PCCP pipeline rupture repair process

A pipeline and process technology, applied in the field of PCCP pipeline rupture repair technology, can solve the problems of large damage, waste of materials, difficult PCCP pipeline effective repair, etc., achieve uniform density, improve density and waterproof level, and ensure quality and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

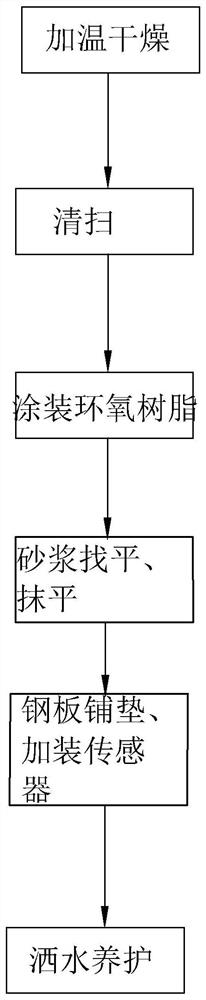

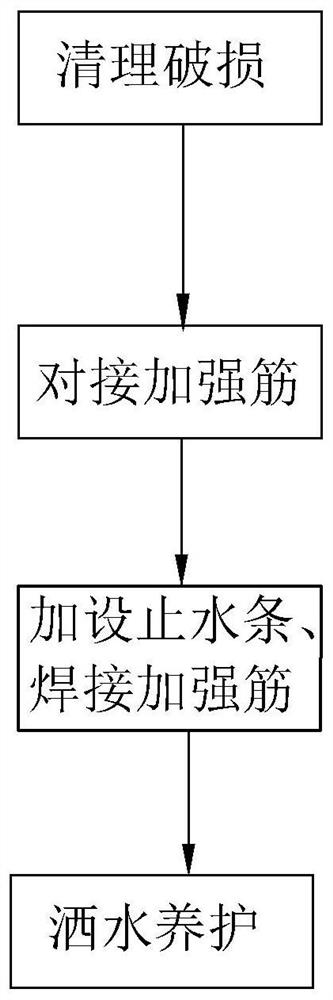

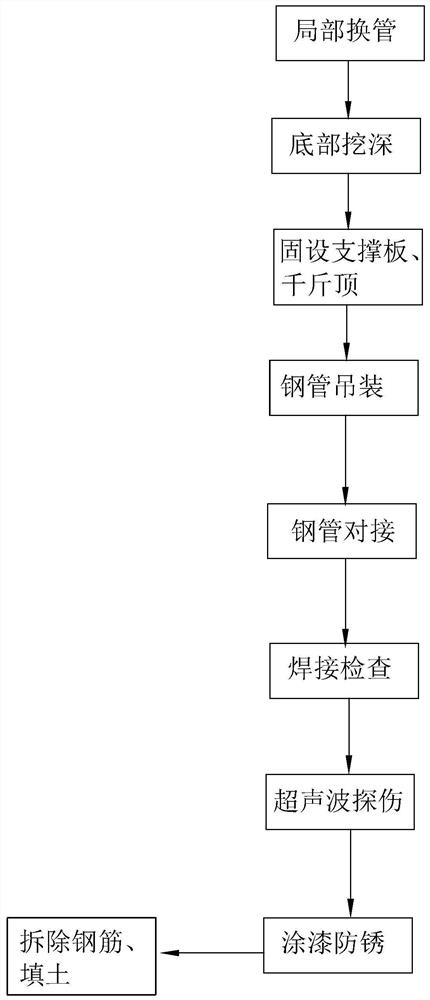

[0035] refer to figure 1 , is a PCCP pipeline rupture repair process disclosed in the present invention, which has three repair methods according to the degree of rupture, specifically as follows,

[0036] When a PCCP pipe breaks and is not leaking:

[0037] Step 1: heat and dry the damaged part of the drilled hole and its surroundings with a flame cutting tool to complete the inner surface of the hole formed by the damaged part of the drilled hole.

[0038] Step 2: Use a hard brush to clean the cracked part of the drilled hole, and dip the brush in water to moisten the crack.

[0039] Step 3: Apply the prepared epoxy resin evenly on the inner surface of the damaged hole to the outer edge.

[0040] Step 4: Use the configured epoxy mortar to level the cracked part, and brush the outer surface of the epoxy mortar repeatedly with a brush to smooth the mortar....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com