High-efficiency flanging machine device for producing and manufacturing shoes

A high-efficiency, edge-folding machine technology, applied in the field of edge-folding machines, can solve the problems of reducing production capacity, increasing product production costs, affecting the flatness and aesthetics of footwear processing materials, and achieving the goal of improving utilization and improving layering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described with reference to the accompanying drawings.

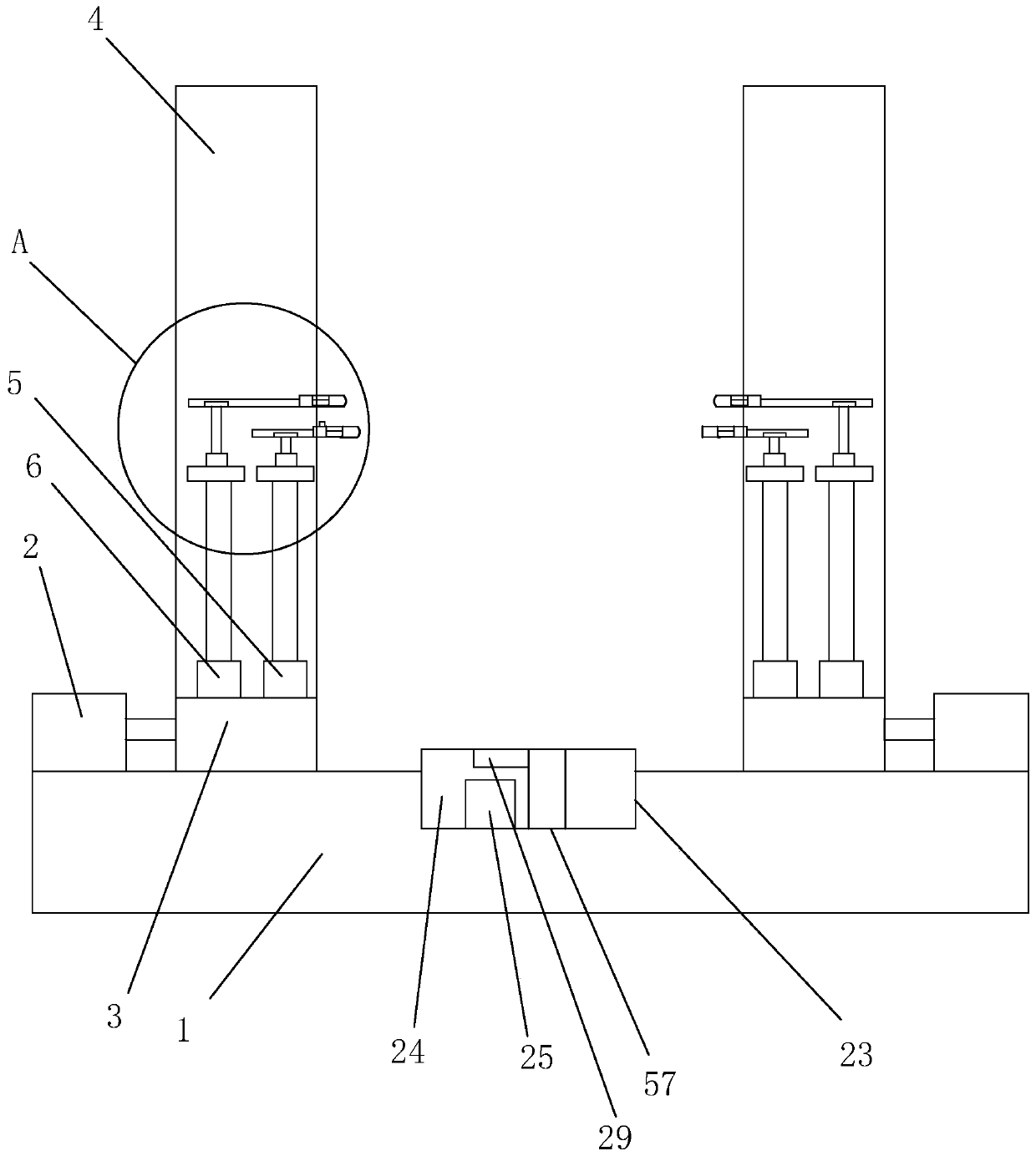

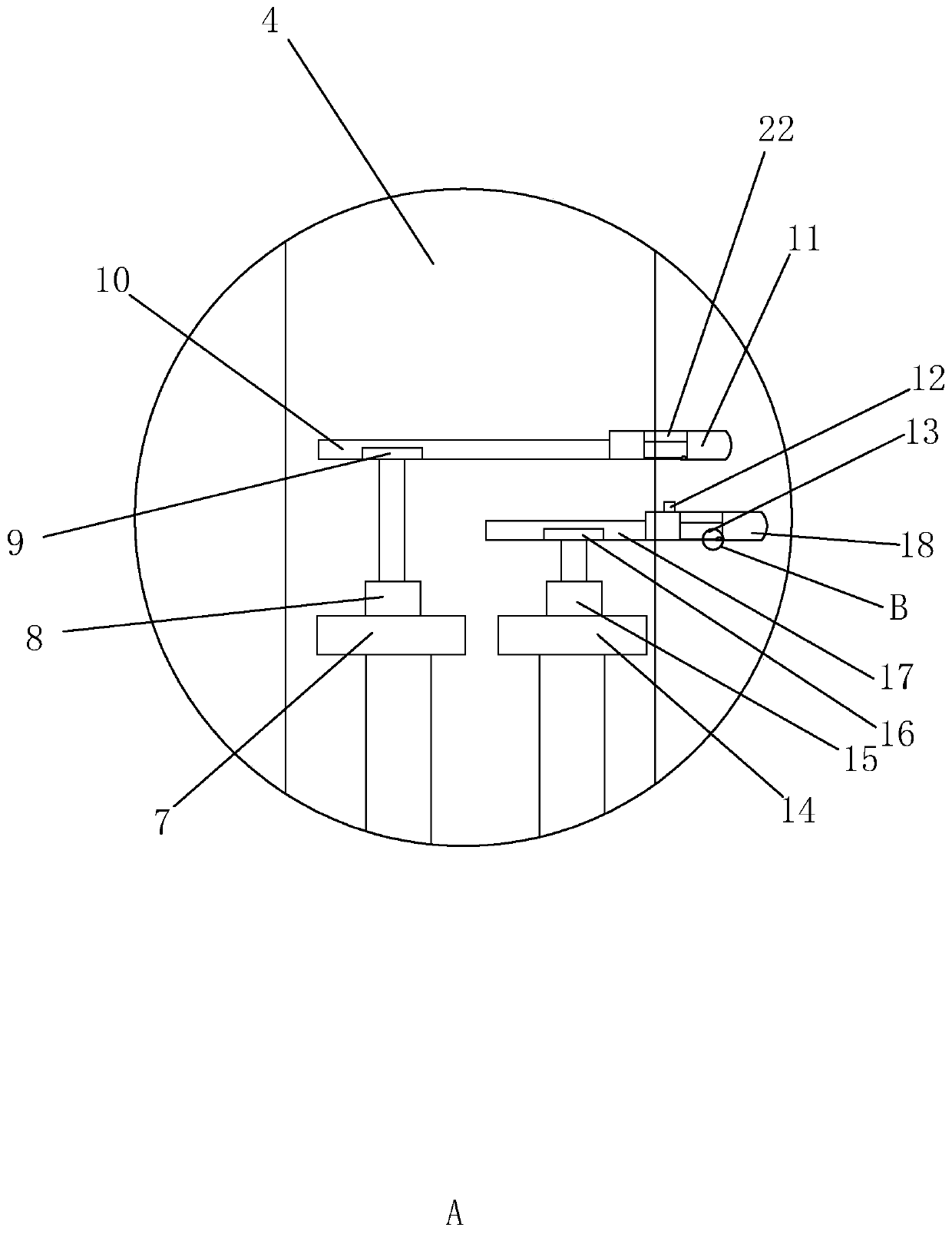

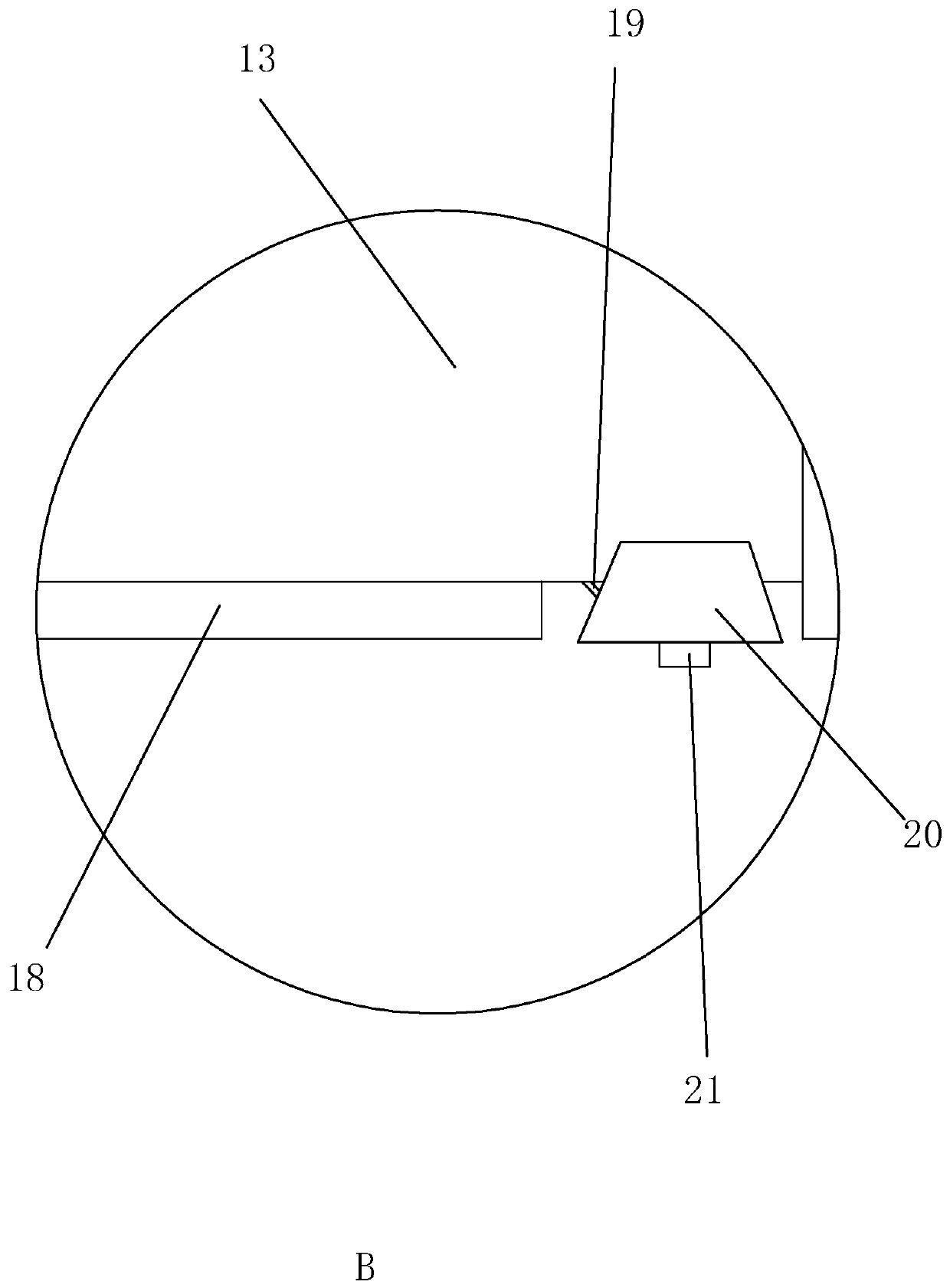

[0029] A high-efficiency folding machine device for footwear production, Figure 1-Figure 10As shown, it includes an underframe 1, the two sides of the underframe 1 are fixedly connected with horizontal cylinders 2 respectively, the horizontal cylinder 2 is connected with a push plate 3, and the push plate 3 is fixedly connected with a vertical plate 4. The bottom of the vertical plate 4 is respectively provided with a first lifting cylinder 5 and a second lifting cylinder 6, the first lifting cylinder 5 and the second lifting cylinder 6 are not in the same vertical plane, and the first lifting cylinder 5 is connected with a first Lifting plate 7, the first lifting plate 7 is provided with a first driving motor 8, the output shaft of the first driving motor 8 is sleeved with a first driving gear 9, and the first driving gear 9 is meshed with a first The gear bar 10, the first...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap