Glass bottle surface spraying protection friction experiment device

An experimental device and surface spraying technology, which can be used in measurement devices, mechanical devices, instruments, etc., can solve problems such as lack of reference, and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

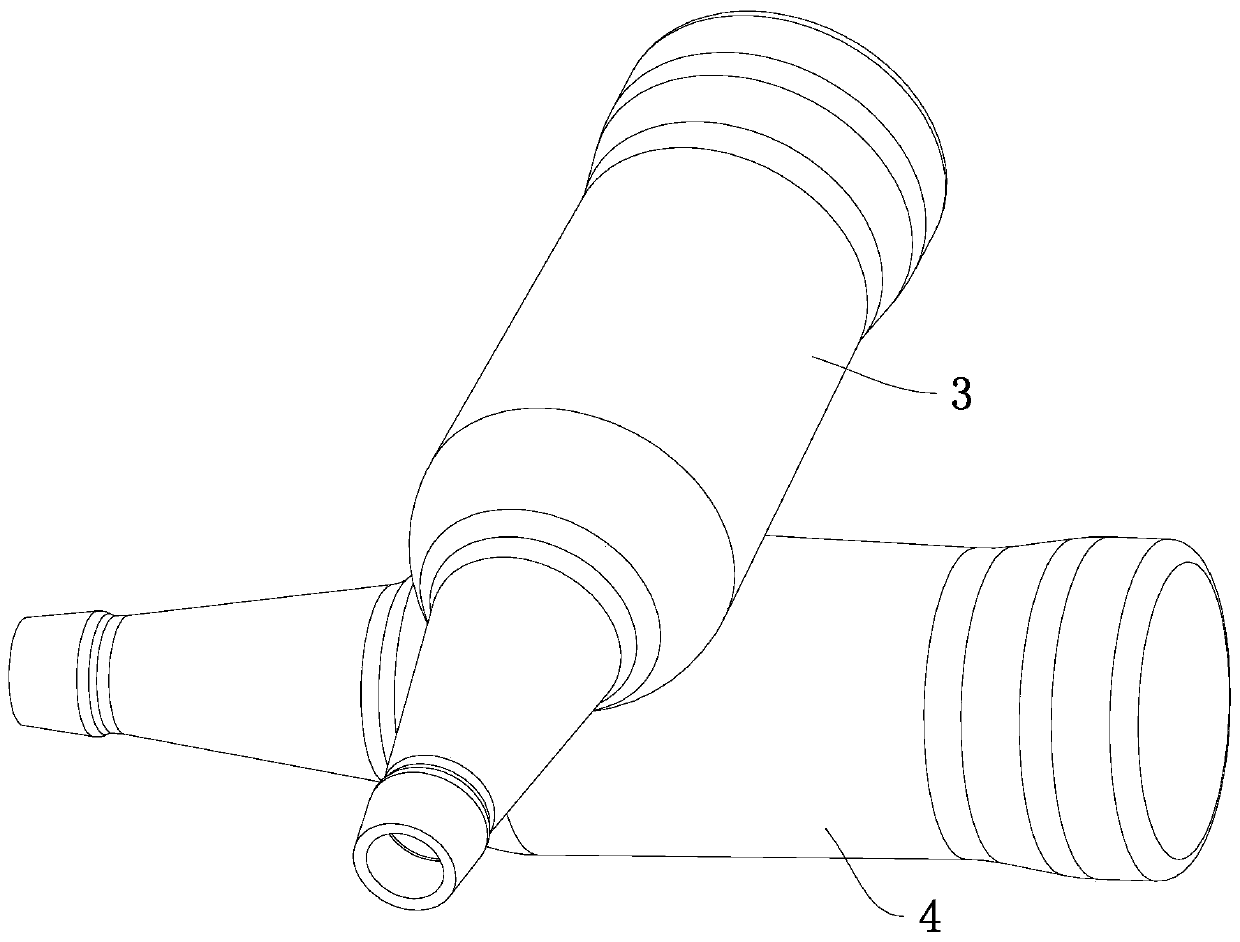

[0036] Example 1: An experimental device for spraying protective friction on the surface of a glass bottle, such as figure 2 As shown, in the actual production and transportation process, glass bottles will come into contact with each other, and there will be relative friction between the spraying on the surface. This friction is repetitive, and the angle between the glass bottles will change. The mutual friction movement will damage and fall off the organic coating on the surface of the glass bottle, which will damage the glass bottle and affect the use of the glass bottle. The test objects of this experimental device are the upper glass bottle 3 and the lower glass bottle 4.

