Aquaculture water inlet pipe filter screen cleaning device

A technology for aquaculture and water inlet pipes, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve problems such as sticky sludge, back pain, heavy workload, etc., to prevent self-moving and physical fatigue , the effect of preventing back pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

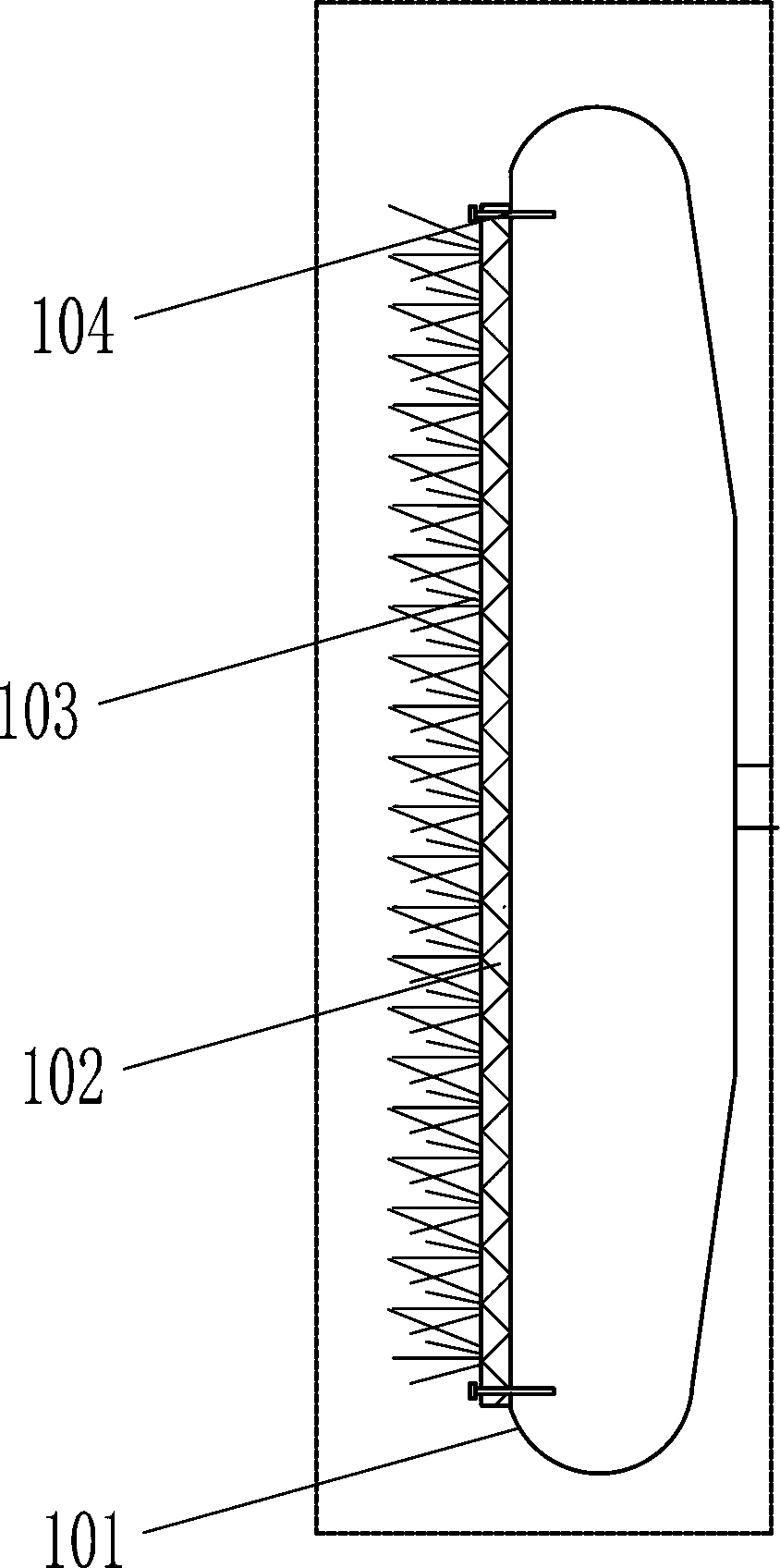

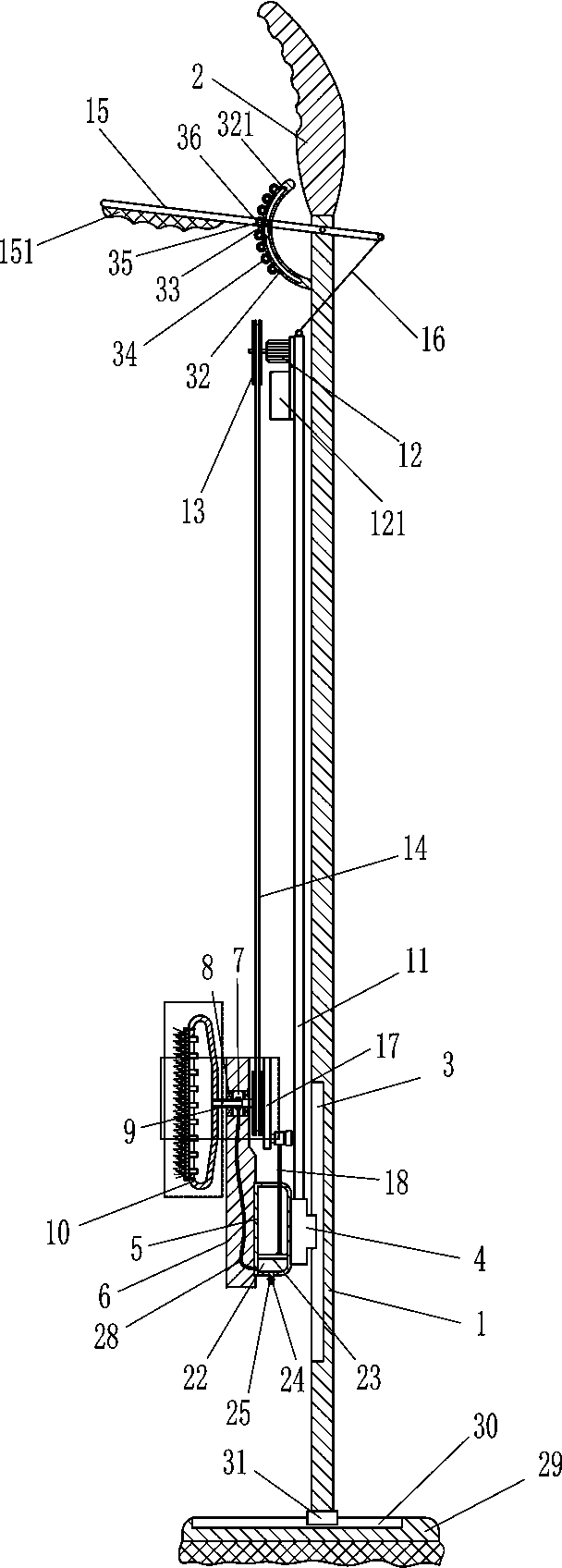

[0016] A kind of aquaculture inlet pipe strainer cleaner, such as Figure 1-2 As shown, it includes a pole 1, a handle 2, a straight slide rail 3, a straight slide block 4, a mounting block 5, a mounting plate 6, a deep groove ball bearing 8, a rotating shaft 9, a wiping device 10, a mounting rod 11, and a rotating motor 12 , power supply 121, pulley 13, flat belt 14, swing bar 15, grip 151 and stay cord 16, handle 2 is installed on the top of pole 1, pole 1 is connected with handle 2 by the mode of welding connection, pole 1 left The lower part of the side is embedded with a straight slide rail 3, and the straight slide rail 3 is slidingly provided with a straight slide block 4 that acts as a guide. The left side of the straight slide block 4 is equipped with a mounting block 5, and the straight slide block 4 is connected by welding. The installation block 5 is connected with the installation block 5 in the same way, the left side of the installation block 5 is fixedly connec...

Embodiment 2

[0018] A kind of aquaculture inlet pipe strainer cleaner, such as Figure 1-2 As shown, it includes a pole 1, a handle 2, a straight slide rail 3, a straight slide block 4, a mounting block 5, a mounting plate 6, a deep groove ball bearing 8, a rotating shaft 9, a wiping device 10, a mounting rod 11, and a rotating motor 12 , power supply 121, pulley 13, flat belt 14, swing bar 15, handle 151 and stay cord 16, the top of pole 1 is equipped with handle 2, and the bottom of pole 1 left side is embedded with straight slide rail 3, straight slide The sliding type on the rail 3 is provided with a straight-running slider 4 that acts as a guide, and the left side of the straight-running slider 4 is equipped with a mounting block 5, and the left side of the mounting block 5 is fixedly connected with a mounting plate 6, and the upper part of the mounting plate 6 is opened. There is a through hole 7, and two deep groove ball bearings 8 are installed in the through hole 7, and a rotating...

