Diatomite selecting throwing machine device

A technology of throwing machine and diatomite, which is applied in the direction of throwing machine, transportation and packaging, etc., can solve the problems of high temperature resistance, enterprise loss, diatomite quality is difficult to guarantee, etc., and achieve the effect of simple structure and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

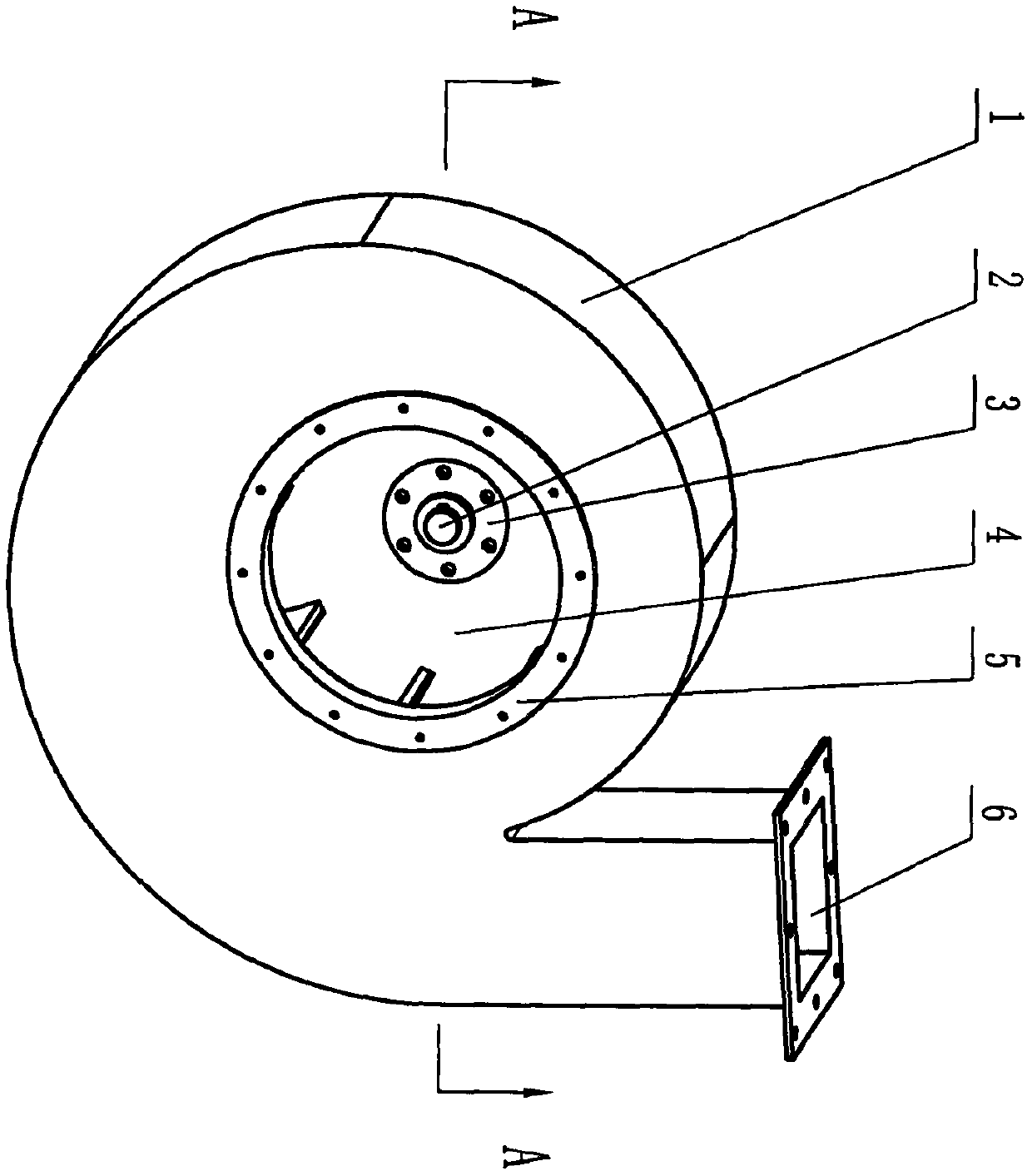

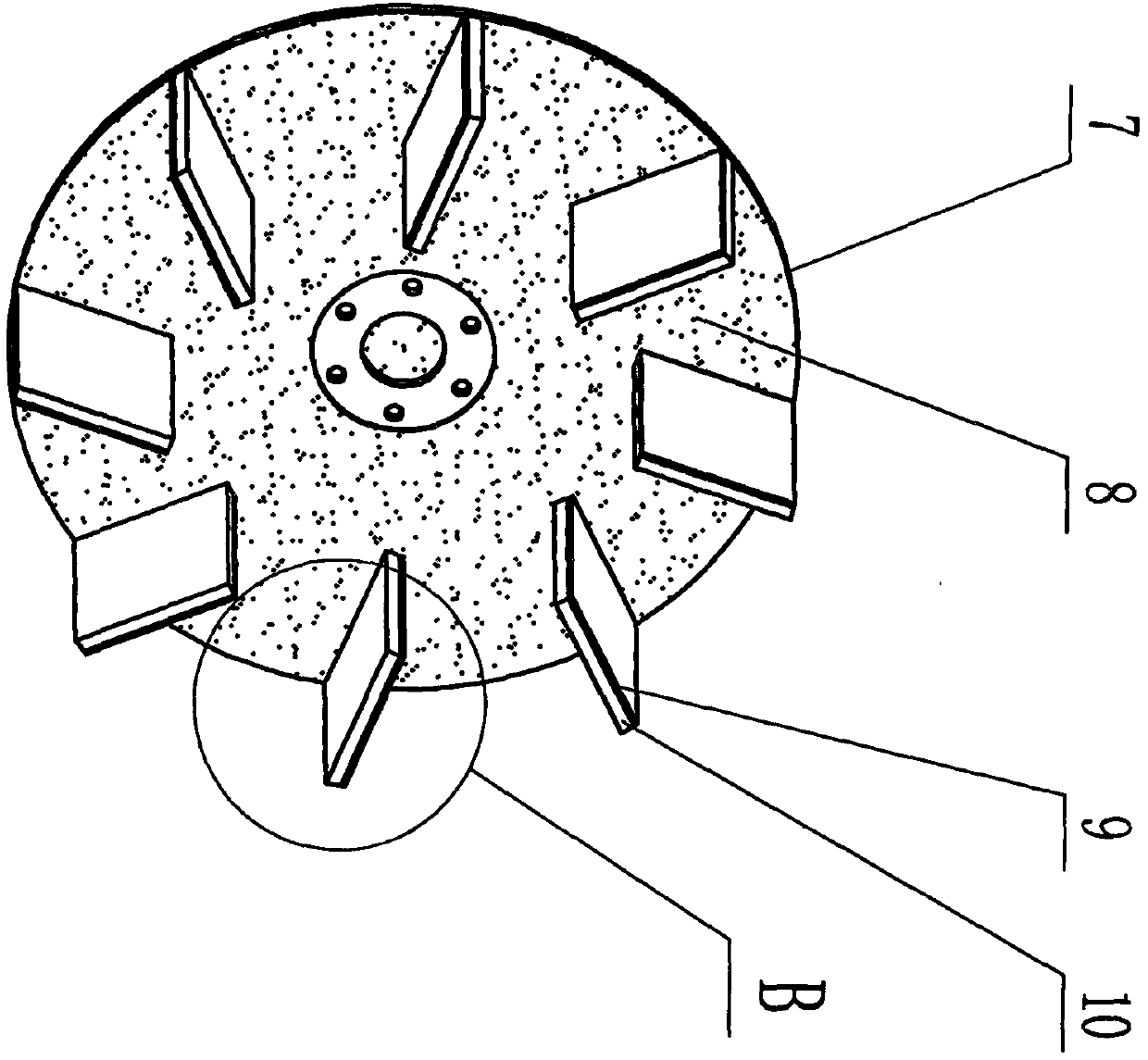

