High-precision low-noise power supply design method

A technology of low-noise power supply and design method, which is applied in the direction of electrical components, adjustable electric variables, instruments, etc., and can solve the problems of increasingly high requirements for power supply performance and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

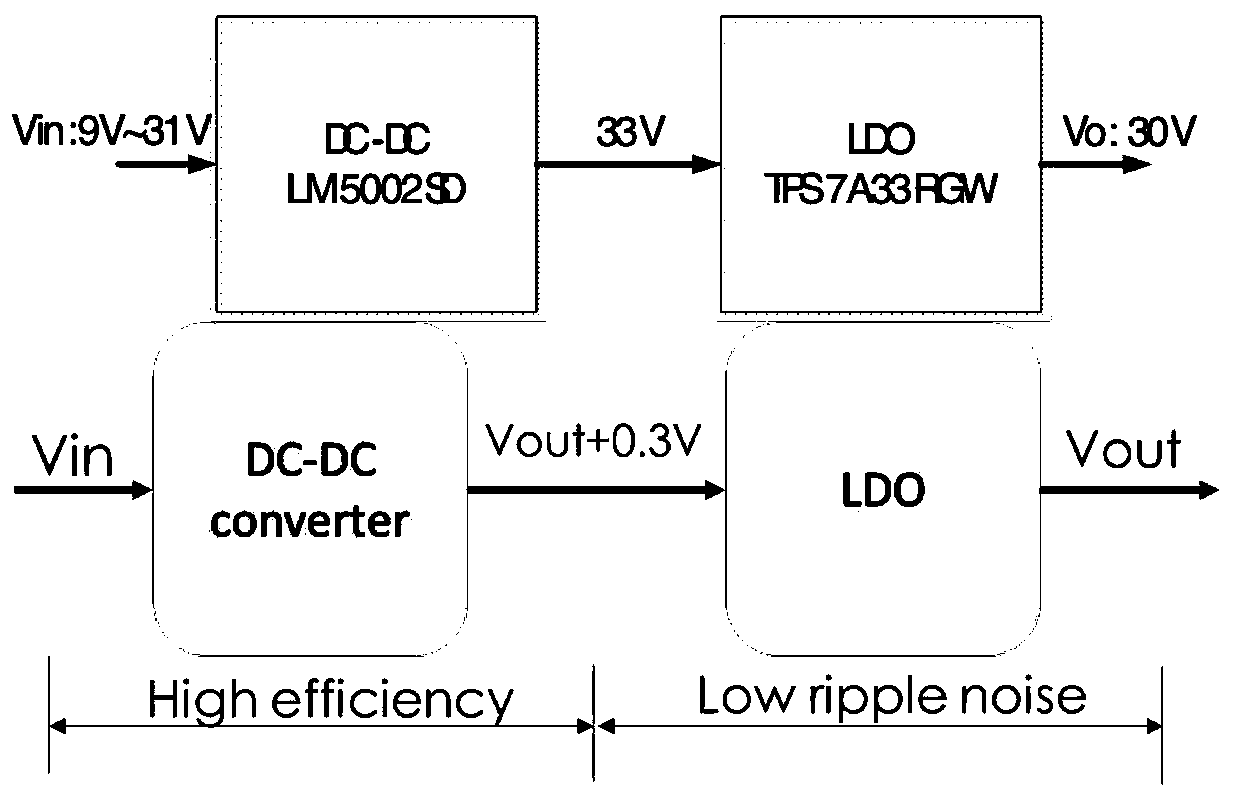

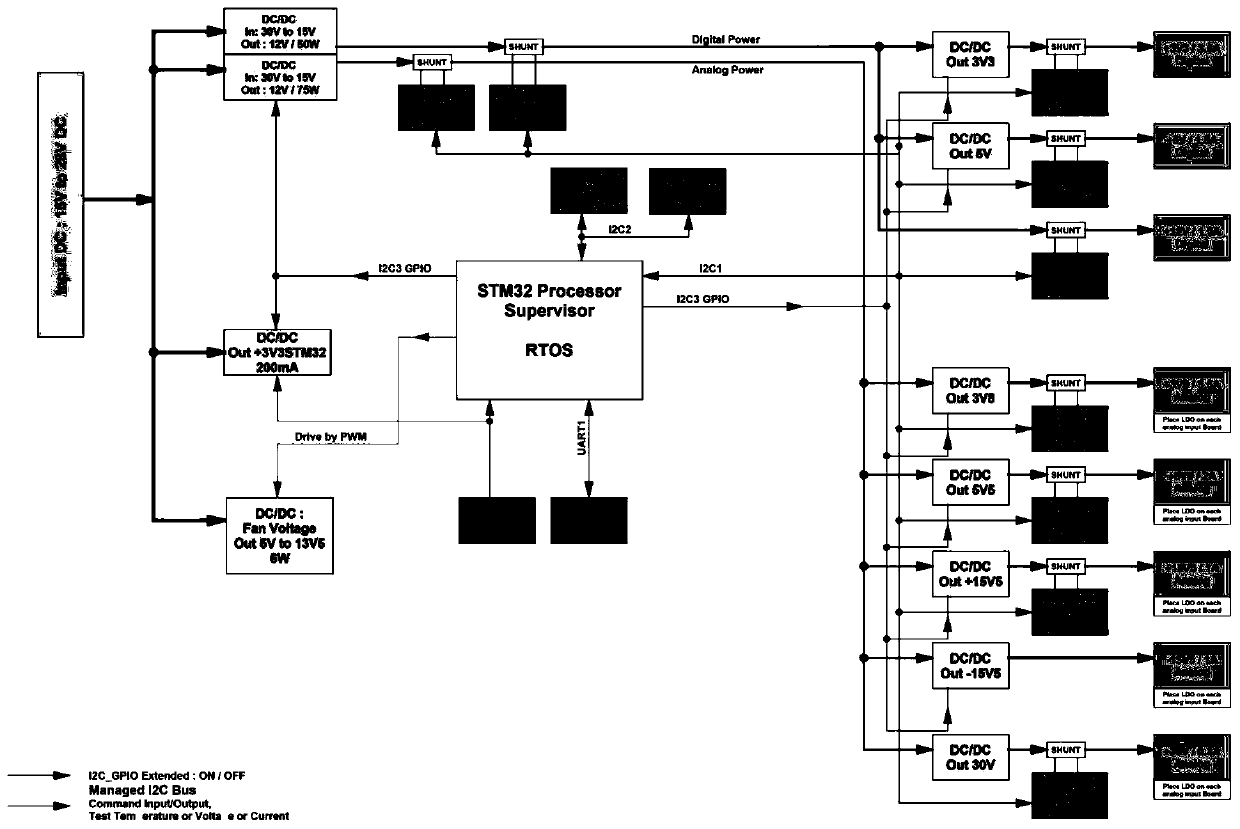

[0025] This embodiment provides a method for designing a high-precision and low-noise power supply. see Figure 2-4 Shown is a specific embodiment of the high-precision low-noise power supply design method in this application, including:

