Pressed film rope fixing method for preventing greenhouse plastic film from rapid abrasion

A technology of plastic film and fixing method, which is applied in the fields of botanical equipment and methods, horticulture, greenhouse cultivation, etc., can solve the problems of integral destruction of plastic film, no tightening of laminating rope, damage of plastic film, etc. Manual repair process, fast and convenient installation, and the effect of avoiding direct friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The concrete steps of the inventive method are:

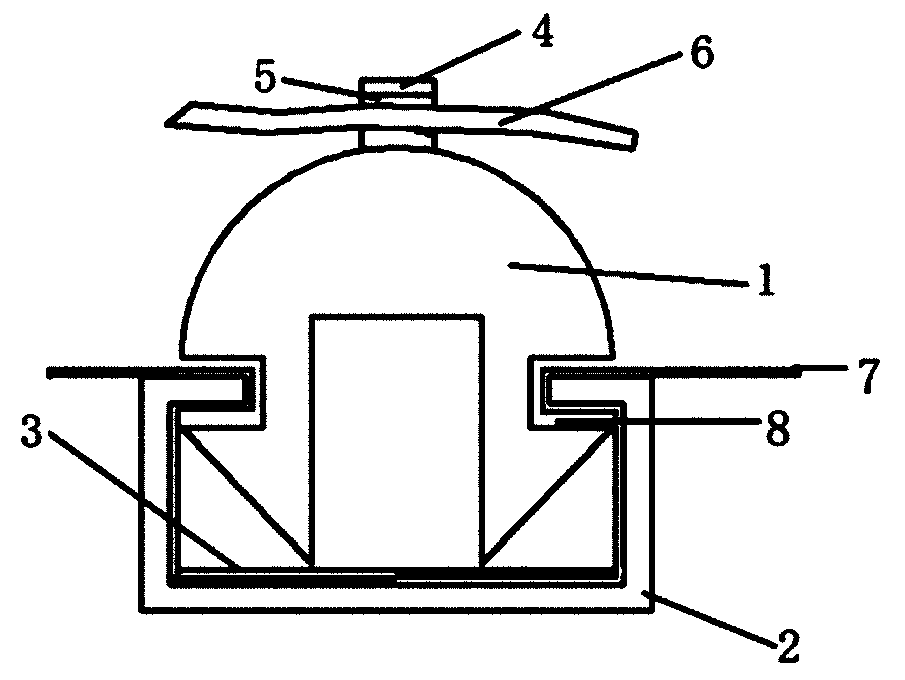

[0013] (1) After the framework of the agricultural greenhouse is built, the slot 2 is welded and fixed between the adjacent frameworks;

[0014] (2) Lay the plastic film 7 on the outside of the greenhouse frame, insert the plastic film 7 into the card slot 2, insert the S-shaped clip spring 3 into the card slot 2, and fix the plastic film 7 of the greenhouse on the card slot 2 to prevent When the wind blows, repeated friction between the plastic film and the frame of the greenhouse causes damage;

[0015] (3) Design a U-shaped snap ring according to the shape and size of the upper port of the card slot 2. The U-shaped snap ring includes a U-shaped clip 1 and a rope ring 4; there are longitudinal side grooves 8 on the outer sides of the U-shaped clip 1. The size of the groove 8 matches the opening size of the upper end of the supporting card slot 2; a rope ring 4 is arranged above the top of the U-shaped card, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com