Installing device and method for inclinometer tubes in concrete diaphragm wall

A concrete anti-seepage wall and installation device technology, which is applied in the direction of measuring device, measuring inclination, surveying and navigation, etc., can solve the problems of bending of the inclinometer pipe, affecting the monitoring effect, and the inclinometer pipe cannot be fixed, so as to ensure the accuracy and reliability, the effect of length science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

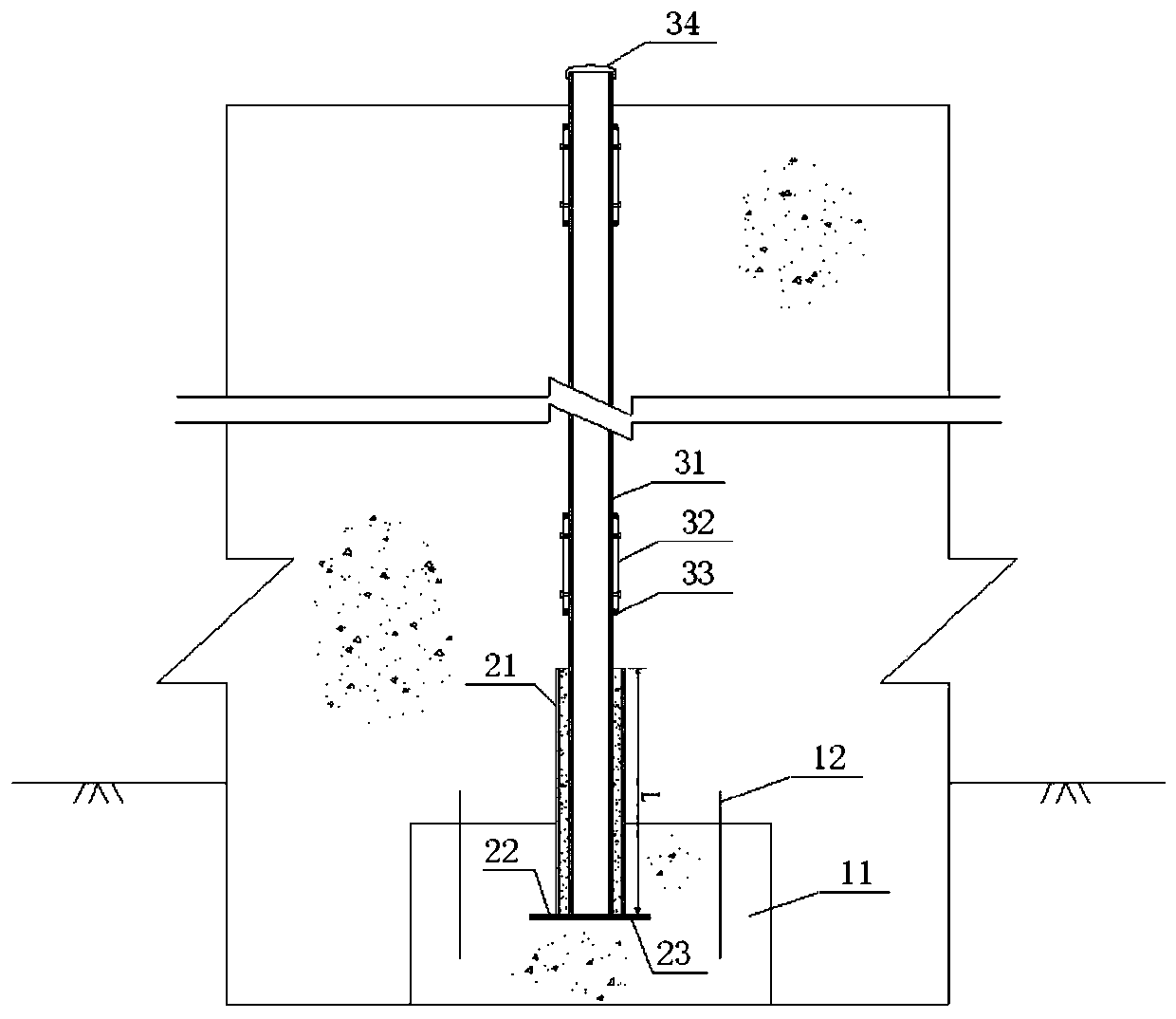

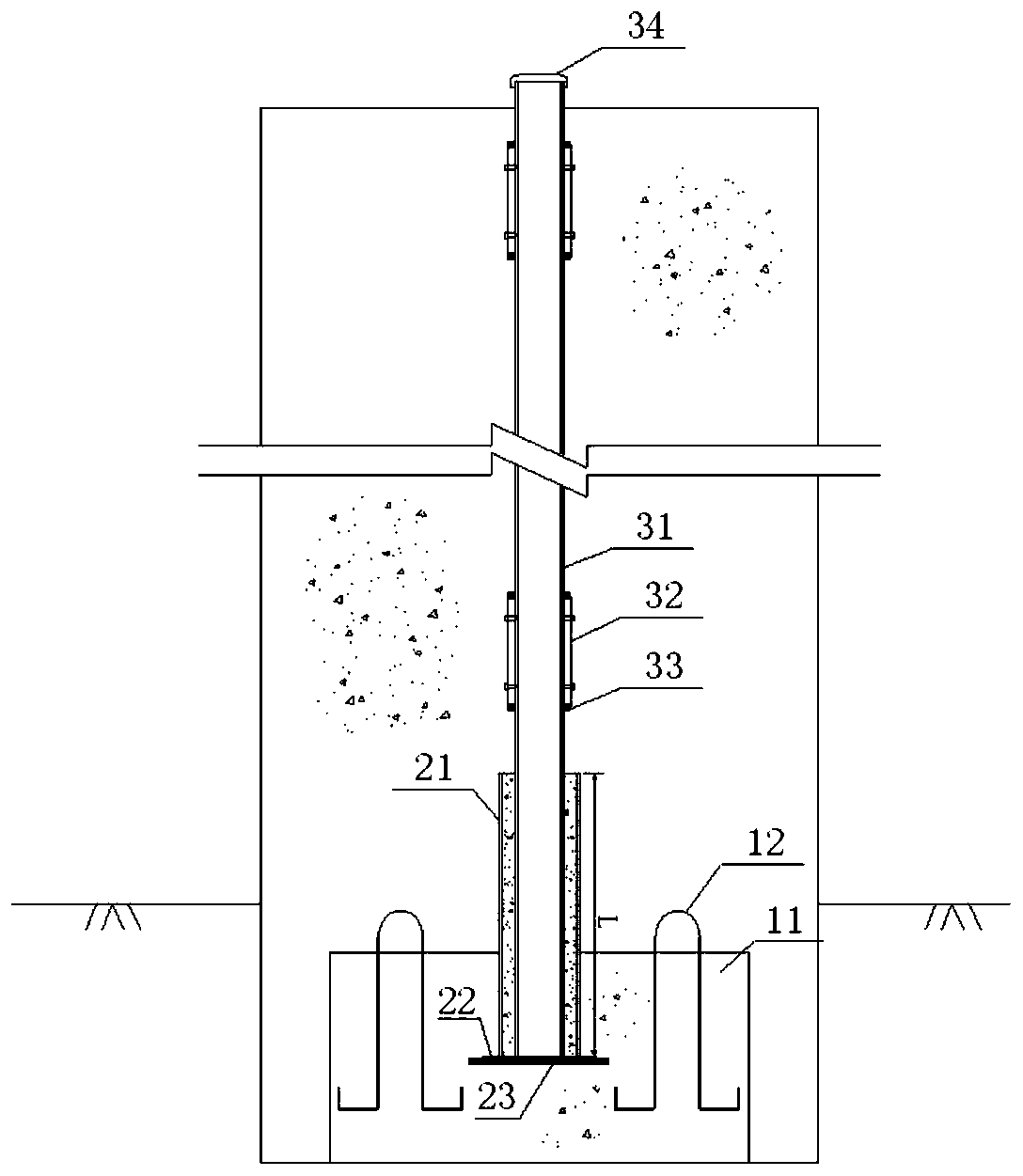

[0035] Such as figure 1 , figure 2 As shown, an installation device for inclinometer pipes in a concrete anti-seepage wall of the present invention includes several inclinometer pipes 31, galvanized steel pipes 21, and concrete heavy blocks 11. The bottom of the inclinometer pipes 31 is inserted into a galvanized steel pipe 21, the bottom of the galvanized steel pipe 21 is poured in the concrete heavy block 11. The inclinometer tube 31 is generally made of ABS material, the bottom is inserted into a galvanized steel pipe 21, and the inclinometer tube 31 is located in the middle of the galvanized steel pipe 21, and the inclinometer tube 31 and the galvanized steel pipe 21 are separated by cement mortar. layer backfill. The inclinometer tubes 31 are connected by connecting sleeves 32 , and the inner diameter of the connecting sleeves 32 is the same as the outer diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com