[0026] figure 2 The input circuit adopts different power supply circuits for different acquisition signals, such as digital signal and analog signal, digital power supply (Digital power) and analog power supply (Analog power). In addition, for each DC / DC output, the signal is fed back to the STM32Processor superior through the Measures V / I 12C BUS for management, and then the DC / DCin is controlled to form a closed loop.

[0027] image 3 For the power path management circuit, LT1377 is selected as the 28V, ±15V, +5V and +3.3V power supply chip, and the required voltage is obtained by configuring different feedback resistors; and A CT8945AQJ405 is selected as the power management chip of the ARM MCU.

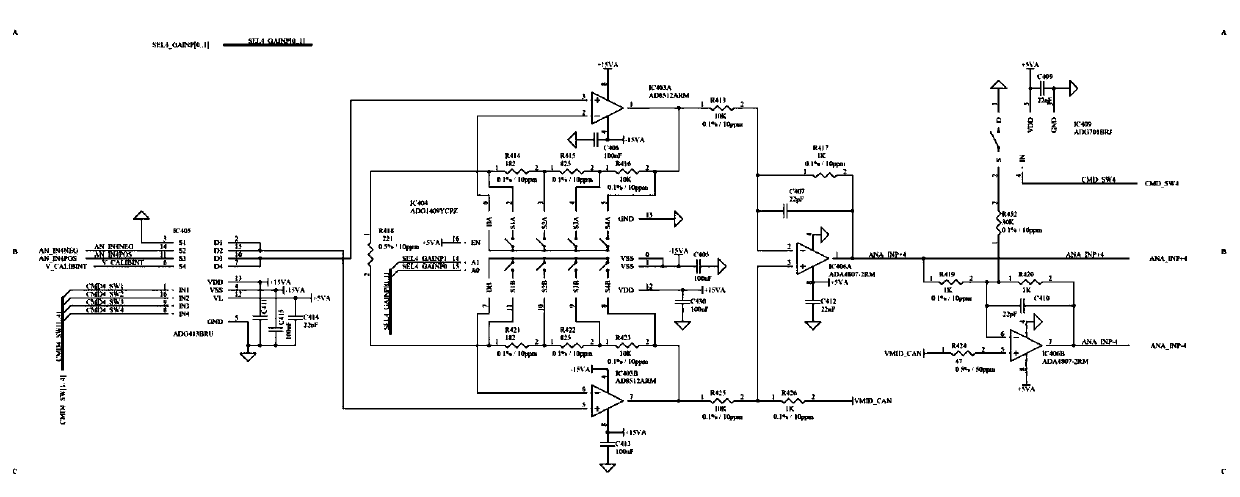

[0028] Figure 4 MCU control circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com