Embodiment 3

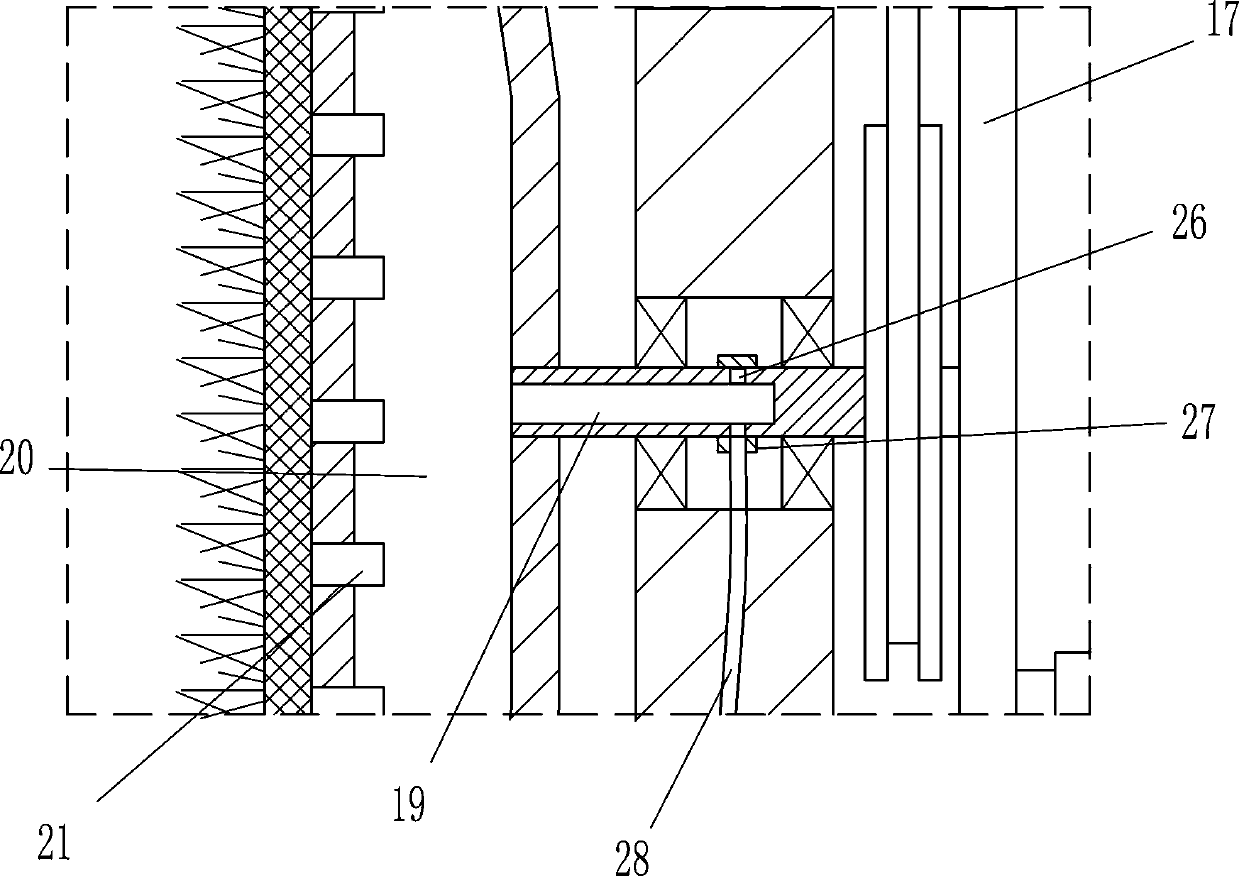

[0021] A kind of aquaculture inlet pipe strainer cleaner, such as Figure 1-3As shown, it includes a pole 1, a handle 2, a straight slide rail 3, a straight slide block 4, a mounting block 5, a mounting plate 6, a deep groove ball bearing 8, a rotating shaft 9, a wiping device 10, a mounting rod 11, and a rotating motor 12 , power supply 121, pulley 13, flat belt 14, swing bar 15, handle 151 and stay cord 16, the top of pole 1 is equipped with handle 2, and the bottom of pole 1 left side is embedded with straight slide rail 3, straight slide The sliding type on the rail 3 is provided with a straight-running slider 4 that acts as a guide, and the left side of the straight-running slider 4 is equipped with a mounting block 5, and the left side of the mounting block 5 is fixedly connected with a mounting plate 6, and the upper part of the mounting plate 6 is opened. There is a through hole 7, and two deep groove ball bearings 8 are installed in the through hole 7, and a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com