Blast cap of fluidized bed furnace

A boiling furnace and air cap technology, which is applied in the field of chemical production, can solve the problems of particle size reduction, strength reduction, air cap eye reduction, etc., and achieves the effect of increasing furnace temperature, increasing hot air volume, and improving operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

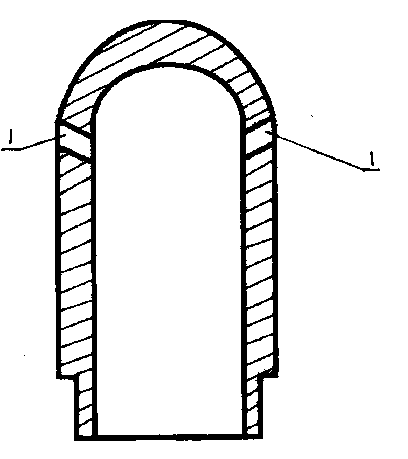

[0016] The present invention has been used on a boiling hot blast stove, and the heat load of the boiling hot blast stove is 3350×10 4 KJ / h, the coal is transported by trolley, and the cinder is transported to the designated storage yard. After research and calculation, it was decided to renovate the previous hood, and increase the diameter of the hood eye (1), that is, from less than 5mm to 6-7mm in order to increase its ventilation and provide sufficient The amount of hot air, thereby improving the output and product quality.

[0017] A fluidized fluidized furnace hood structure of the present invention is as attached figure 1 As shown, a fluidized furnace air cap is cylindrical and has an air cap eye 1 on it, which is characterized in that the diameter of the air cap eye 1 is 6-7mm.

[0018] Effectiveness analysis:

[0019] Before the present invention was adopted, the hammer of the coal crusher was worn due to long-term use, and the coal crushing effect was relatively p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com