Prevention sytem for overhoist of crane

A technology of cranes and landing gear, which is applied in cranes, transportation and packaging, etc., and can solve the problems of low efficiency in installation operations or disassembly and finishing operations, and masts that cannot be erected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment -

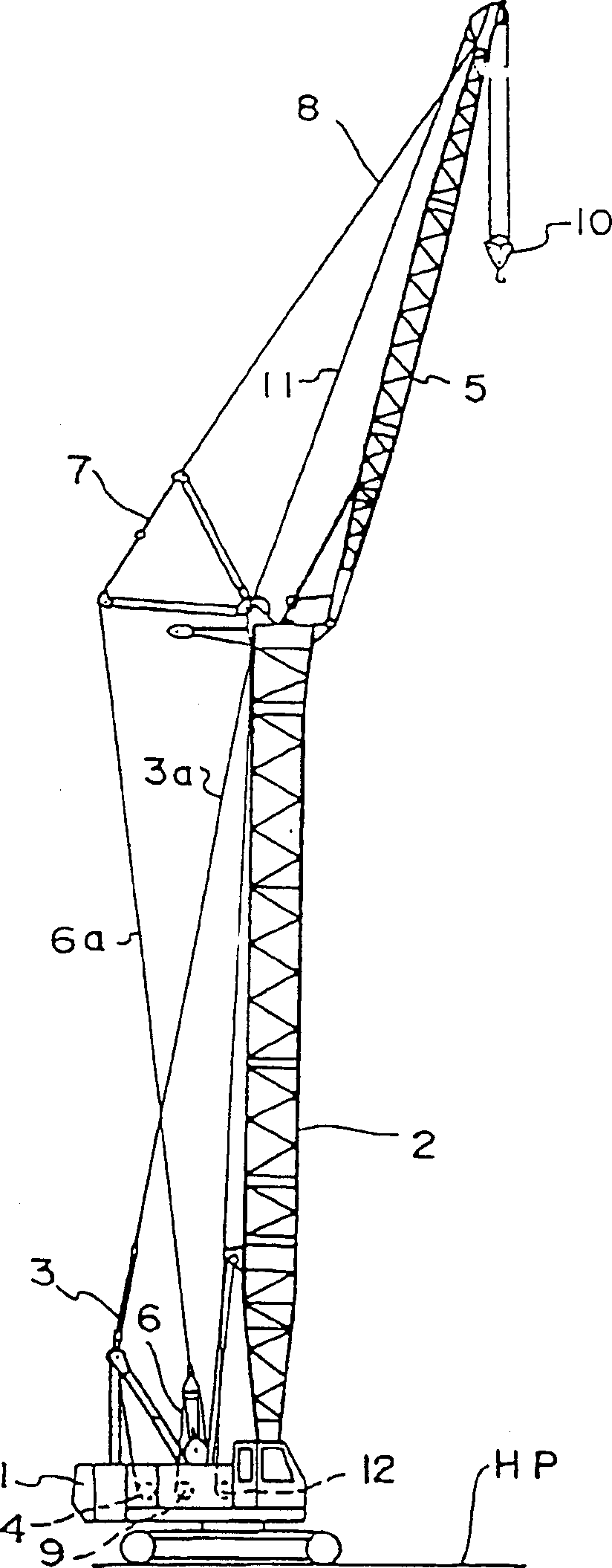

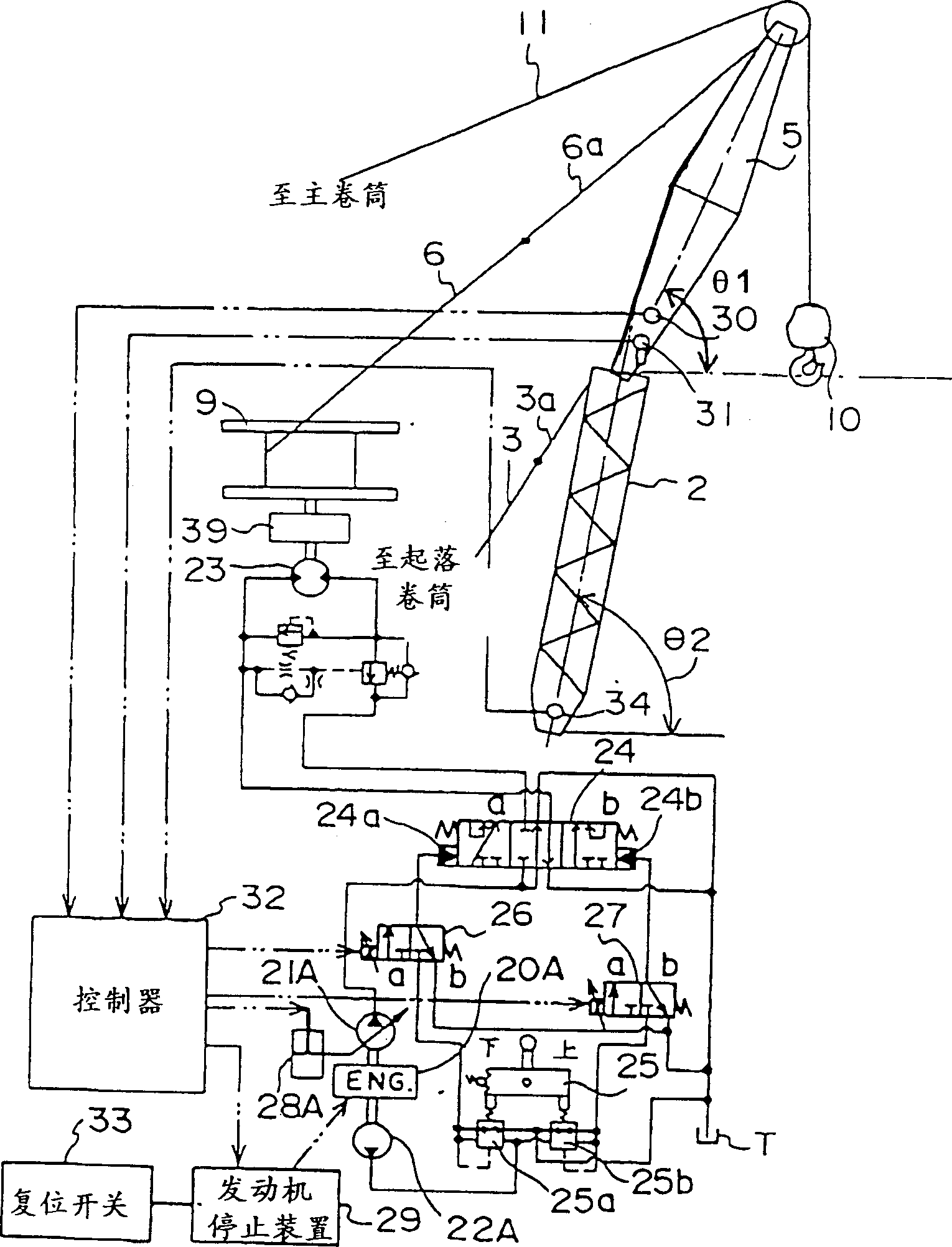

[0067] refer to Figure 1 to Figure 5 The first embodiment of the present invention will be described. figure 1 It is a schematic structural diagram showing the tower crane related to the first embodiment of the present invention. Such as figure 1 As shown, the tower crane related to the first embodiment has: a crane body 1, equipped with a mobile body and a rotating body arranged on the mobile body; a mast 2, connected to the crane body 1 in a freely pitching manner; The mast lifting reel 4 makes the hanger lifting wire rope 3 connected by the hanging wire rope 3a installed on the upper end of the mast 2 be rolled in or released, so as to make the mast rise and fall; Freely connected to the upper end of the mast 2; and the hook 10, utilizes the hoisting main reel 12 provided on the crane body 1 to draw in or release the hoisting wire rope 11 for lifting. A swing arm 7 is arranged on the upper end of the mast 2 . The simple structure of the jib 7 is that three components a...

no. 2 Embodiment -

[0089] In the first embodiment above, in Figure 6 Immediately after switching the proportional pressure reducing valve 27 to the b side in step S13 of the shown flowchart, the engine 20A is stopped in step S14, but the following processing may be performed after the proportional pressure reducing valve 27 is switched to the b side.

