Evaluation method for stability and result integrity of multi-batch process in batch charging (fragrance) mode

A complete and stable technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

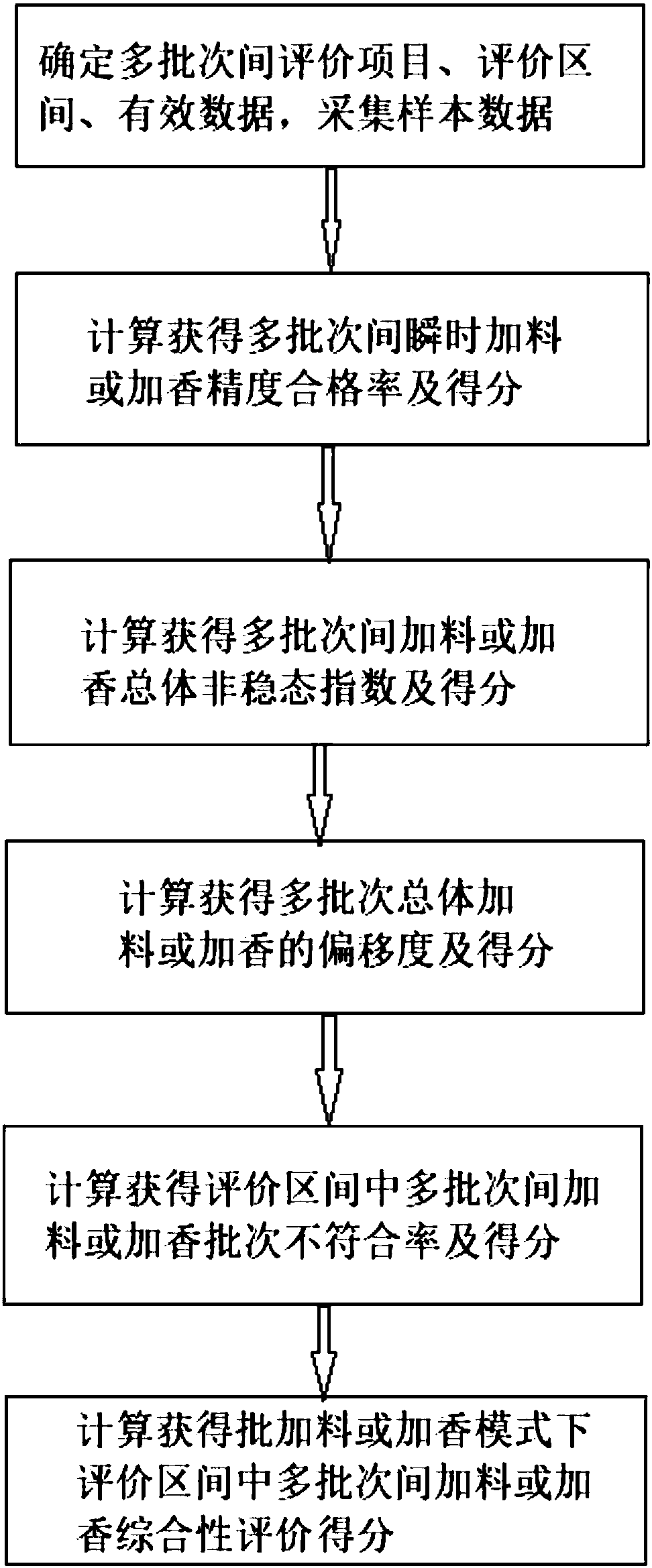

[0018] Using the feeding (fragrance) process stability and result integrity evaluation method of the silk production process under the batch feeding (fragrance) mode of the present invention may further comprise the steps:

[0019] Step 1. Determine the evaluation items between multiple batches; determine the evaluation interval; determine valid data; collect sample data.

