Heavy-industry machine platform

A heavy industry and guide rail technology, applied in metal processing and other directions, can solve problems such as time-consuming, unfavorable workpiece positioning, and potential safety hazards, and achieve the effect of short use time and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

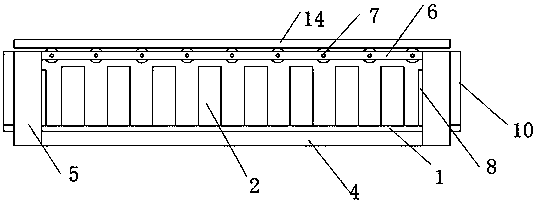

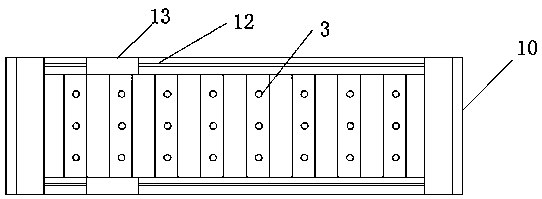

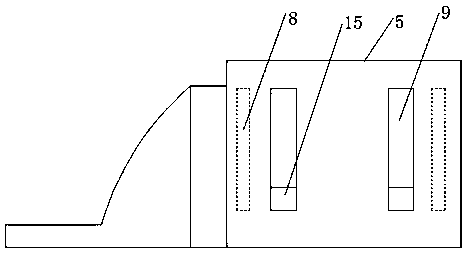

[0025] A heavy industry machine table, including a base, on which there are evenly distributed a plurality of parallel horizontal shelf plates, and a plurality of mounting holes for fixing workpieces are arranged on the horizontal shelf plates, and a lifting cylinder is arranged under the base, which is located on the base One side of the base is provided with a vacuum cleaner, two ends of the base are respectively provided with side plates, and the top of the two side plates is provided with a conveyor belt, and the two sides of the conveyor belt in the feeding direction are respectively provided with second guide rails, and the two second guide rails are respectively installed There are side rulers. A plurality of feed rollers in the conveyor belt are arranged at intervals with a plurality of horizontal frame plates, guide rails are provided on the inside of the side plates, track grooves corresponding to the guide rails are respectively provided at both ends of the base, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com