A Method for Predicting the Performance of Lead Lap-Solder Interconnection Based on Electromagnetic Parameters of Physical Properties and Structure

A technology of electromagnetic parameters and lead lap welding, which is applied in the field of microwave interconnection, can solve problems such as spending more time, restricting the development of lead lap welding interconnection points, and being unable to give guidance on regulation and reference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The invention will be further described below with reference to the accompanying drawings and examples.

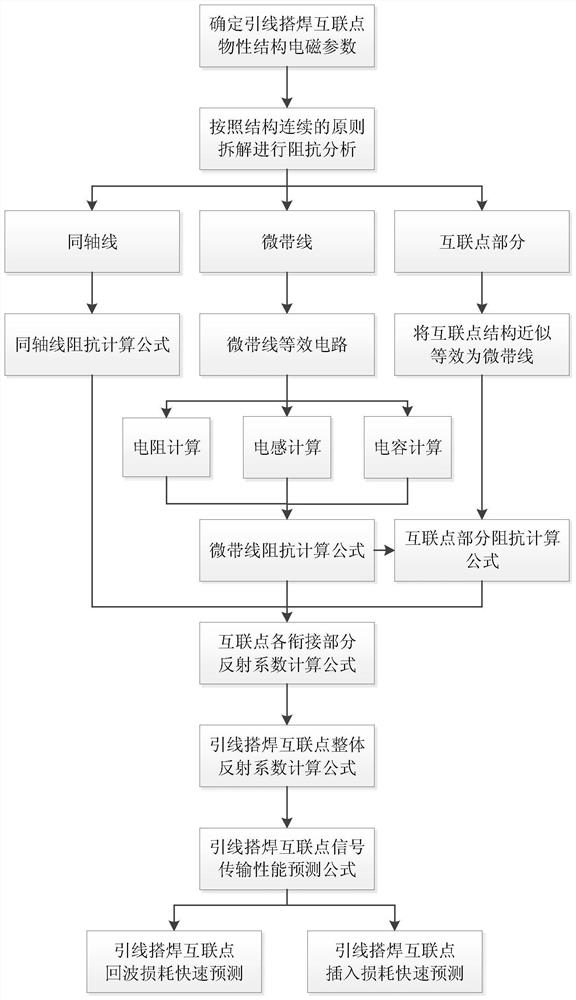

[0045] Refer figure 1 , The present invention is a lead-to-welding interopementary performance prediction method based on a physical structure electromagnetic parameter. The specific steps are as follows:

[0046] Step 1, determine the physical parameters of the lead pads, structural parameters.

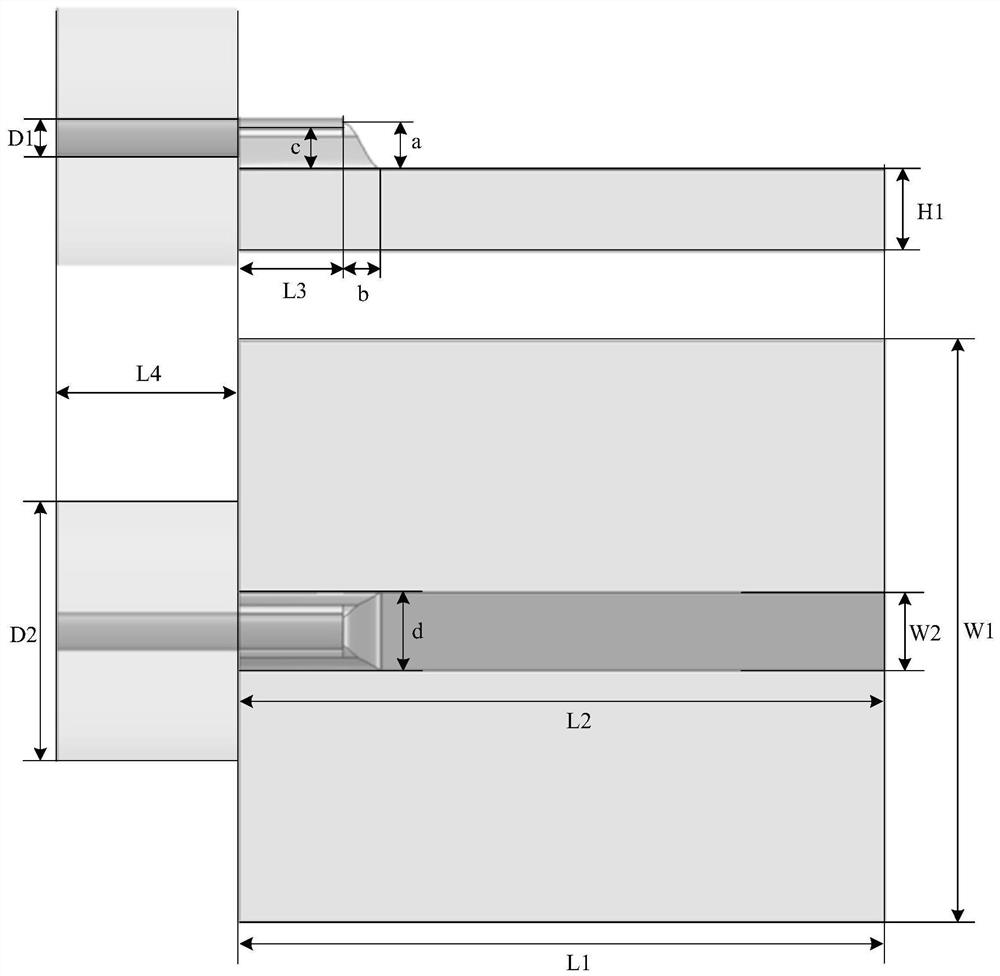

[0047]Lead-padded interoperability parameters such as figure 2 As shown, the relative dielectric constant of each part of the materials, relative conductivity, relative magnetic permeability and loss angle, etc., structural parameters include coaxial, interconnected points, dielectric substrate, microstrip line length, height, width, Diameter and spacing, etc., the electromagnetic operating parameters of the lead pads interoperability include the electromagnetic operating frequency f of the lead pad welding interopement.

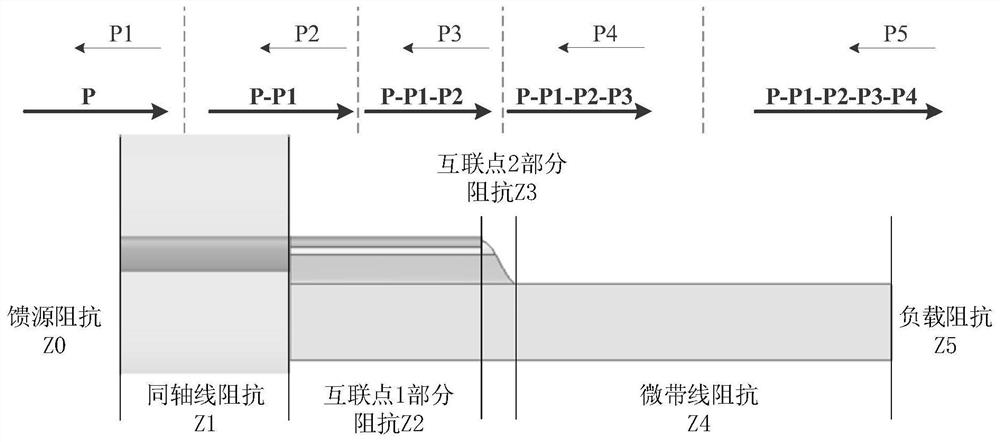

[0048] Step 2, the lead pad welding interconnection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com