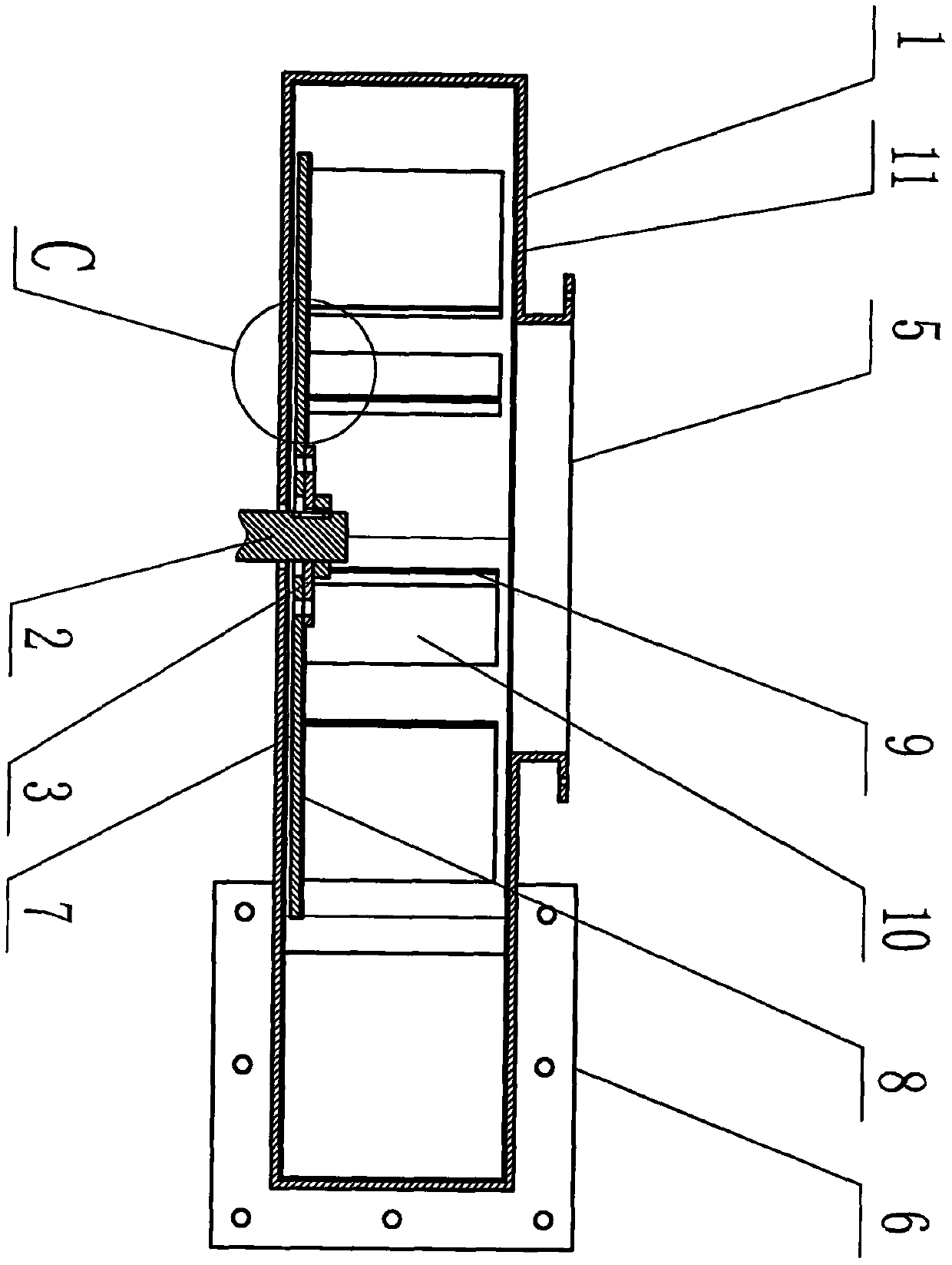

[0015] Refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , The caster shell 1 is inlaid with a shell wear-resistant layer 11, the caster shell 1 is provided with an inlet 5 and an outlet 6, the caster wheel 4 is connected with the connecting piece 3, and the connecting piece 3 is connected with the The feeding wheel shaft 2 is connected by a key, and the throwing wheel 4 is assembled inside the shell 1 of the throwing machine. After the throwing wheel shaft 2 is powered, it can drive the throwing wheel 4 to rotate in the set direction; the throwing wheel main board 7 is connected to the throwing wheel. The main plate 10 constitutes the casting wheel 4, the main plate 7 of the casting wheel is inlaid with a wear-resistant layer 8 of the main plate, and the wear-resistant layer 9 of the casting plate is inlaid on the main plate 10; 8. The material of the wear-resistant layer 9 of the cast sheet is emery block or electroplated emery.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap