Magnetic absorption separated lifting camera

A magnetic adsorption and separation technology, applied in the direction of non-rotational vibration suppression, friction transmission, belt/chain/gear, etc., can solve the problem of poor stability and reliability of lifting cameras, limit the application and development of lifting cameras, transmission parts or guides Problems such as component breakage can be eliminated, and the process yield and mass production capacity are high, the structure is simple, and the service life is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

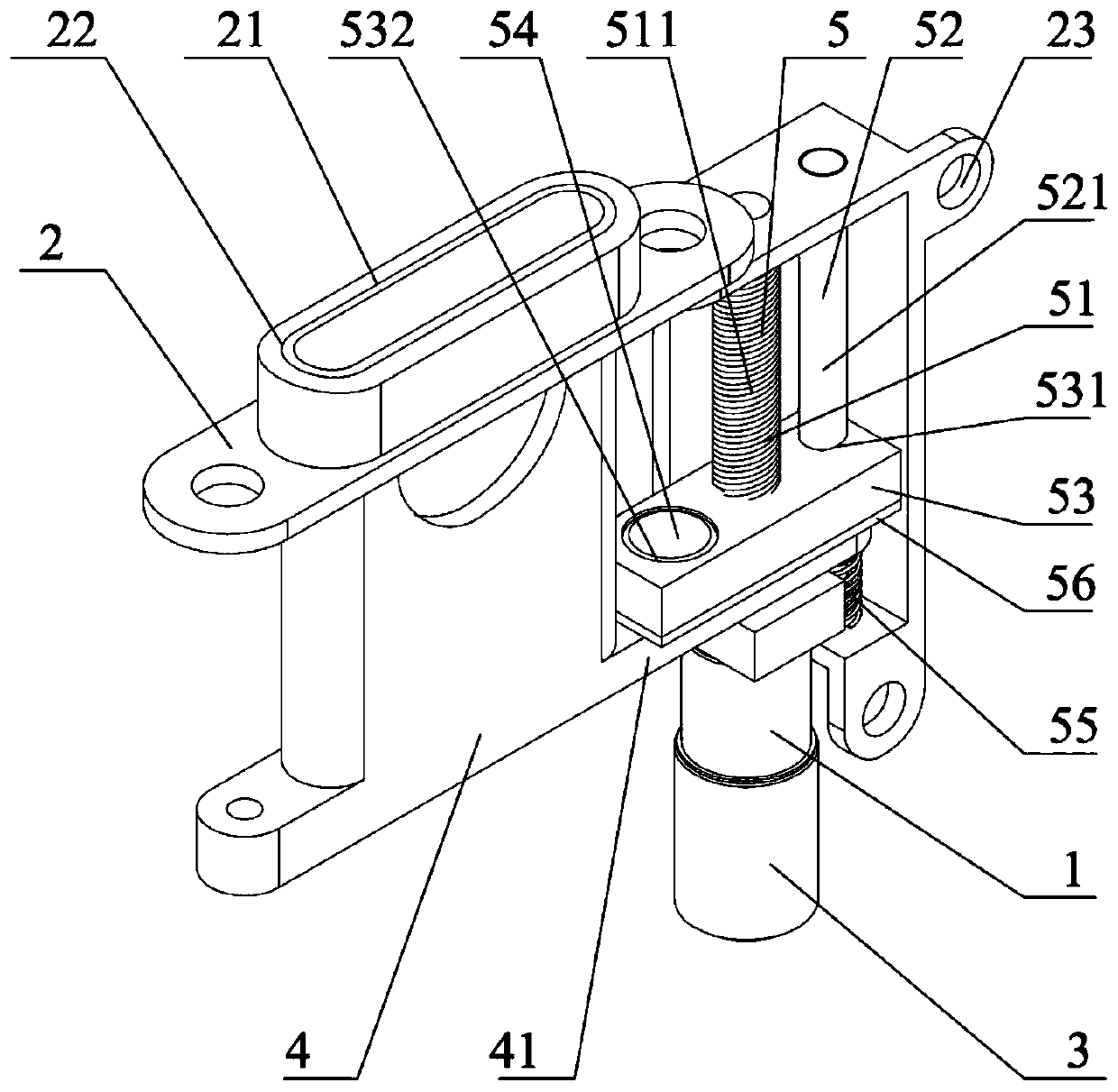

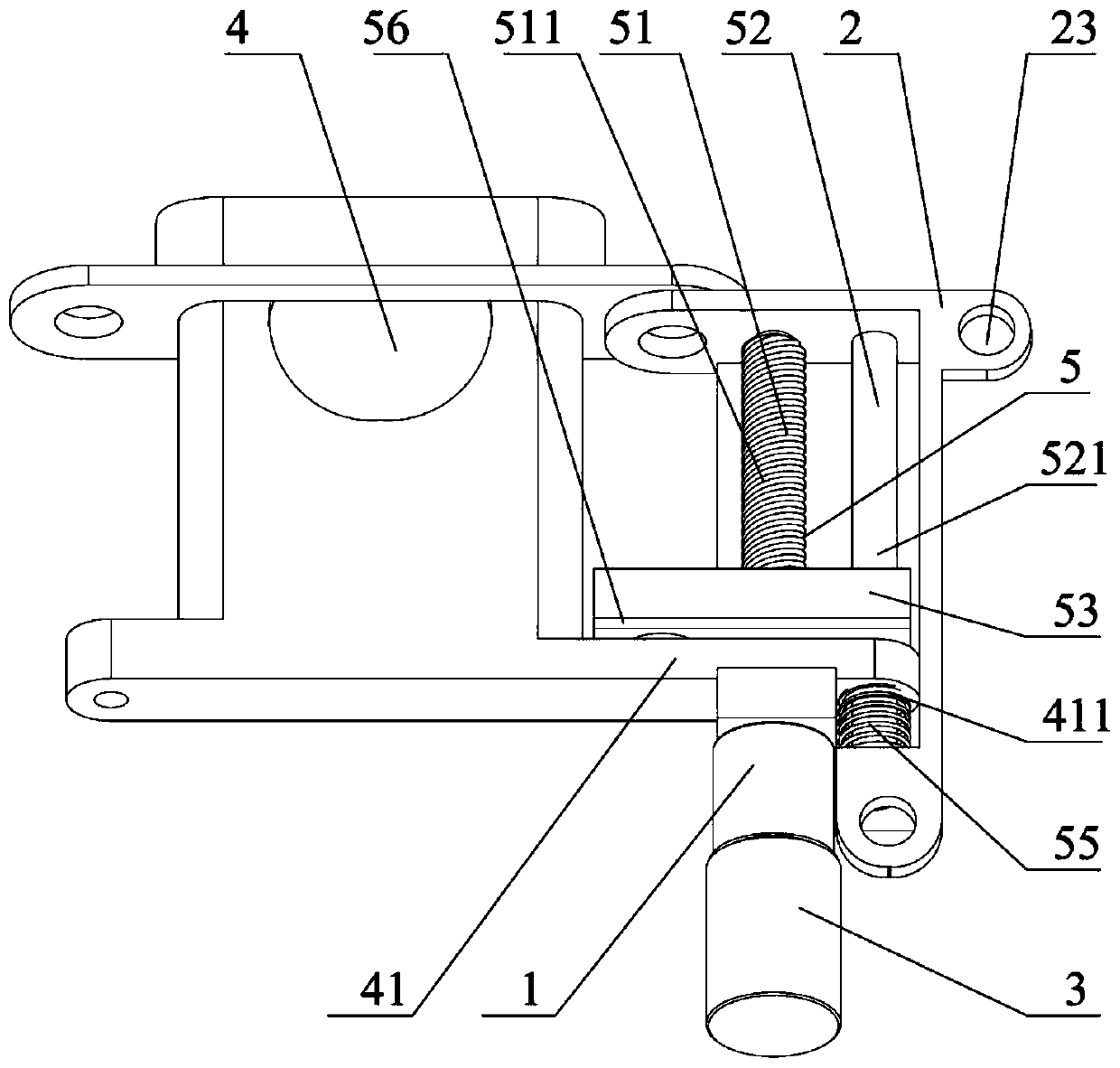

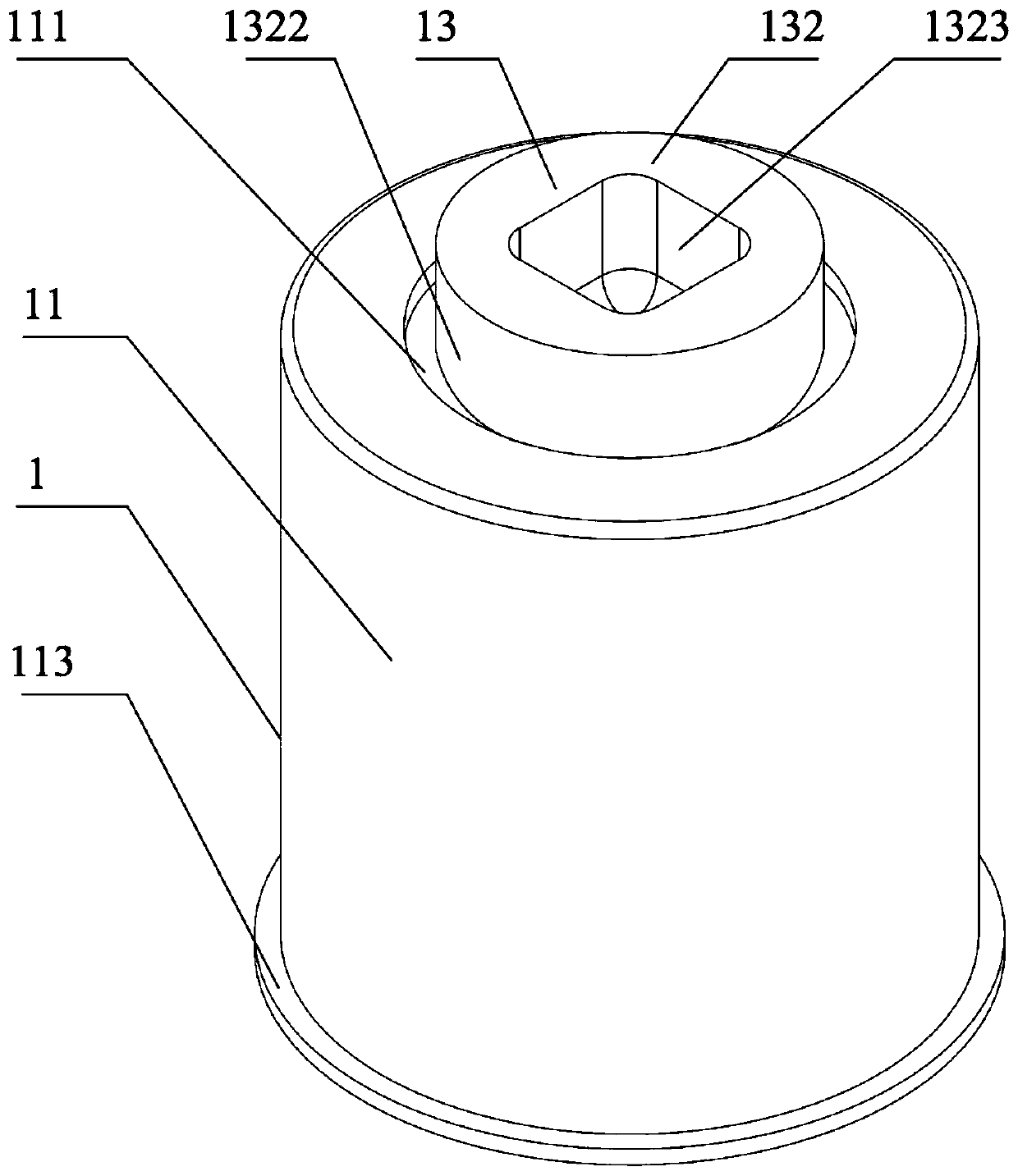

[0027] A magnetic adsorption detachable lifting camera, such as Figure 1~6 As shown, it includes a support frame 2 and a motor 3. The support frame 2 is provided with a camera module 4 and a lifting assembly 5 that drives the camera module 4 to lift. The moving block 53 and the guide mechanism 52 matched with the moving block 53, the camera module 4 has a first extension 41, the moving block 53 is magnetically attached to the first extension 41 through a permanent magnet 54, that is, the camera module 4 The first protruding part 41 and the moving block 53 can realize detachable connection, the first protruding part 41 is slidably connected with the guide mechanism 52, and the lower end of the guide mechanism 52 is provided with a first protruding part for separating from the moving block 53. The elastic element 55 matched with the part 41, the elastic element 55 is usually located at the initial position of the first protruding part 41, and the output end of the motor 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com