Disassembly-preventive sealing fast lunch box

A fast food box and lunch box technology, applied in the direction of sealing, locking equipment, closing, etc., can solve the problems of difficult stacking, food leakage, pollution, etc., and achieve the effect of convenient movement and transportation, preventing soup from flowing out, and reasonable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

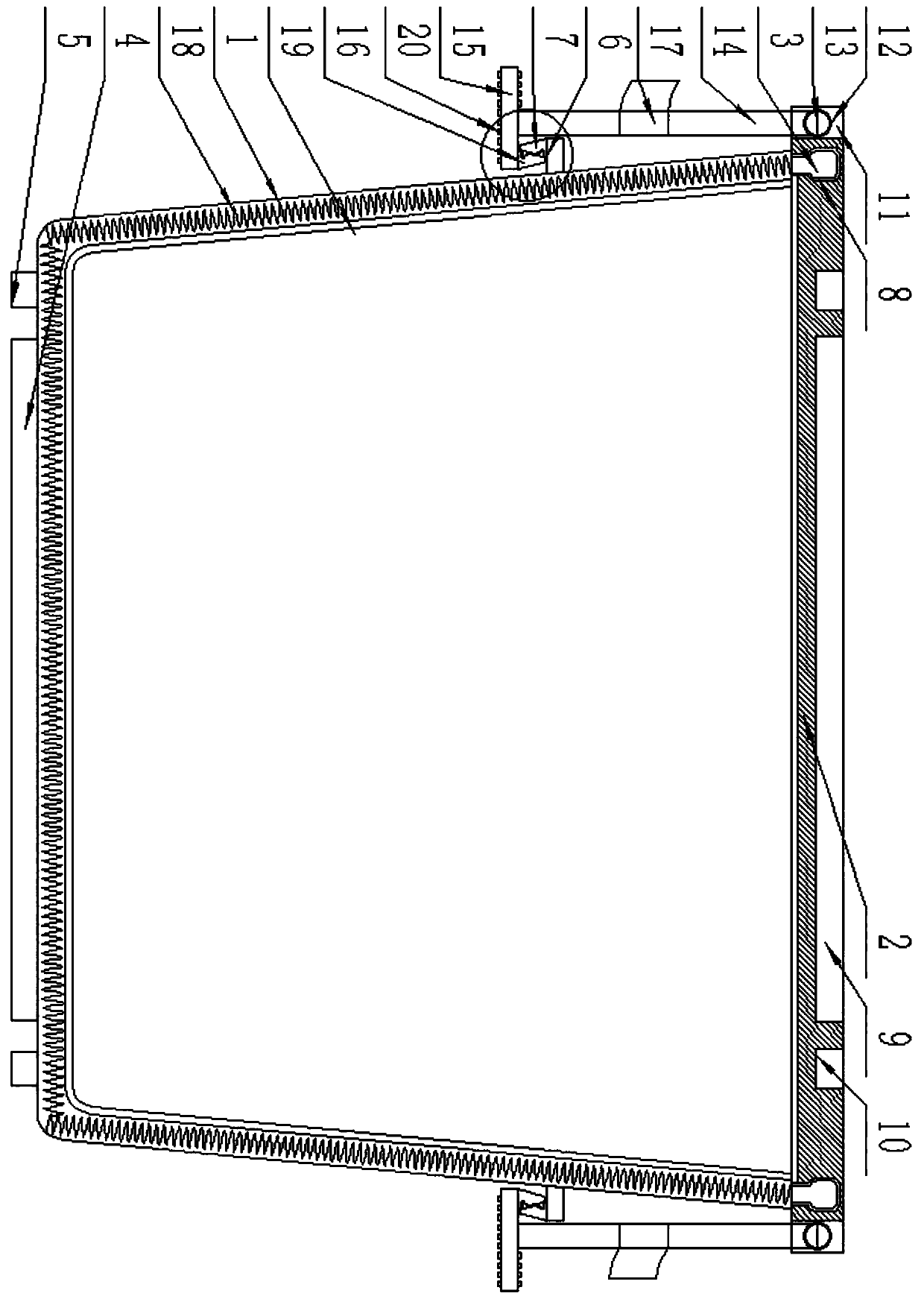

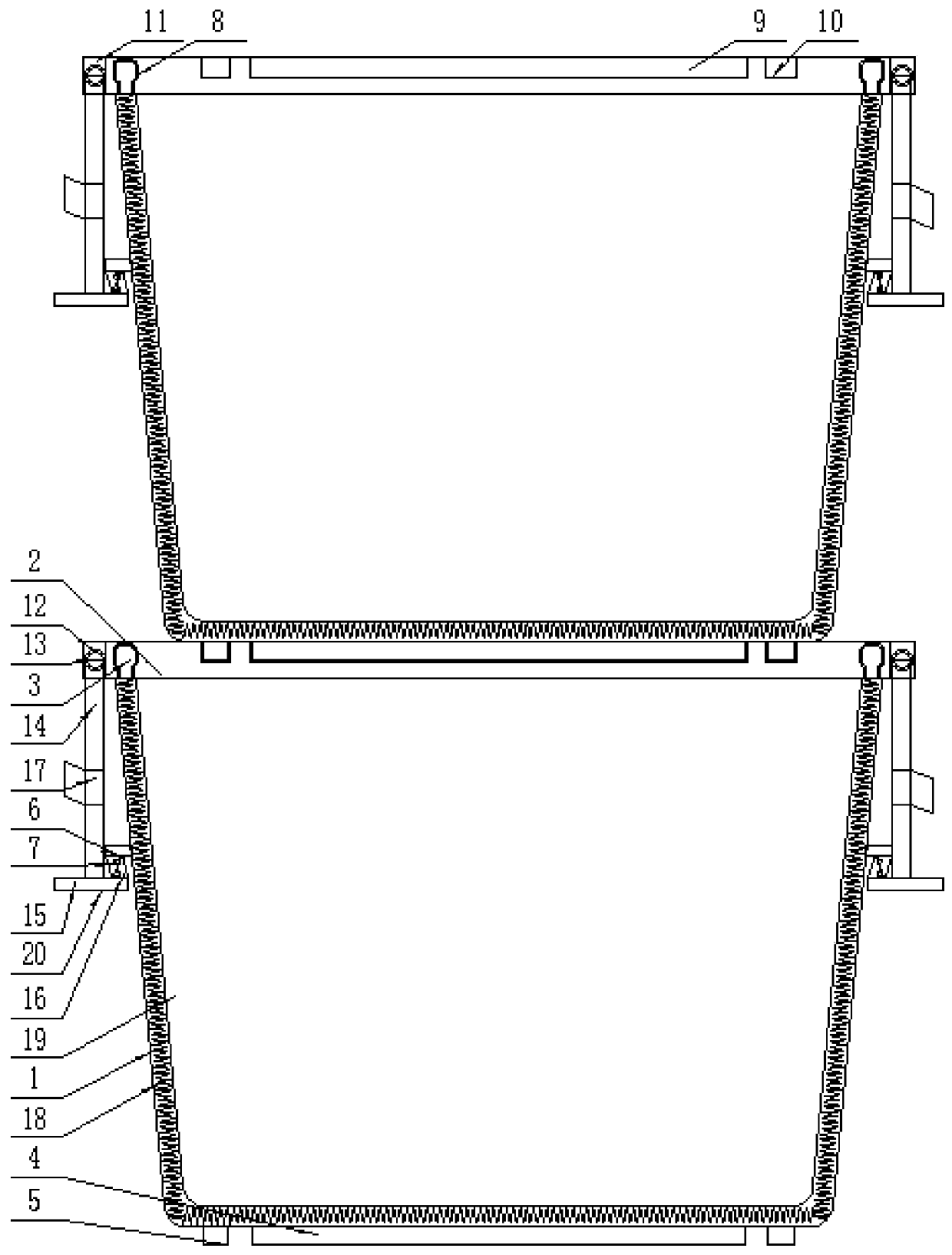

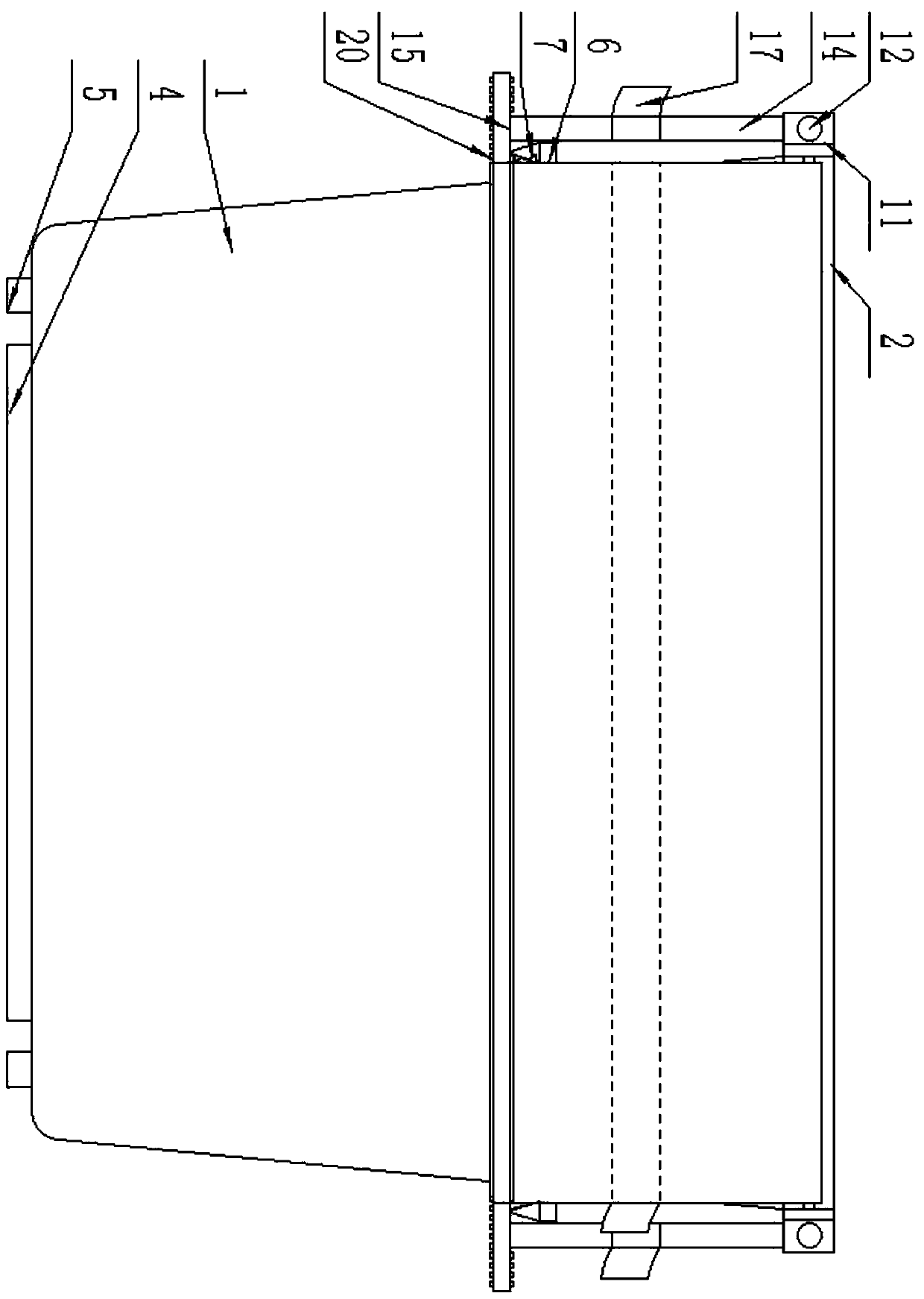

[0021] Such as Figure 1 to Figure 6 As shown, the specific embodiment adopts the following technical solutions: a kind of anti-disassembly type sealed fast food box, comprising a lunch box body 1 and a lid body 2, the top of the lunch box body 1 is provided with an annular sealing edge 3, and the lunch box body 1 is provided with an annular sealing edge 3, and the lunch box body 1 The center of the lower surface of the box body 1 is provided with a positioning block 4, and the lower surface of the lunch box body 1 is provided with an annular clamping block 5 outside the positioning block 4, and the outer surface of the lunch box body 1 is respectively provided with a clamping plate 6. The lower surface of the clamping plate 6 is respectively provided with a lower card edge 7, the edge of the lower surface of the lid body 2 is provided with an annular sealing groove 8 matching the annular sealing edge 3, and the center of the upper surface of the lid body 2 is provided with Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com