An anti-wear ring multi-point electric testing tool

An anti-wear ring, multi-point technology, applied in the field of anti-wear ring multi-point electrical detection tools, can solve the problems of easy mutual influence of indication values, and achieve the effect of reducing influence and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

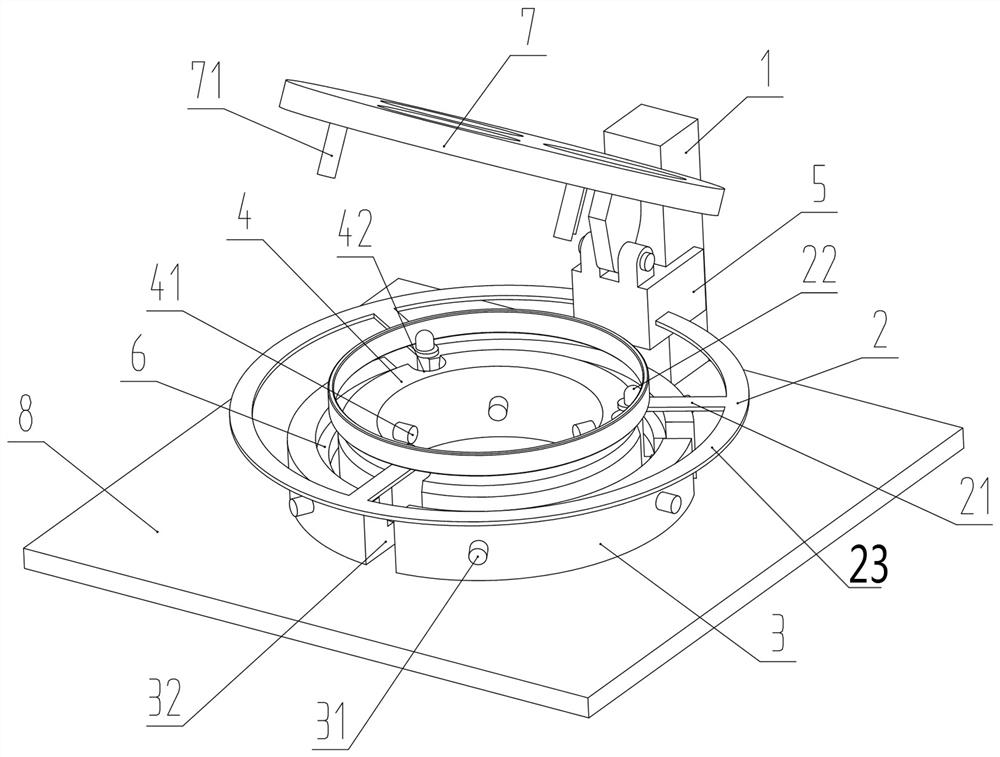

[0017] Such as figure 1 As shown, an anti-wear ring multi-point electric measuring tool includes a Z-guiding rail 1, a measuring bracket 2, an inner detection ring 4 and an outer measuring ring 3, the Z-guiding rail 1 is arranged vertically, and the Z A slider 5 is slidably connected to the guide rail 1, and the slider 5 is fixedly connected to the measuring bracket 2; the slider 5 is driven to move up and down by a lead screw, a motor or an air cylinder.

[0018] The outer measuring ring 3 is coaxially sleeved on the outer side of the inner detecting ring 4, and there is a gap between the two for the workpiece to enter; the inner detecting ring 4 is provided with a plurality of inner hole probes 41 along its circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com