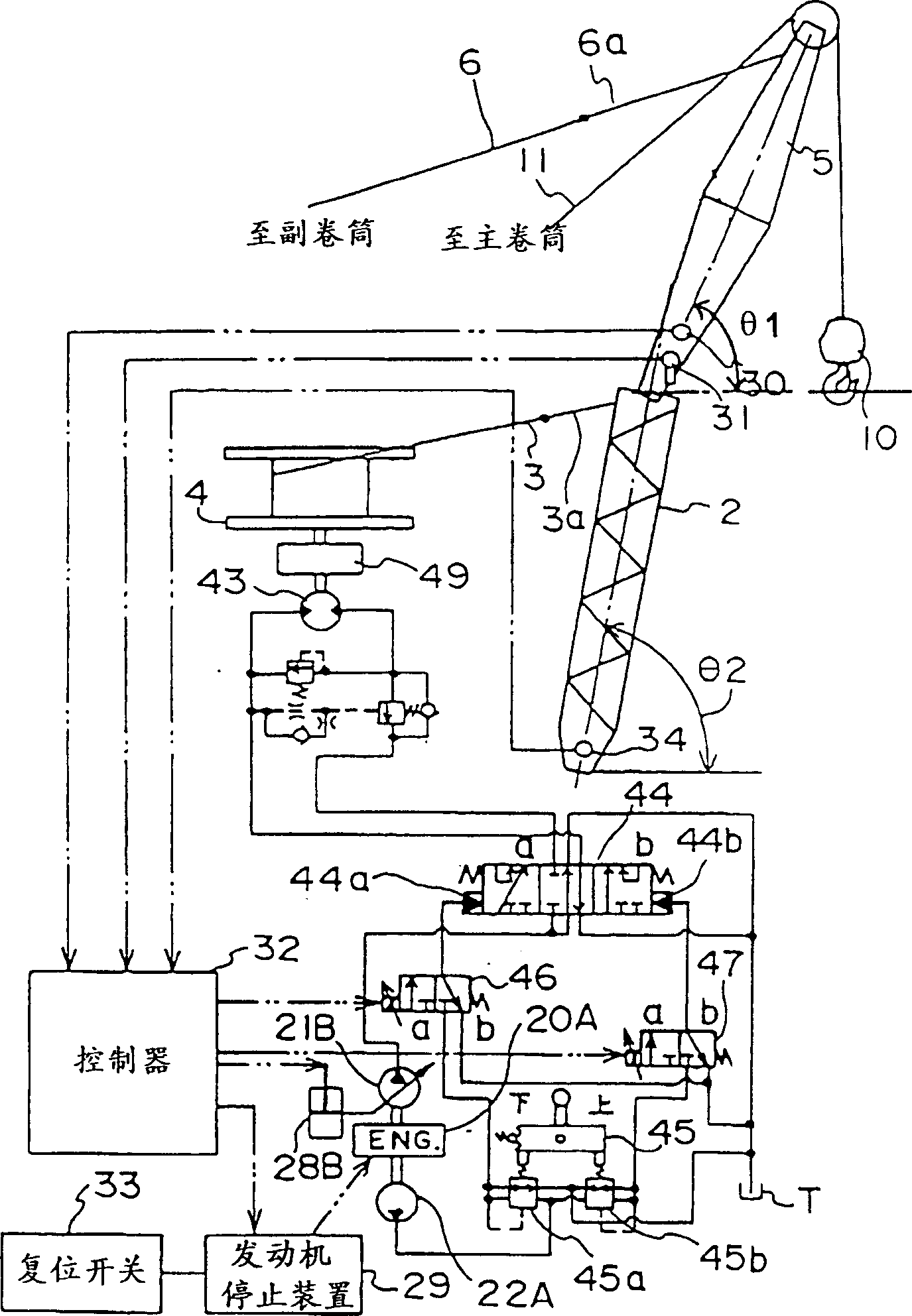

[0090] That is, if Figure 10 ~ Figure 12 As shown, in the hydraulic circuit for lifting the boom 5, lifting the mast 2, and lifting the hook 10, the auxiliary winch motor 23 and the main winch motor 53 are rotated forward and the lift motor 43 When reversing (the direction in which the boom 5 is erected, the mast 2 is fallen, and the hook 10 is raised), pressure detectors 61, 62, and 63 are respectively arranged on the pipelines supplying pressure oil to each motor, and the pressure detectors 61, 62, 63 pairs in Figure 6 Whether each motor 23, 43, 53 rotates after step S13 is detected.

[0091] Figure 13 It is a flowchart showing processin...

no. 3 Embodiment -

[0096] For cranes, when performing preparatory work, that is, installation work, before starting lifting operations, etc., to enable the crane to work, it is sometimes necessary to release the above-mentioned overwinding prevention device. During this installation work, it is also possible to perform the following the work described.

[0097] The oil pressure circuit and figure 2 Shown are the same, drive the hydraulic circuit of the mast lifting drum 4, such as Figure 14 shown. exist Figure 14 in, with image 3 The same components are shown with the same symbols. The description of the structure already explained is omitted.

[0098] Such as Figure 14 As shown, a pressure detector 51 is provided on the pipeline between the proportional pressure reducing valve 27 and the pilot valve 45b of the hydraulic circuit that drives the mast lifting drum 4, and a pressure detector 51 is provided on the mast 2 for detecting that the mast angle θ2 has reached The microswitches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com