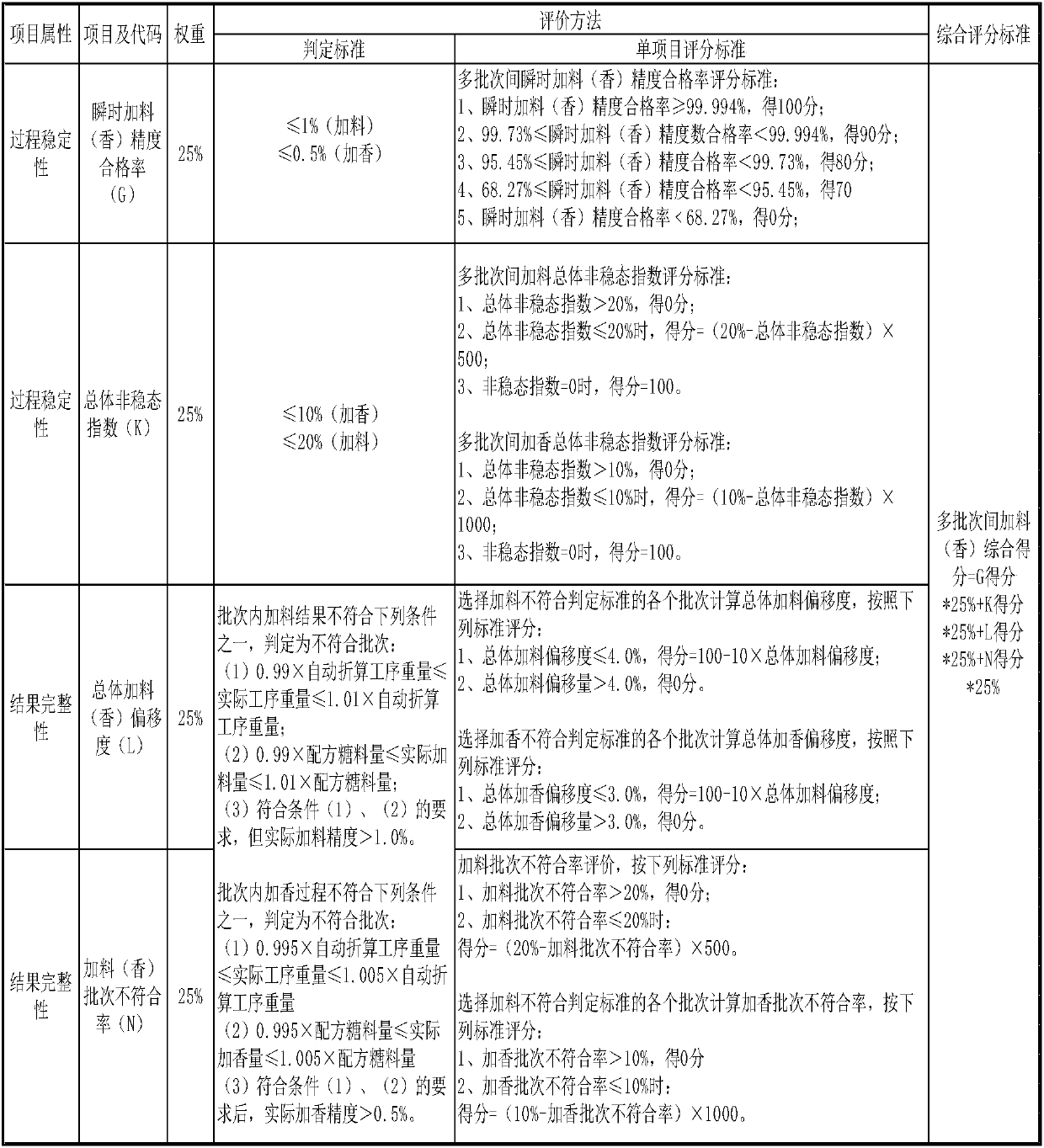

[0020] The evaluation items are based on the "Cigarette Process Specification" (2016 Edition) of the tobacco industry, and on the basis of referring to the industry standard "Guidelines for Data Acquisition and Processing of Cigarette Shredded Process" (YC / Z 502-2014), combined with batch feeding (flavor ) needs to be set for model quality evaluation. Determine the multi-batch evaluation items include: multi-batch instantaneous feeding or flavoring accuracy pass rate, multi-batch feeding or flavoring overall unsteady index, multi-batch overall feeding or flavoring deviation, multi-batch Batch-to-batch non-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com