air filter media

An air filter and filter material technology, which is applied in the field of air filter material, can solve the problems of air filter material being easily electrified, and achieve the effects of pressure loss, low pressure loss, and high electrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

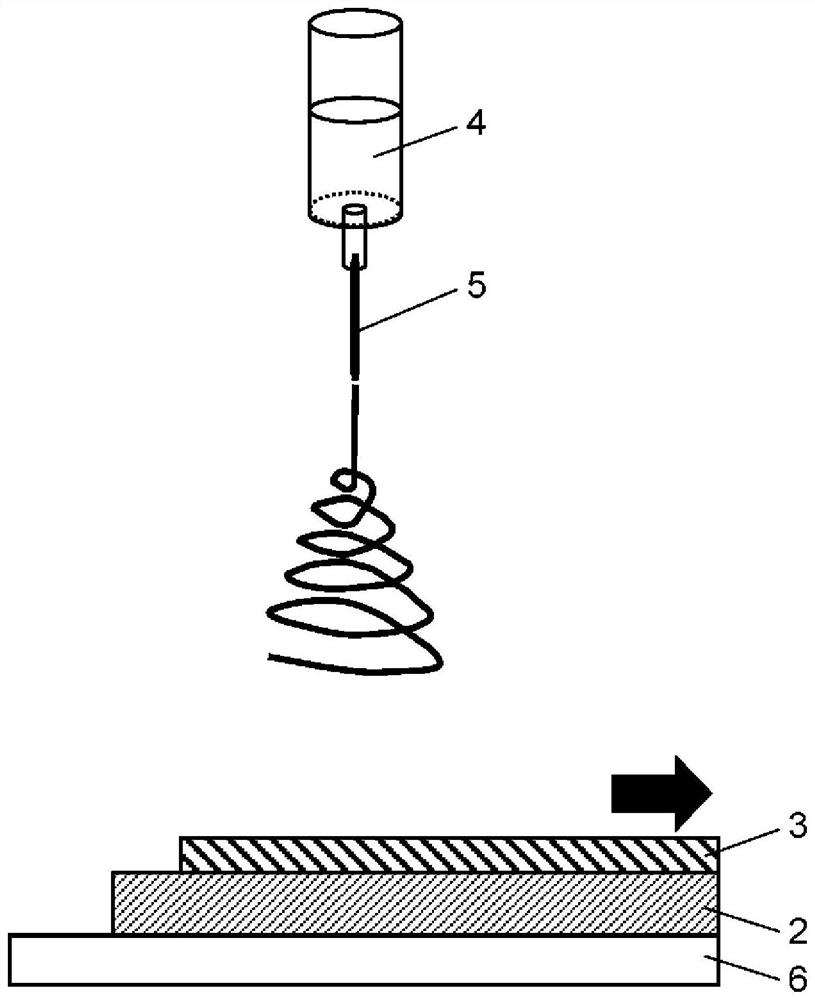

[0030] Hereinafter, embodiments of the air filter medium of the present invention will be described with reference to the drawings. In addition, the content demonstrated below is only an example of implementation, and is not limited to this.

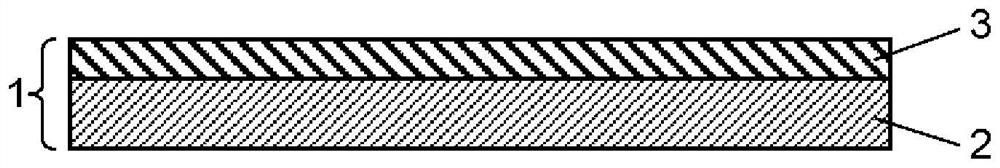

[0031] figure 1 It is a schematic diagram showing the laminated structure of the air filter media. Such as figure 1 As shown, the air filter material 1 has a structure including a base material layer 2 and a fine fiber layer 3 provided on the upper surface of the base material layer 2 and having chargeability.

[0032] The base material layer 2 constituting the air filter medium 1 is formed of glass fibers, pulp fibers, resin fibers, carbon fibers, inorganic fibers, or at least one of these fibers. Examples of the method for producing the base material layer 2 include a spunbond method, a dry or wet papermaking method, a melt blown method, a spunbond method, an air-laid method, a thermal bonding method, and the like.

[0033] Regardi...

reference example 1

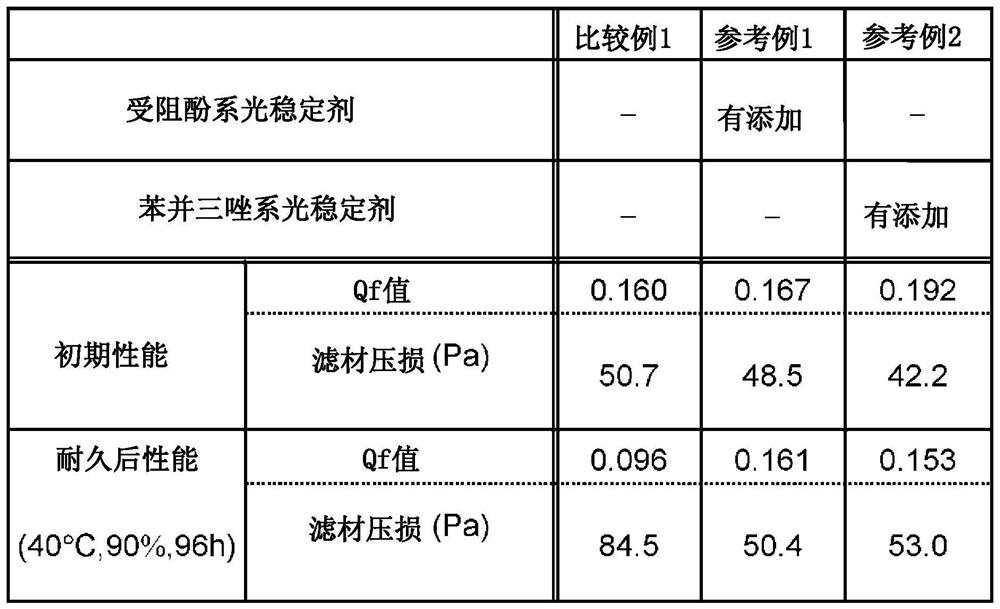

[0065] An air filter medium is manufactured using the manufacturing method described in this embodiment. Polystyrene was used as a polymer raw material, and polystyrene was dissolved in N,N-dimethylacetamide to prepare a 20% by weight polystyrene solution. A small amount of Irganox 565, which is a hindered phenolic light stabilizer, was added to this solution to obtain a spinning solution.

[0066] Thereafter, the above-mentioned spinning solution was spun by using an electrospinning method to obtain an air filter material having a fine fiber layer formed on the substrate layer.

[0067] Next, perform the above-mentioned performance evaluation, in image 3 Indicates its result.

reference example 2

[0069] Using the same method as in Reference Example 1 above, a 20% by weight polystyrene solution was produced. A small amount of Tinuvin 326 as a benzotriazole-based light stabilizer was added to this solution to obtain a spinning solution.

[0070] Thereafter, an air filter material was obtained by using an electrospinning method.

[0071] Next, the same performance evaluation as that of Reference Example 1 was carried out. image 3 Indicates its result.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com