Novel treadmill motor

A treadmill, a new type of technology, applied in the direction of electromechanical devices, control mechanical energy, sports accessories, etc., can solve the problems of increasing energy consumption, occupying a large space, and consuming motor energy, so as to improve work reliability, save installation space, The effect of eliminating assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

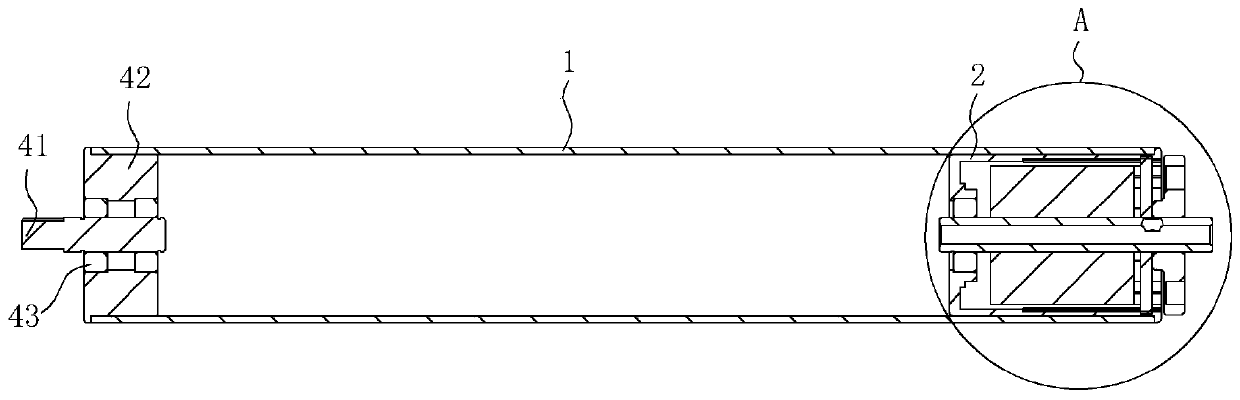

[0018] refer to figure 1 and figure 2 , a new type of treadmill motor in this embodiment includes a treadmill drum 1, a first outer rotor motor 2, an auxiliary shaft 41, a sealing block 42 and an auxiliary bearing 43.

