Propellant charge cannon shooting overload resistance test and evaluating method

A technology of propellant and charge, applied in jet propulsion device, rocket engine device, machine/engine, etc., can solve the problems of increasing product research and development workload and cost, low reliability, and unclear structural parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

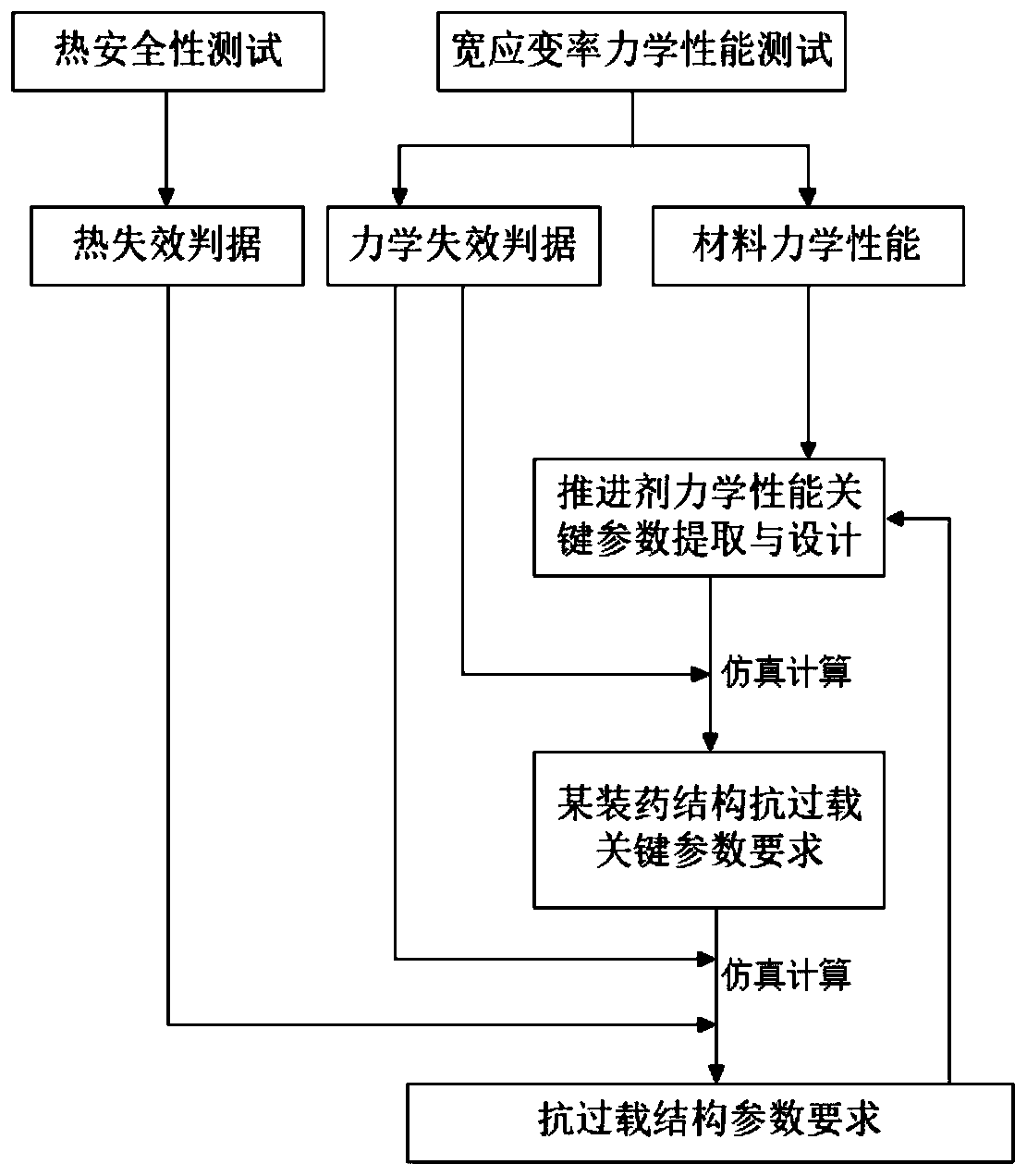

[0078] figure 1 It is the basic flowchart of the test and evaluation method of the present invention, and the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0079] according to figure 1 The basic process of the propellant charge of the present invention cannon shot overload test evaluation method, the specific implementation steps are as follows:

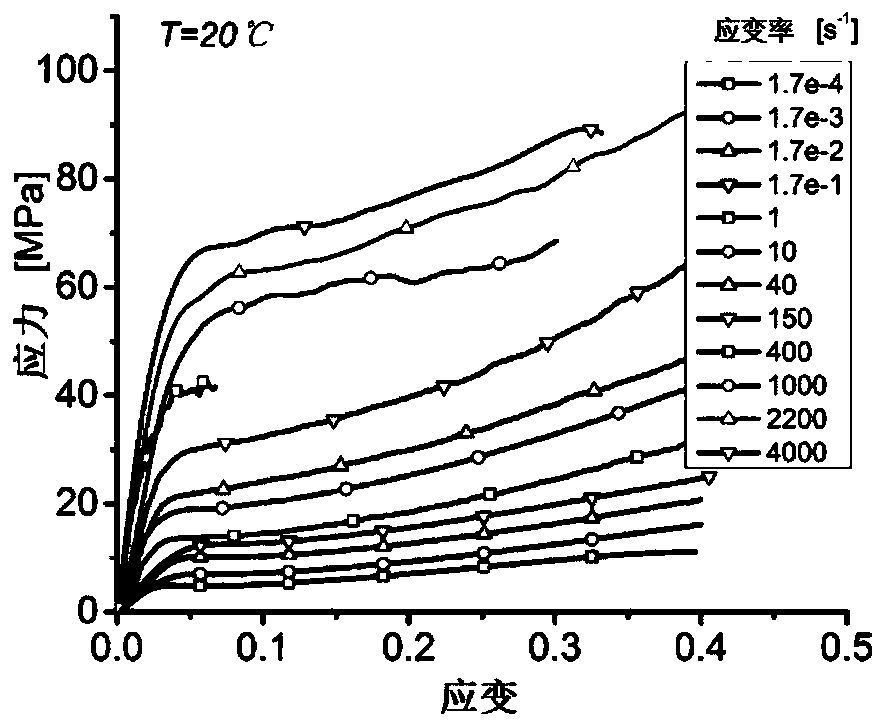

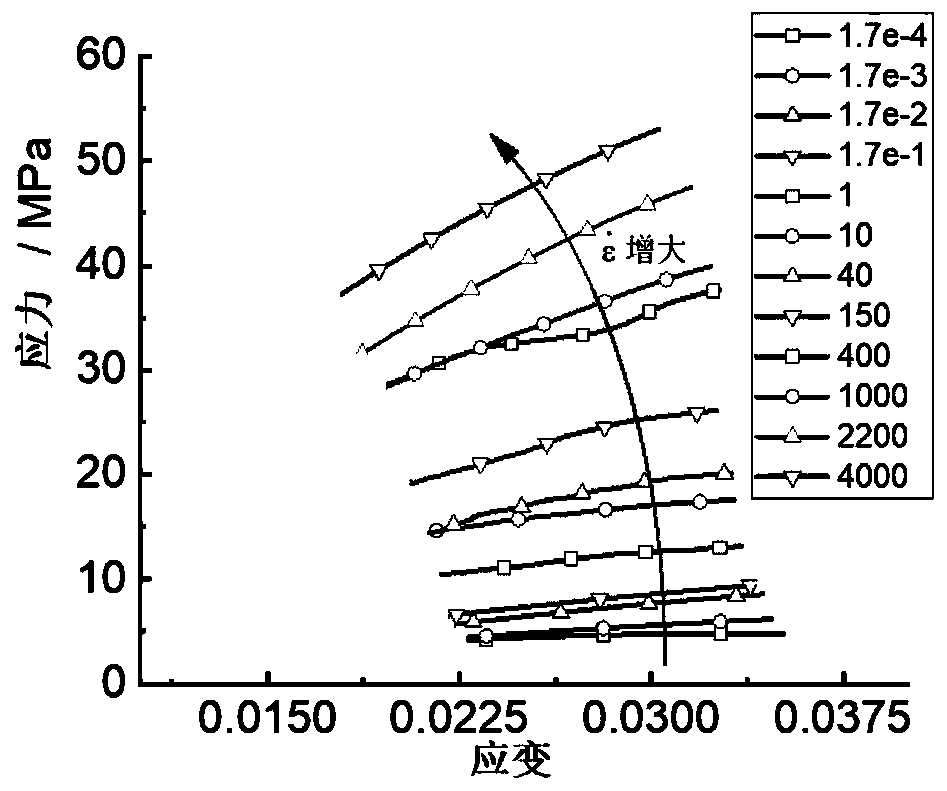

[0080] Step 1: A formula CMDB propellant and its typical tube charge structure (outer diameter D = 62mm, inner diameter d = 13mm, length L = 140mm) are given as the initial scheme, and the wide strain rate mechanical properties of the reformulated propellant are carried out testing and friction sensitivity testing.

[0081] The same batch of propellant billets used in the machining test was used. The dimensions of cylindrical specimens for low strain rate and medium strain rate tests are The dimensions of the cylindrical specimen for the high s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com