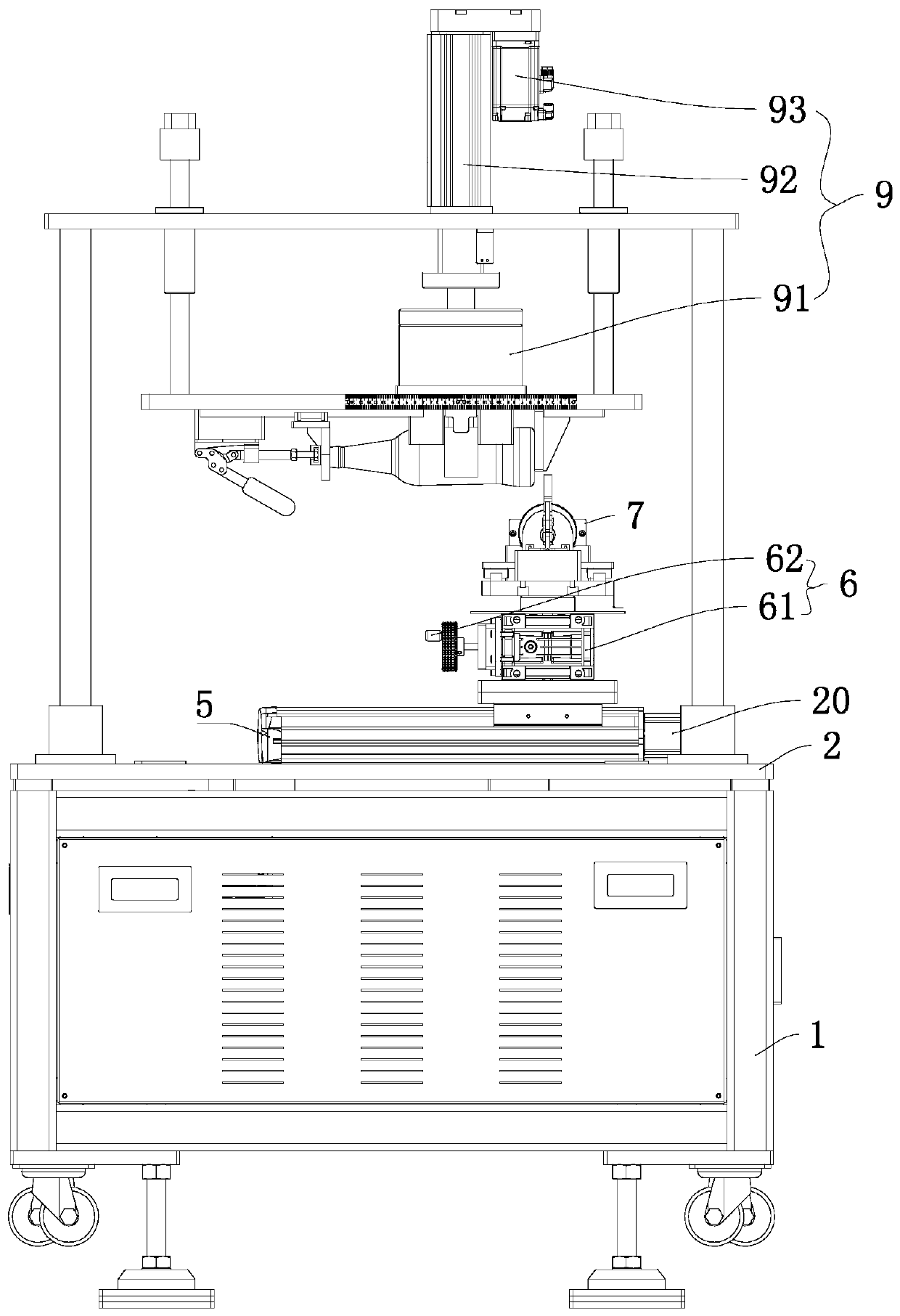

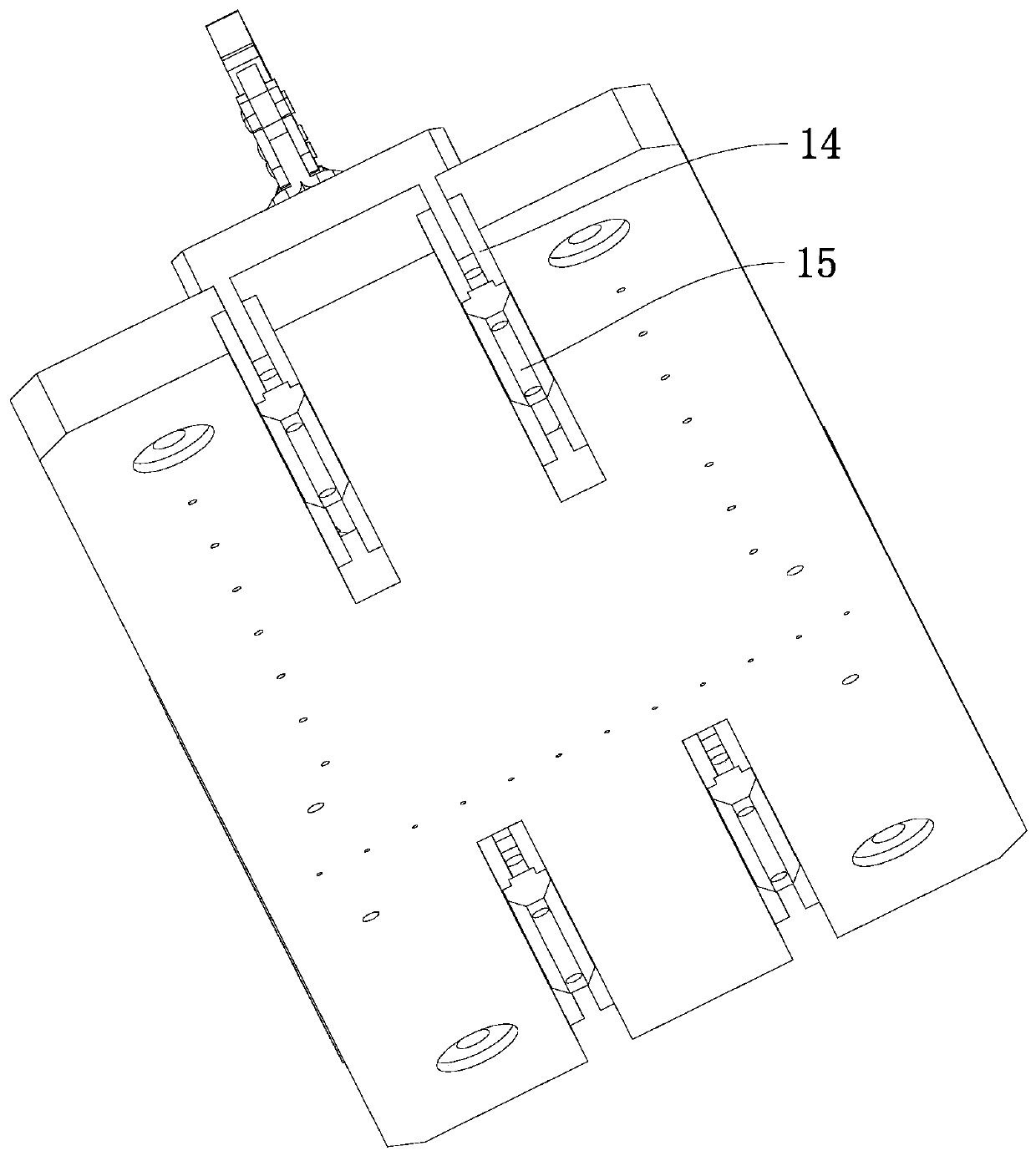

[0037] Such as figure 1 , Figure 5 and Image 6 As shown, the bottom of the experimental device is the frame frame 1, and the top of the frame frame 1 is fixedly connected to the workpiece platform 2. The top side of the workpiece platform 2 is installed with an electric actuator 5, and the servo motor 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com