Taper-angle self-adaption atomizing fan-type nozzle based on precise variable spraying system

A spray system and fan-shaped nozzle technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of different atomization degree of droplets, uneven distribution of droplets, and affecting spray quality, so as to achieve novel structure and improve spray uniformity , reduce the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

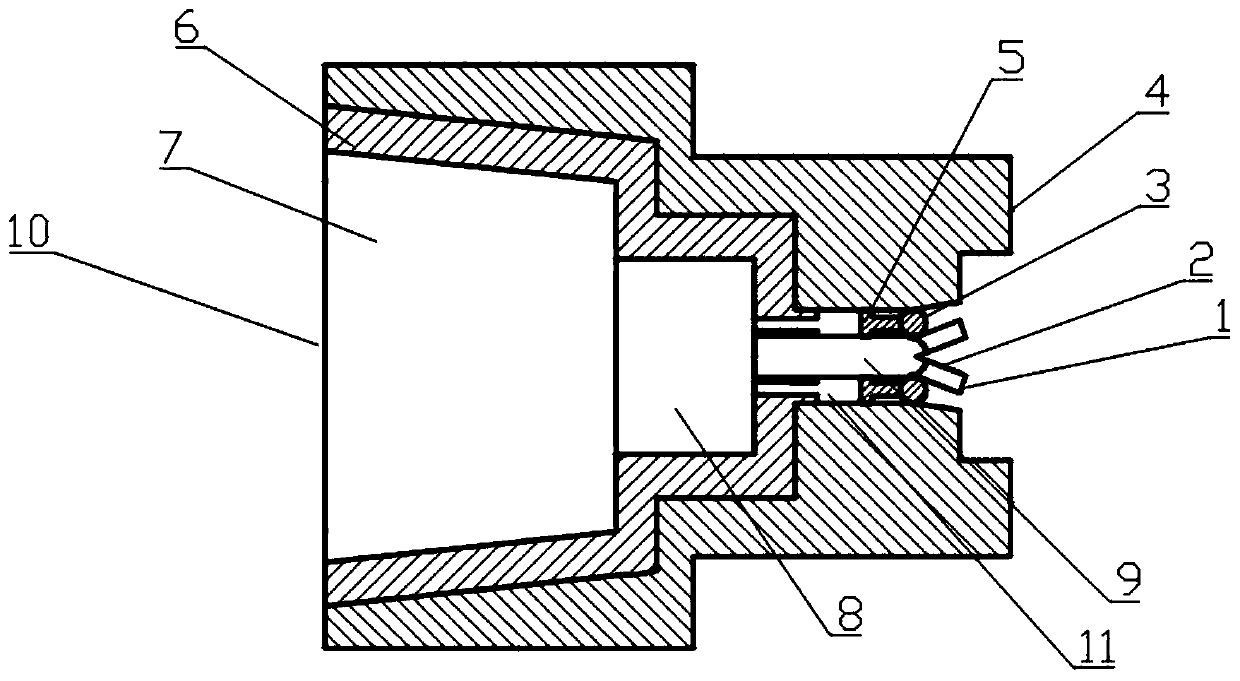

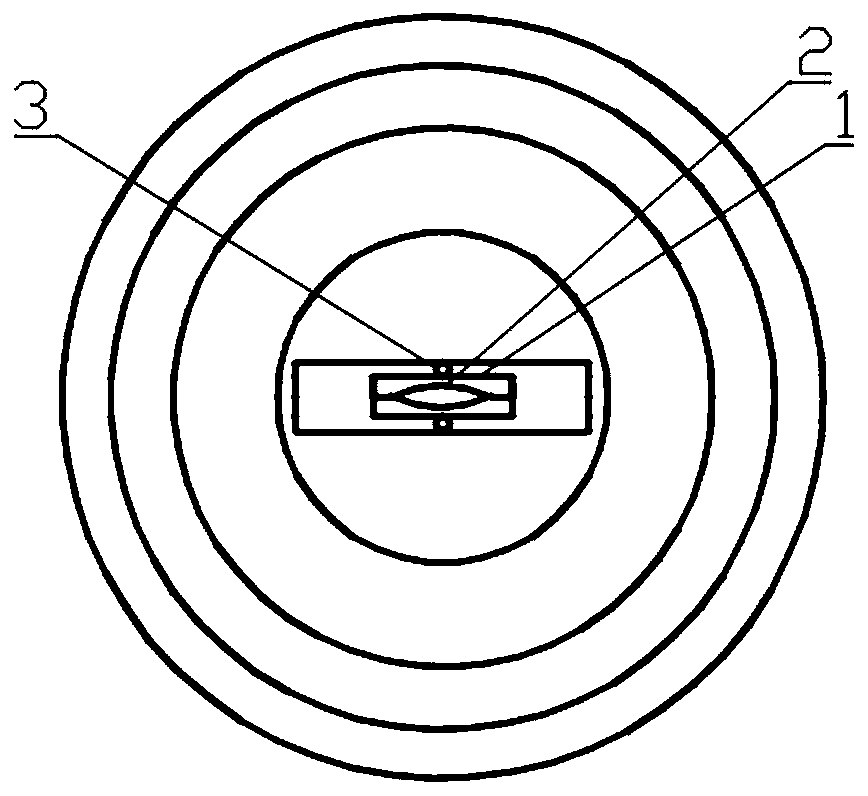

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A cone-angle self-adaptive atomizing fan-shaped nozzle based on a precise variable spray system. A liquid outlet 2 is opened at one end of the nozzle body. The liquid outlet 2 is a long and narrow rugby-ball-shaped gap opened outside the nozzle head 1 . There are three levels of cylindrical flow channels inside the fluid pipeline, and they are in a decreasing relationship. The diameter of the first level cylindrical flow channel 7 is greater than the diameter of the second level cylindrical flow channel 8, and the diameter of the second level cylindrical flow channel 8 is larger than that of the third level. The first-stage cylinder runner 9 and the axis of the third-stage cylinder runner are kept on a straight line. The stable atomization regulating flow channel is opened at the junction of the second-stage cylindrical flow channel and the inner nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com