Automatic cleaning device for air cooling air compressor cooler

A technology for automatic cleaning and cooling, which is applied to the cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow. The effect of failure, reduction of human resource waste, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

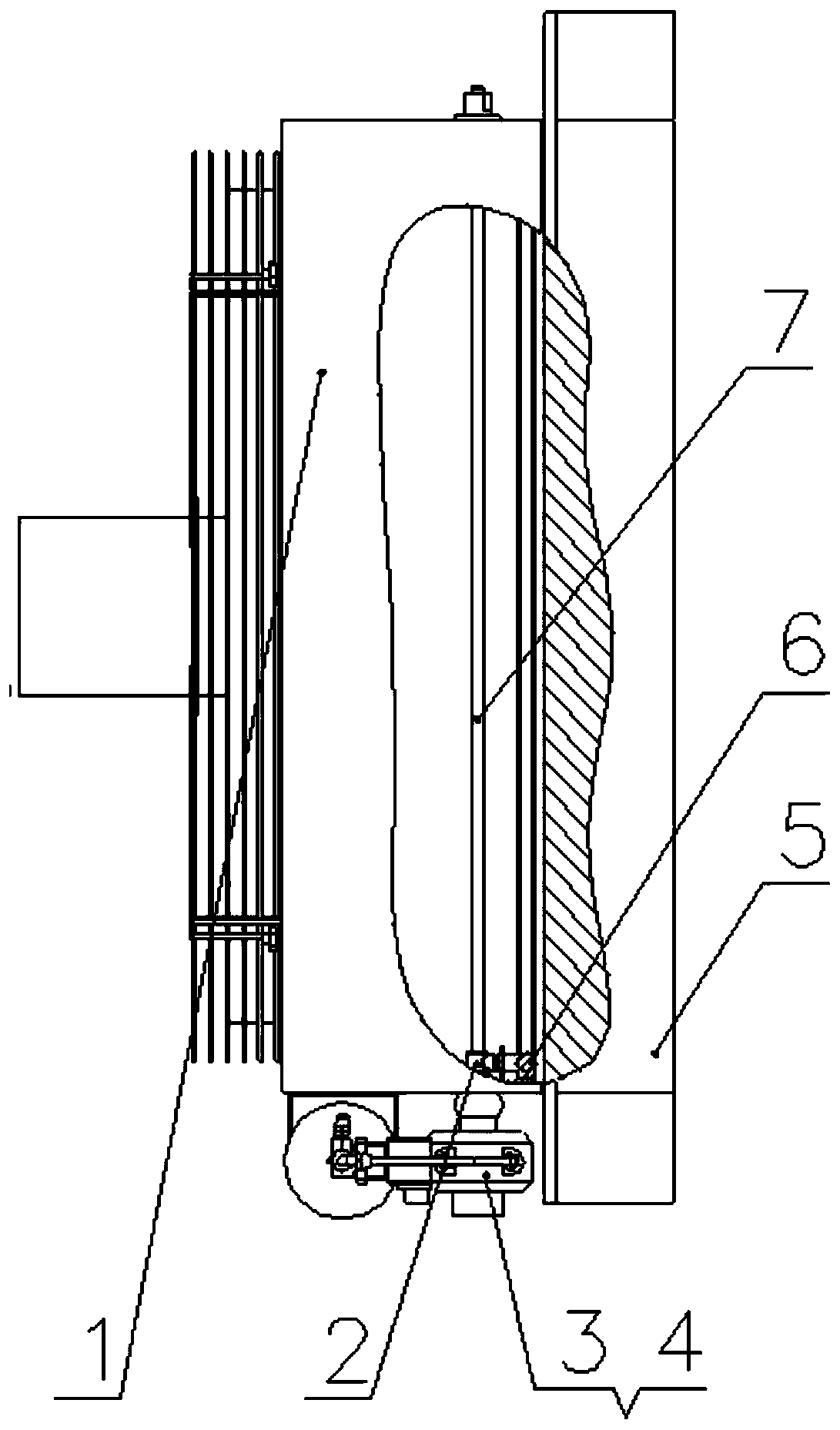

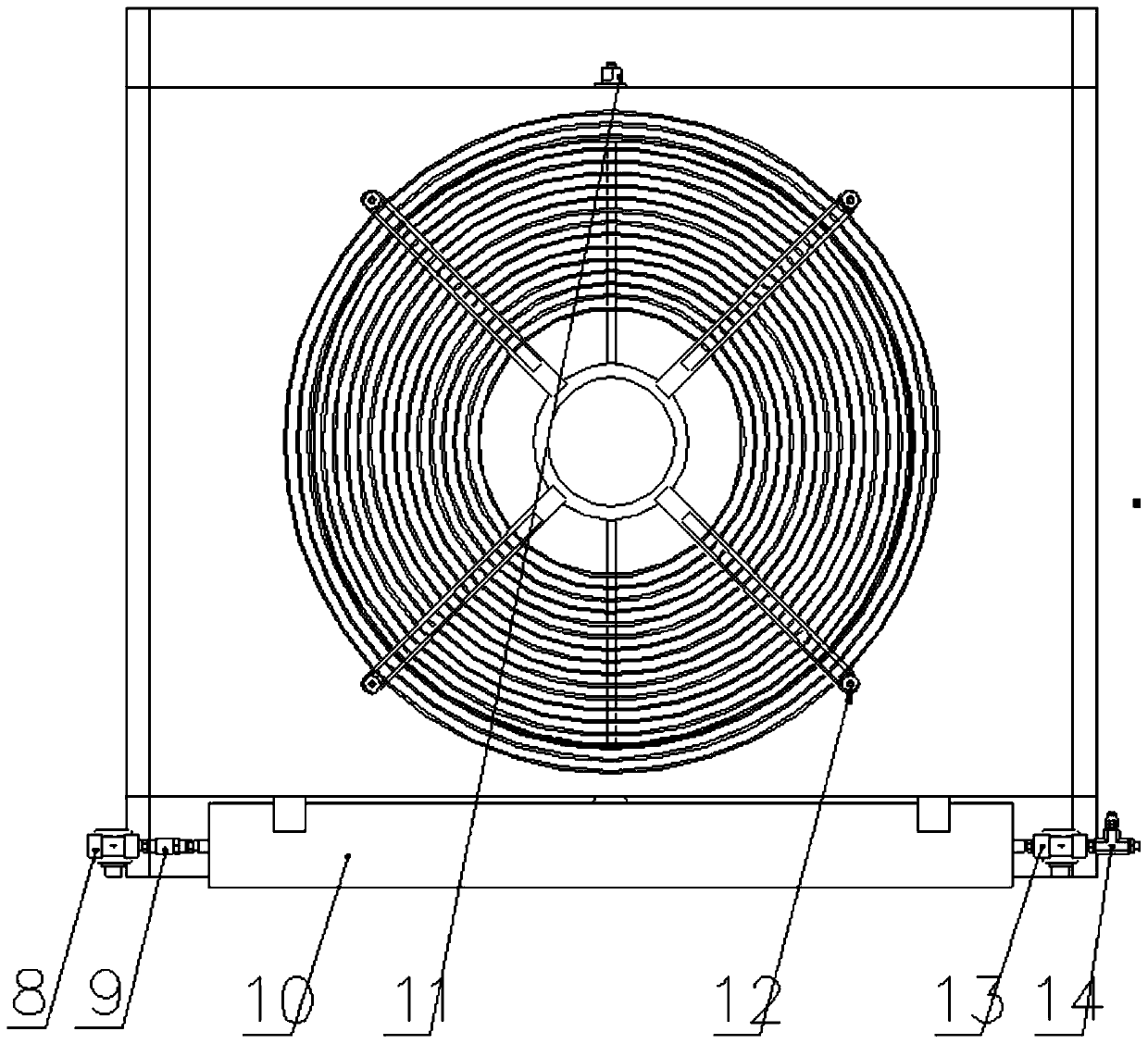

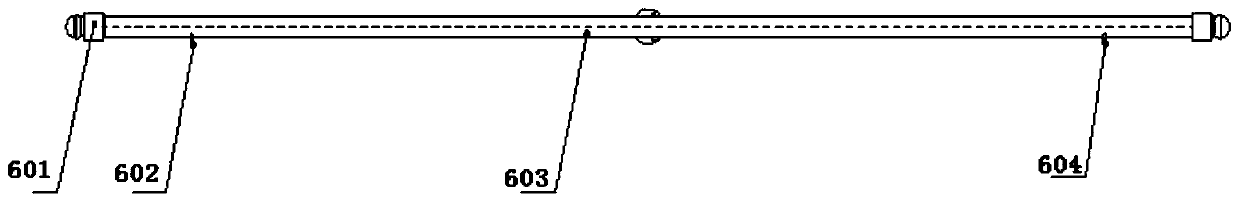

[0029] see Figure 1-Figure 5 , an automatic cleaning device for an air-cooled air compressor cooler, including a pressure gas source, the pressure gas source is divided into two paths: one path communicates with the solenoid valve b13, the solenoid valve b13 communicates with the air motor 17, and the air motor 17 It is connected with the slider nut 2; the other way is directly connected with the cleaning rod 6; the slider nut 2 is fixedly connected with the cleaning rod 6, and cooperates with the screw rod 7; The bottom of the windshield is fixedly connected; the cleaning rod 6 is perpendicular to the screw rod 7; the solenoid valve b13 is opened, the air motor 17 is turned on, driven by the starter motor 17, the cleaning rod 6 overcomes the tension of the extension spring 2 and moves along the screw rod with the slider nut 2 7 straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com