Cutting insert and cutting tool with adjustable structure

A technology of cutting tools and cutting inserts, which is applied to tools used in lathes, accessories of toolholders, turning equipment, etc., which can solve the problems that the adjustment mechanism cannot provide pre-tightening force, lose the adjustment of the cutting angle, etc., and achieve the radial direction of the insert. Large adjustment range, uniform distribution of cutting force, and improved overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

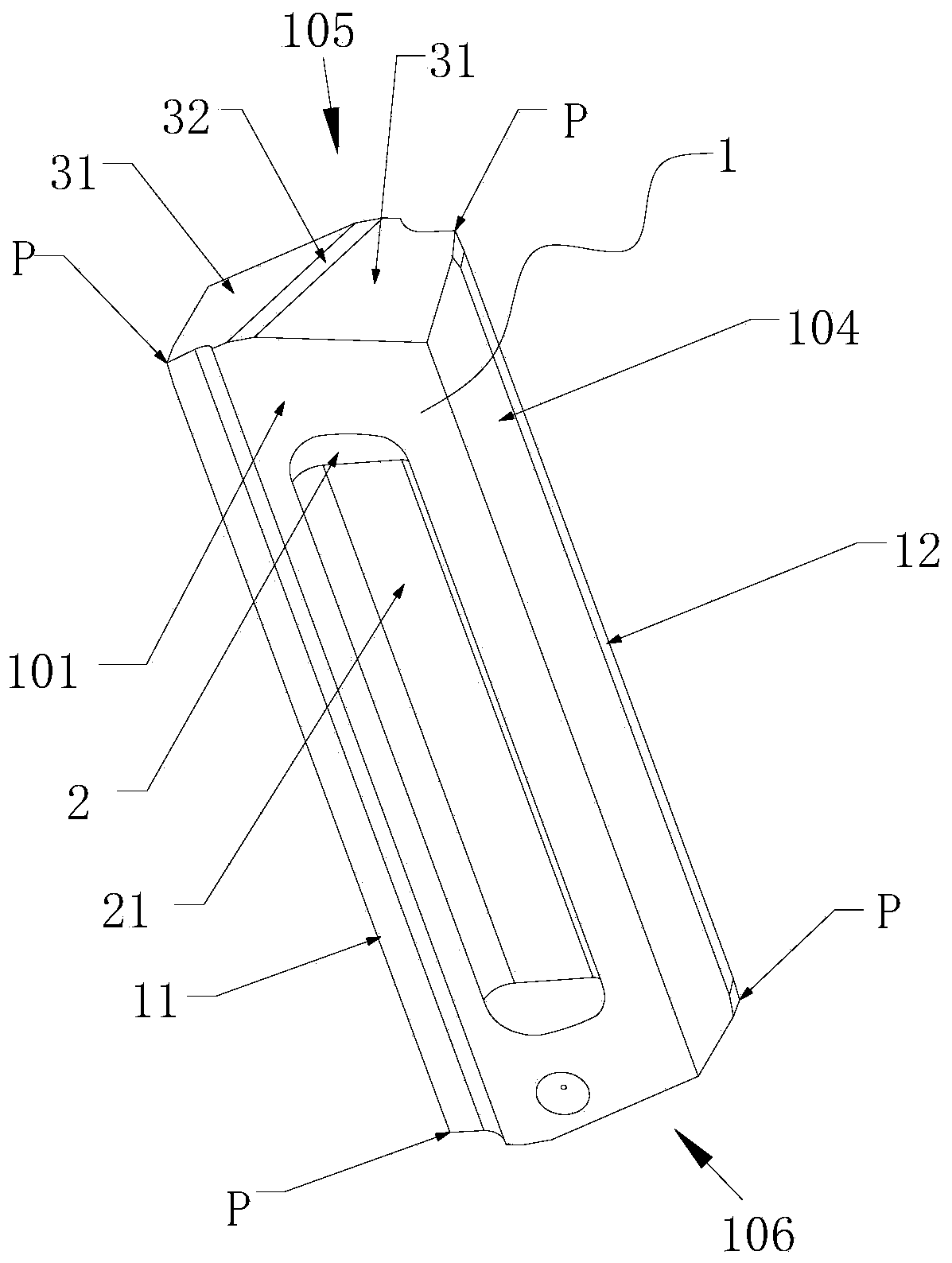

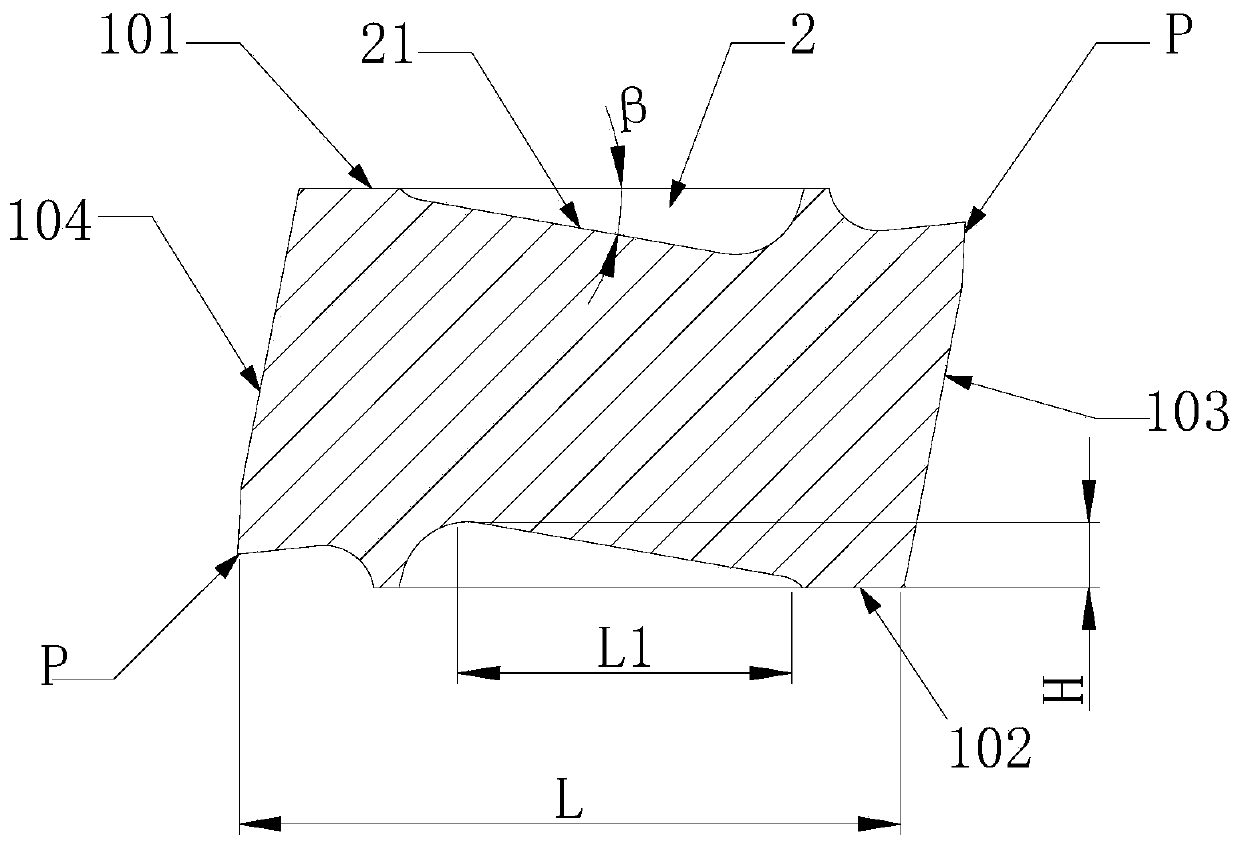

[0034] Such as figure 1 with figure 2 As shown, the cutting insert of this embodiment, the cutting insert 1 includes an upper end face 101, a lower end face 102, a first side 103, a second side 104, a third side 105 and a fourth side 106, the upper end 101 and the first side 103 The first cutting edge 11 is formed by intersecting, the second cutting edge 12 is formed between the lower end surface 102 and the second side surface 104, the second side surface 104 is located on the opposite side of the first side surface 103, and the upper end surface 101 is provided with a clamping groove 2, clamping There is a clamping slope 21 in the holding groove 2, and the angle between the clamping slope 21 and the upper end surface 101 is β, and β is an acute angle. In the direction from the second side 104 to the first side 103, the clamping slope 21 and the upper The distance H between the end faces 101 increases gradually, the first cutting edge 11 is center-symmetric about the second...

