MVR centrifugal steam compressor air inlet anti-surge pipe

A steam compressor, centrifugal technology, applied in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of high manufacturing cost and complex structure, achieve simplified structure, reduce compressor efficiency, eliminate surge vibrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

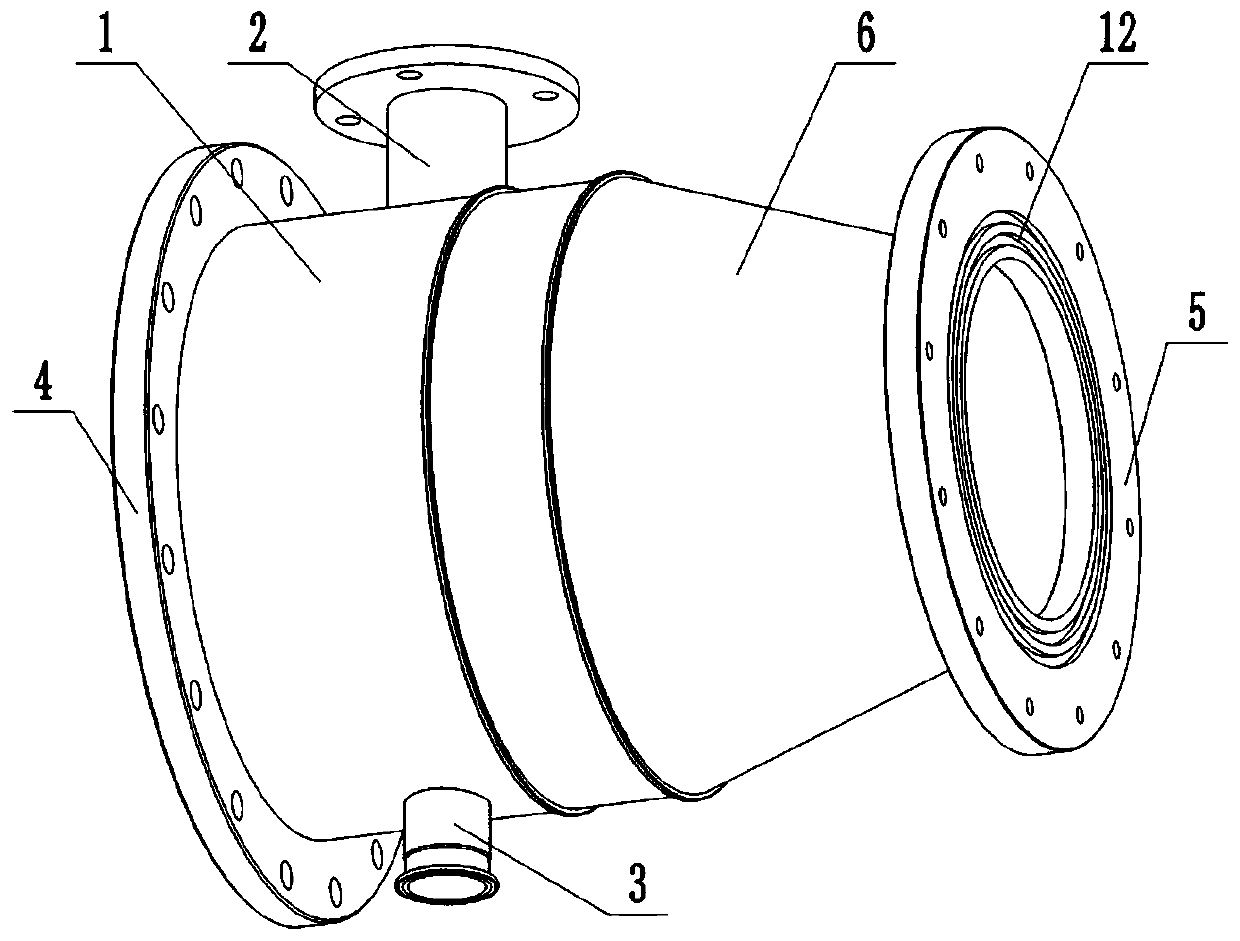

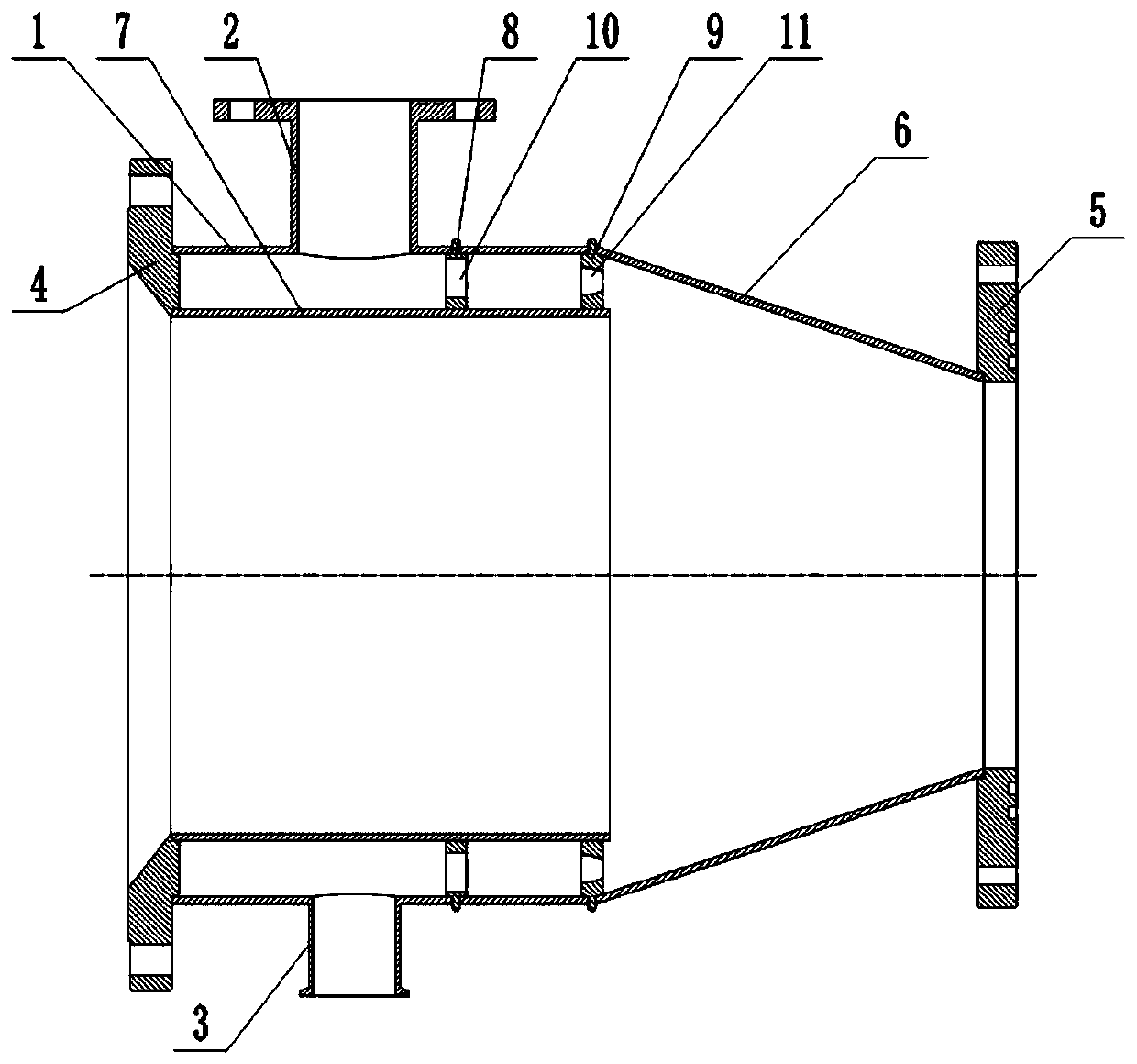

[0028] Basic as attached figure 1 , figure 2 Shown: MVR centrifugal steam compressor intake anti-surge pipe, including air induction