Pasture harvest smashing and baling/harvest smashing, baling and coating combination machine

A technology of balers and shredders, which is applied to harvesters, balers, cutters, etc., can solve problems such as inability to continuously produce, low degree of automation, and a large number of human assistance, achieve automation and improve work efficiency, reduce manpower, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

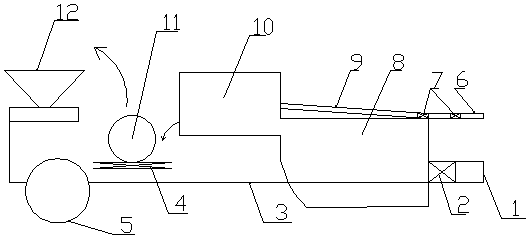

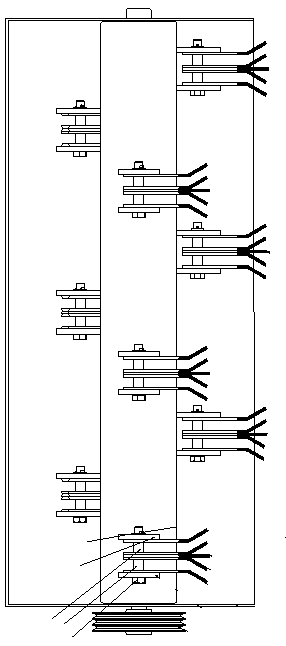

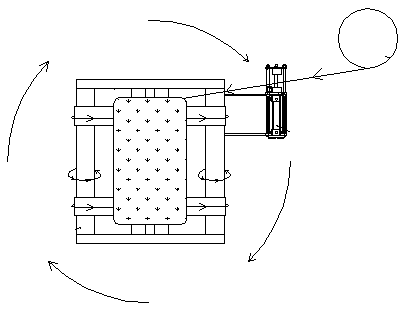

[0020] Design 1: Grass harvesting, crushing and bundling combined machine, including pasture harvesting and crushing machine 8, pasture baler 10, the rear body of the tractor is movably connected to the front end 1 of a support frame, and a pair of Supporting the walking wheels 5, on the supporting frame, a forage harvesting grinder 8 and a pasture bundling machine 10 are arranged successively from front to back, wherein the power input shafts of the pasture harvesting grinder and the bundling machine are respectively connected by universal joints 2 The rear power take-off shaft of the tractor, the two are linked.

[0021] Design 2: Another combination machine provided is a combination machine for pasture harvesting, crushing, bundling and filming, including a pasture harvesting and pulverizer 8, a pasture baler 10, a pasture bale wrapping machine 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com