Steel wire mesh skeleton polyethylene composite pipe slow crack growth resistance test method

A polyethylene composite pipe, slow crack resistance technology, applied in the direction of analysis materials, test sample preparation, sampling, etc., can solve the problems of deformation and displacement, unmeasurable sinking pipe body, adjustment, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific details in the description of the present invention are only for fully understanding the embodiments of the present invention, but those skilled in the art should know that the implementation of the present invention is not limited to these details. In addition, well-known structures and functions are not described or shown in detail to avoid obscuring the gist of the embodiments of the present invention. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

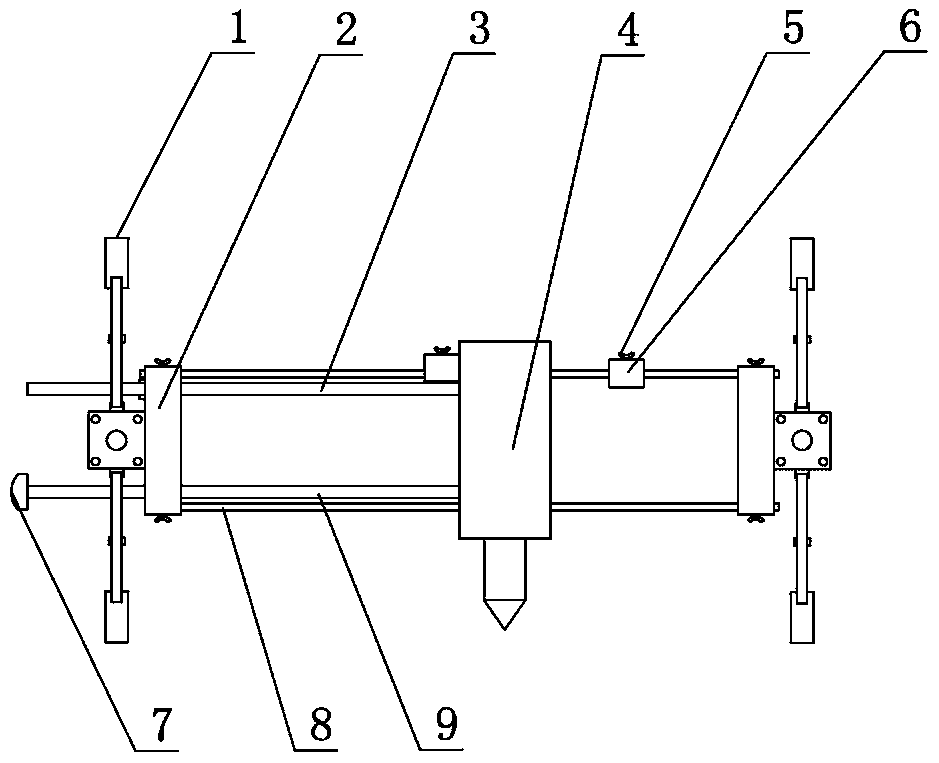

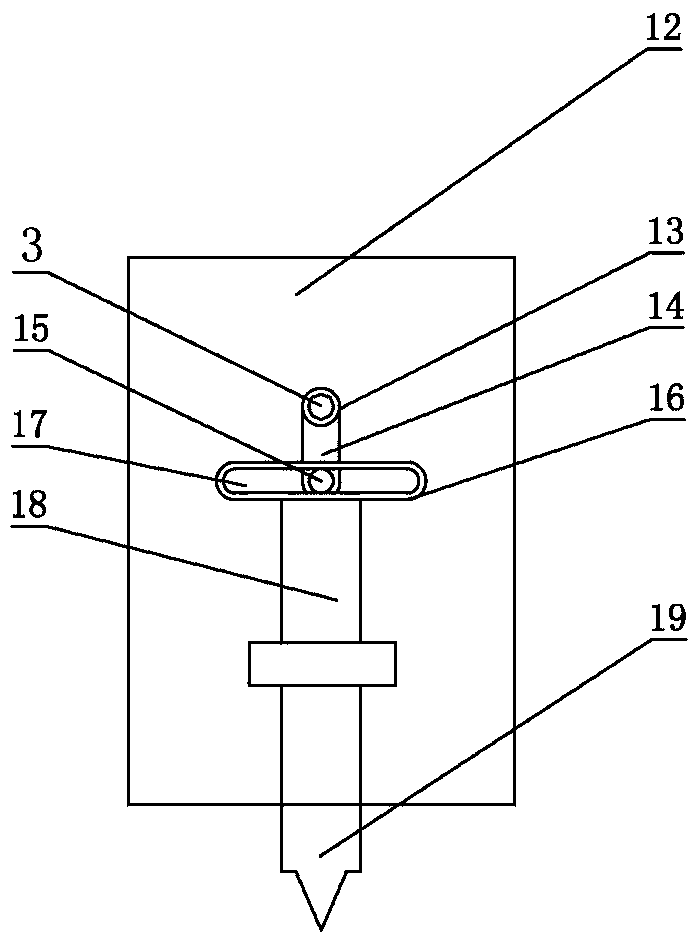

[0052] Specific implementation of the present invention: the specific steps of the described inner layer resistance to point load crack growth test are as follows:

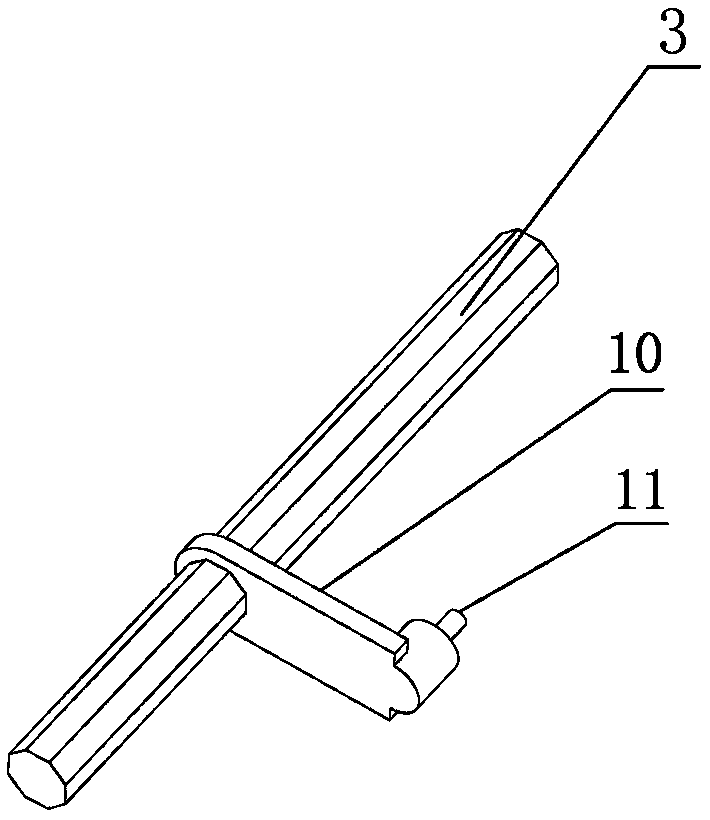

[0053] (1) Using special tools for making cuts in the inner layer of composite pipes to simulate cracks by machining cuts on the surface of the inner layer of the pipe;

[0054] 1. According to the actual length of the polyethylene composite pipe, adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com