tube 1, first air induction pipe 2, second air induction pipe 3, first flange 4, second flange 5, swirl cylinder 6, The inner cylinder 7, deflector 8 and swirl plate 9, the first air induction pipe 2 and the second air induction pipe 3 are all in communication with the air induction cylinder 1, the first air induction pipe 2 is connected to the steam at the exhaust port of the compressor, and the second air induction pipe 3 The second air-introduction pipe 3 is located directly opposite to the first air-induction pipe 2 for external steam supply. The inner cylinder 7 is located inside the air-inducing cylinder 1 and is coaxial with the air-inducing cylinder 1. One end of the chamber formed between the inner cylinder 7 and the air-inducing cylinder 1 is closed by the first flange 4, and the other end is connected with the swirl plate 9. The inne...

Embodiment 2

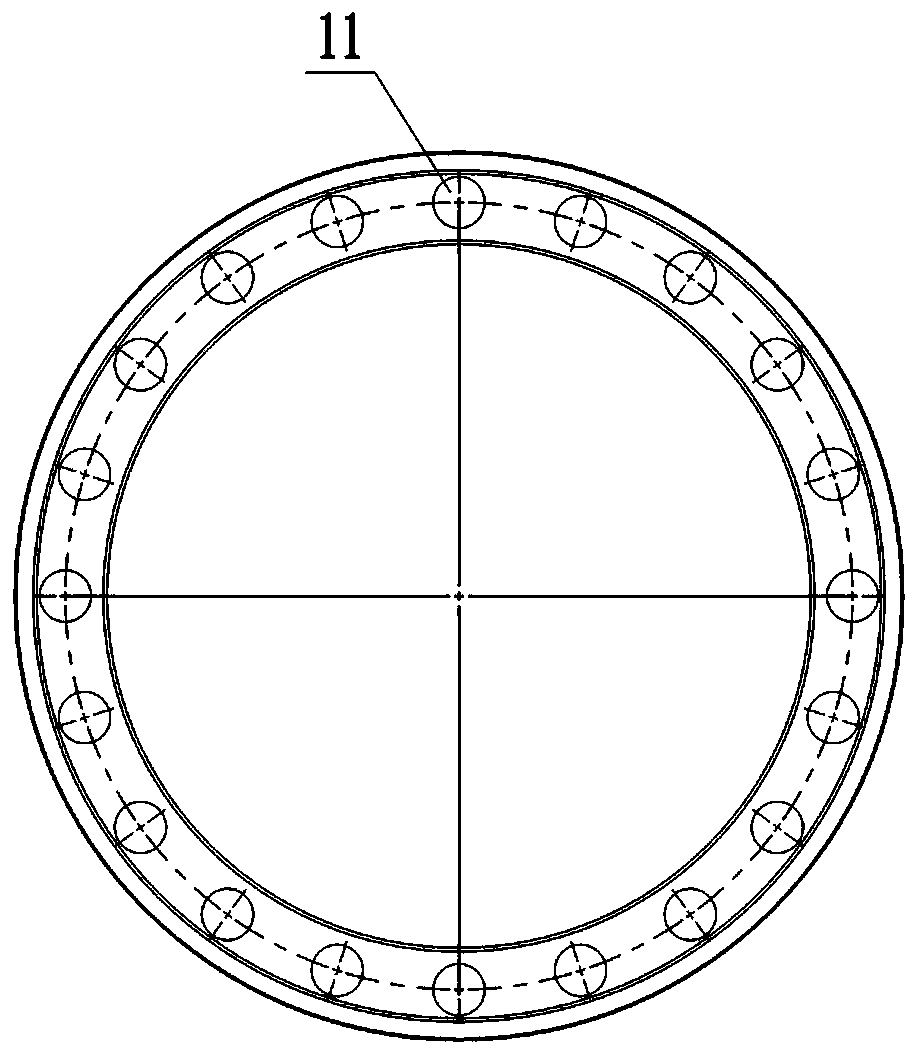

[0032] Compared with Embodiment 1, this embodiment differs only in that: Figure 7 , Figure 8 The swirl holes 11 on the swirl plate 9 shown are nozzle vane-shaped passages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com