Embodiment 2

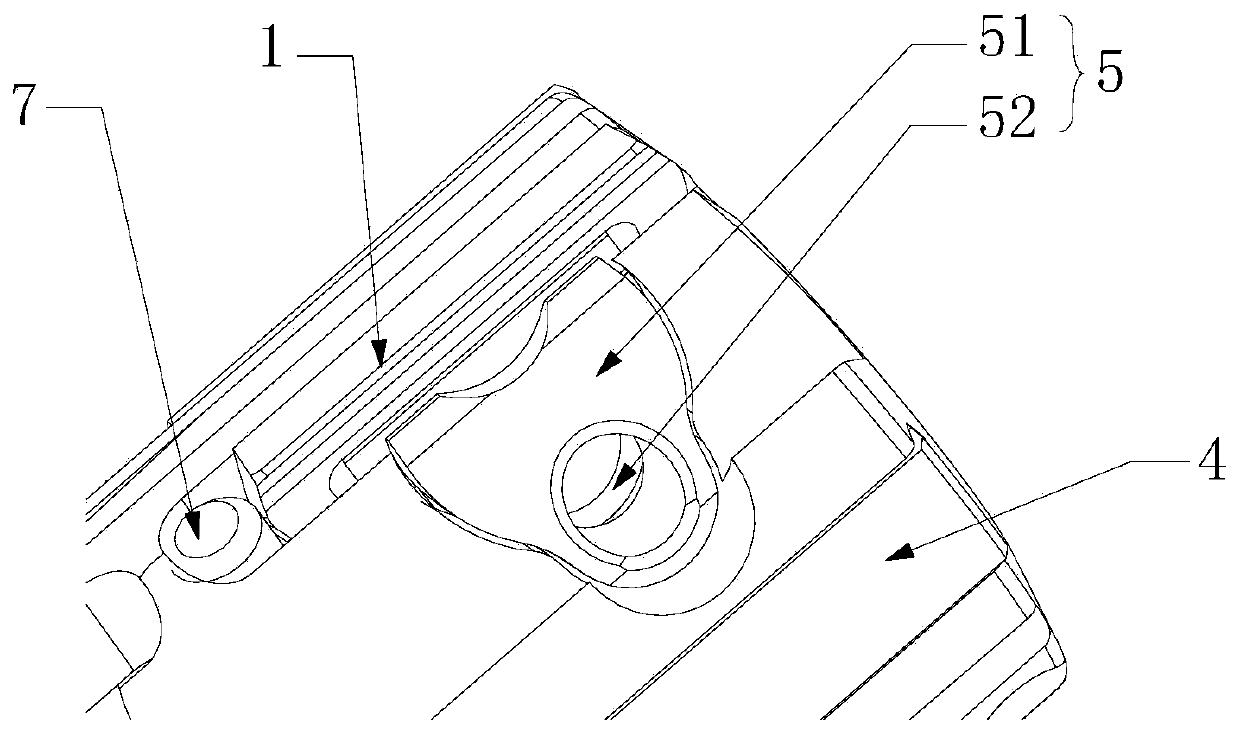

[0041] Such as Figures 3 to 7 As shown, the cutting tool with adjustable structure in this embodiment includes a cutter body 4, a blade pressing device 5 and a blade radial adjustment device 6, and the cutting tool also includes the cutting blade 1 of the above-mentioned embodiment 1, and on the cutter body 4 A sipe 41 and an adjustment installation groove 42 communicating with the sipe 41 are provided. The cutting blade 1 is installed in the sipe 41 and pressed by the blade pressing device 5 . F4 is the reaction force of the sipe 41 to the blade. The first cutting edge 11 and the first side surface 103 face outwards, the blade pressing device 5 has a pressing surface 501 matched with the clamping inclined surface 21, and the blade radial adjustment device 6 is arranged in the adjustment installation groove 42 for pushing the cutting blade 1 moves radially in the sipe 41, and the angle between the axis of the blade radial adjustment device 6 and the horizontal plane is θ, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com