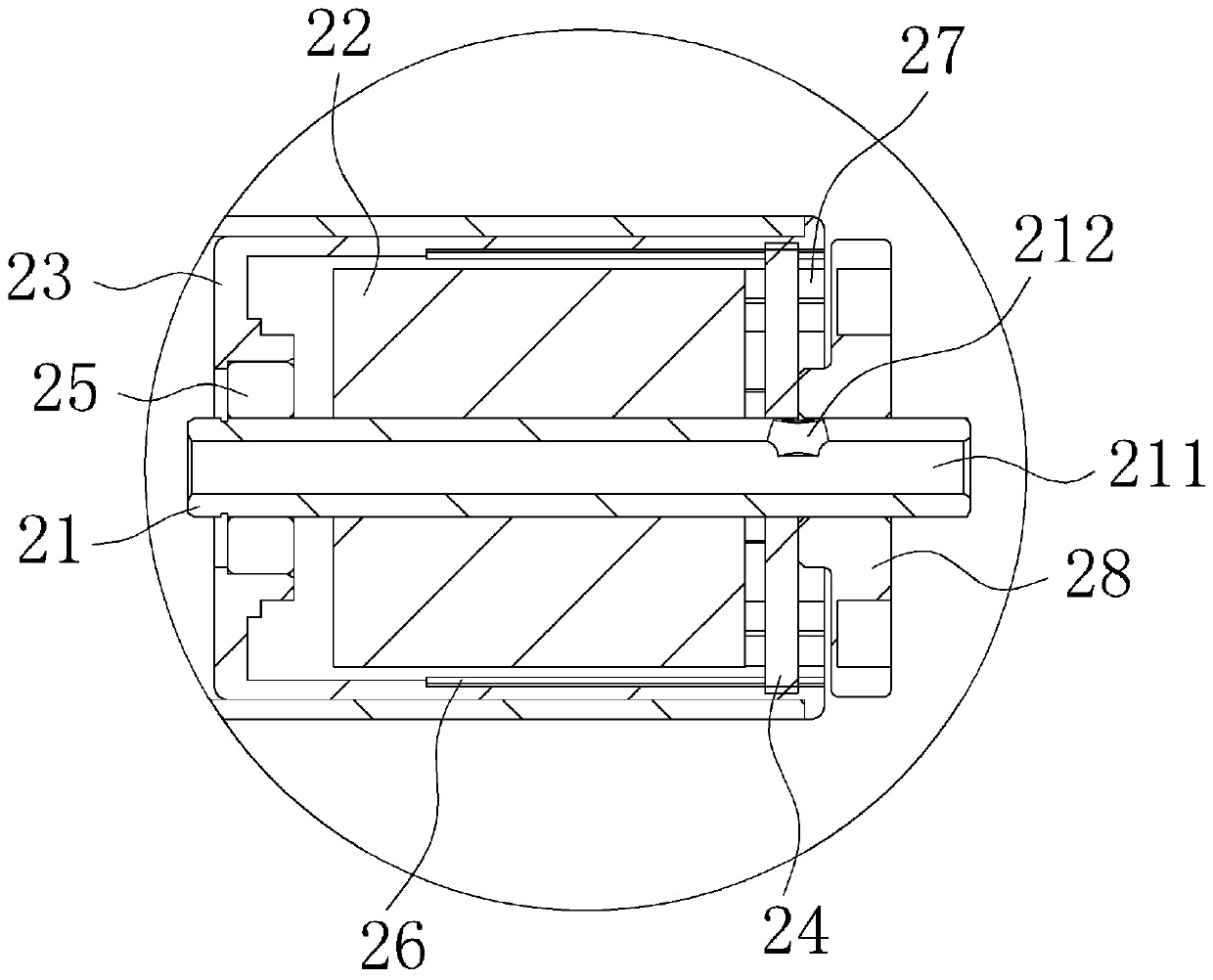

[0019] The first outer rotor motor 2 includes a first shaft 21, a first stator 22, a first outer rotor 23, a first drive plate 24, a first bearing 25, a first permanent magnet 26, a first sealing block 27 and a first cover plate 28. The first stator 22 and the first bearing 25 are respectively fixedly fitted on the first shaft 21, the first drive plate 24 is fixedly fitted on the first shaft 21, and the first outer rotor 23 is fitted on the first bearing 25, so that the first An outer rotor 23 can rotate on the first bearing 25, the first permanent magnet 26 is fixedly embedded in the first outer rotor 23, and the first permanent magnet 26 is opposite to the first stator 22, and the first stator 22 and The first driving board 24 is electrically connected by...

Embodiment 2

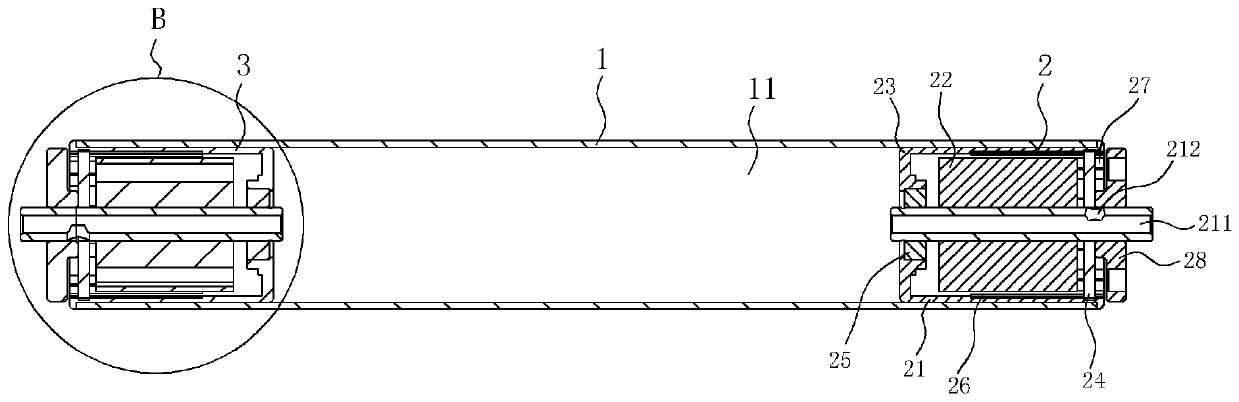

[0025] refer to image 3 and Figure 4 , a new type of treadmill motor in this embodiment includes a treadmill drum 1, a first outer rotor motor 2 and a second outer rotor motor 3.

[0026]The first outer rotor motor 2 includes a first shaft 21, a first stator 22, a first outer rotor 23, a first drive plate 24, a first bearing 25, a first permanent magnet 26, a first sealing block 27 and a first cover plate 28. The first stator 22 and the first bearing 25 are respectively fixedly fitted on the first shaft 21, the first drive plate 24 is fixedly fitted on the first shaft 21, and the first outer rotor 23 is fitted on the first bearing 25, so that the first An outer rotor 23 can rotate on the first bearing 25, the first permanent magnet 26 is fixedly embedded in the first outer rotor 23, and the first permanent magnet 26 is opposite to the first stator 22, and the first stator 22 and The first driving board 24 is electrically connected by wires, and the first driving board 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com