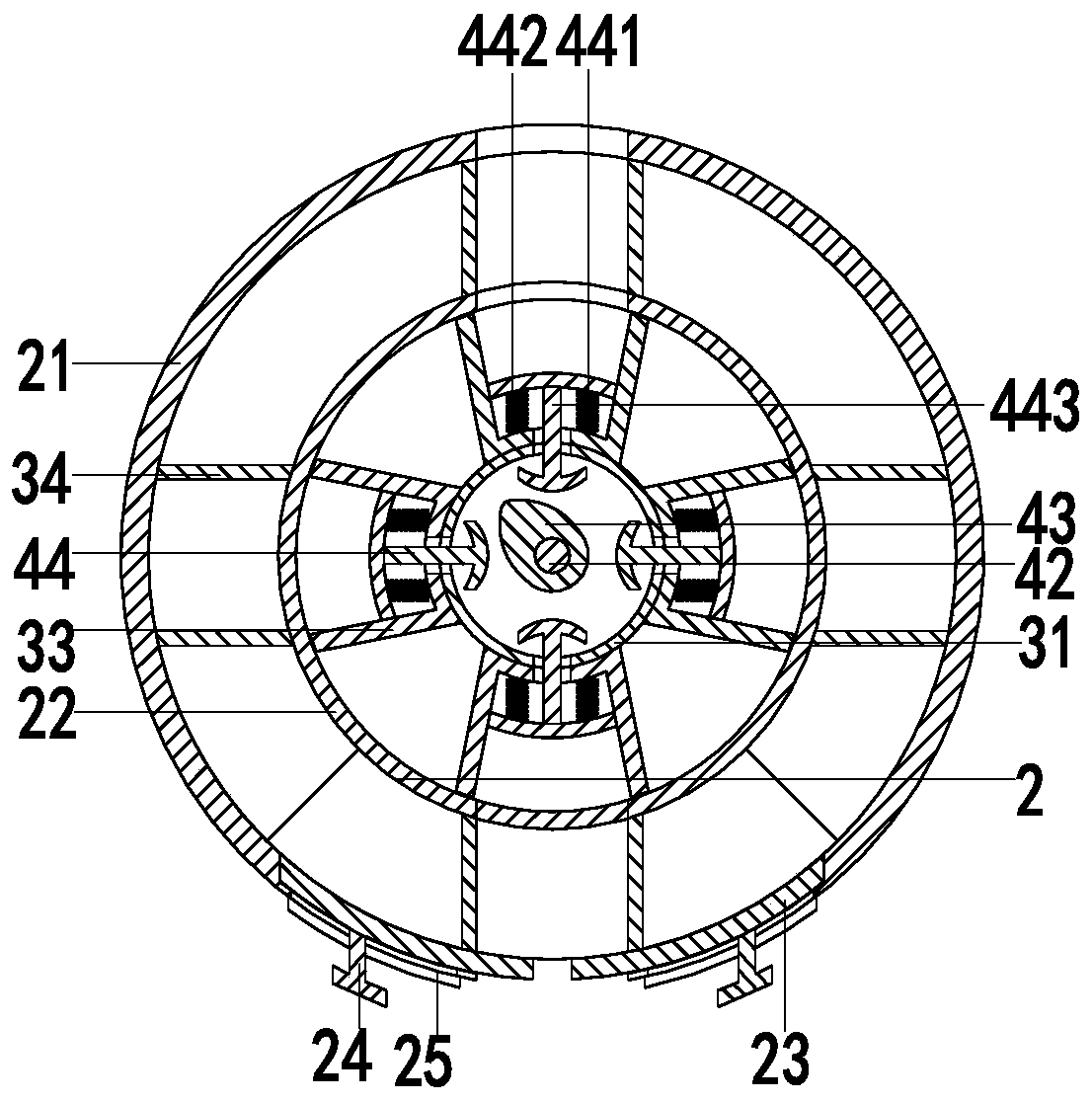

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 4 , to further elaborate the present invention.

[0028] An automatic sample-dividing robot for grain detection, comprising a bracket 1, a fixed casing 2, a sample-dividing mechanism 3 and a vibrating mechanism 4, a fixed casing 2 is installed on the bracket 1, and a sample-dividing mechanism is installed in the fixed casing 2 Mechanism 3, a vibrating mechanism 4 is installed in the sampling mechanism 3; wherein:

[0029] The fixed housing 2 includes a lower material cylinder 21, a limit cylinder 22, a telescopic plate 23, an adjustment frame 24 and a guide plate 25. The lower material cylinder 21 is installed on the upper end of the bracket 1, and the lower material cylinder 21 is a hollow cylinder with a hollow front end opening. Type structure, the rear end of the lower barrel 21 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com