Voice Coil Actuator with Integrated LVDT

a voice coil actuator and voice coil technology, applied in the direction of dynamo-electric components, dynamo-electric machines, instruments, etc., can solve the problems of not having position feedback sensing capabilities and operating too slowly for most applications, and achieve accurate armature position sensing and rapid and accurate focus through the lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

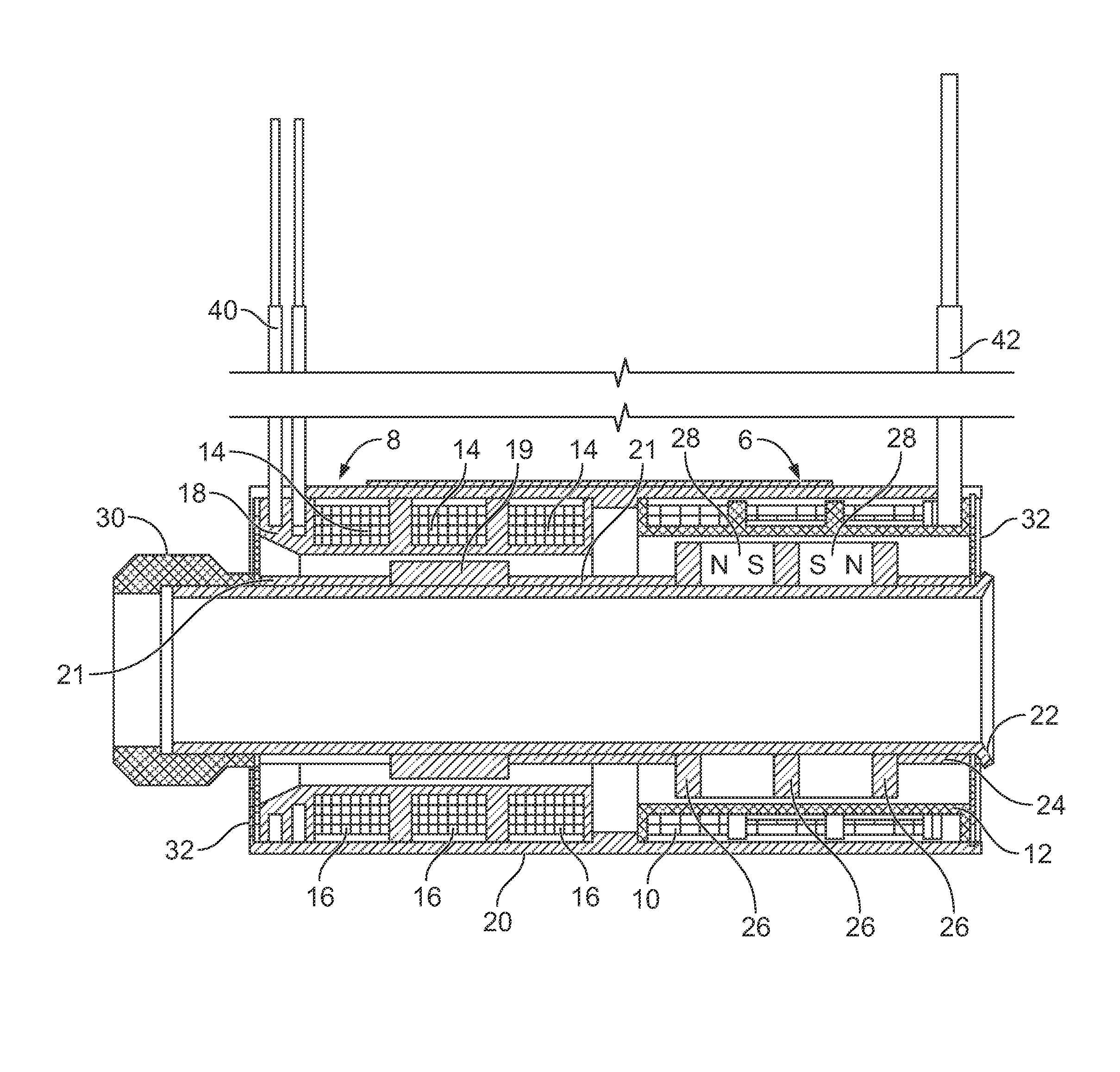

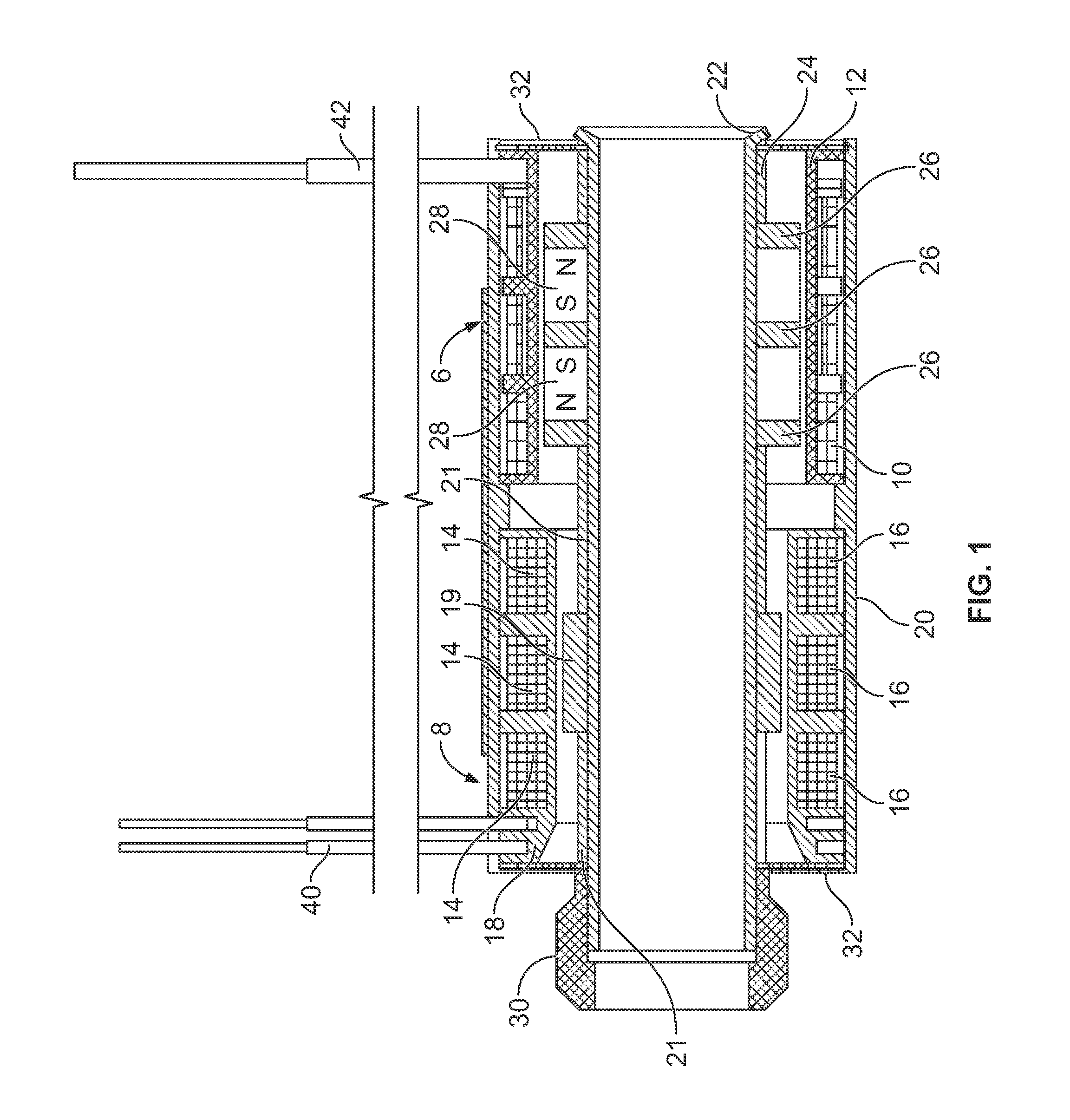

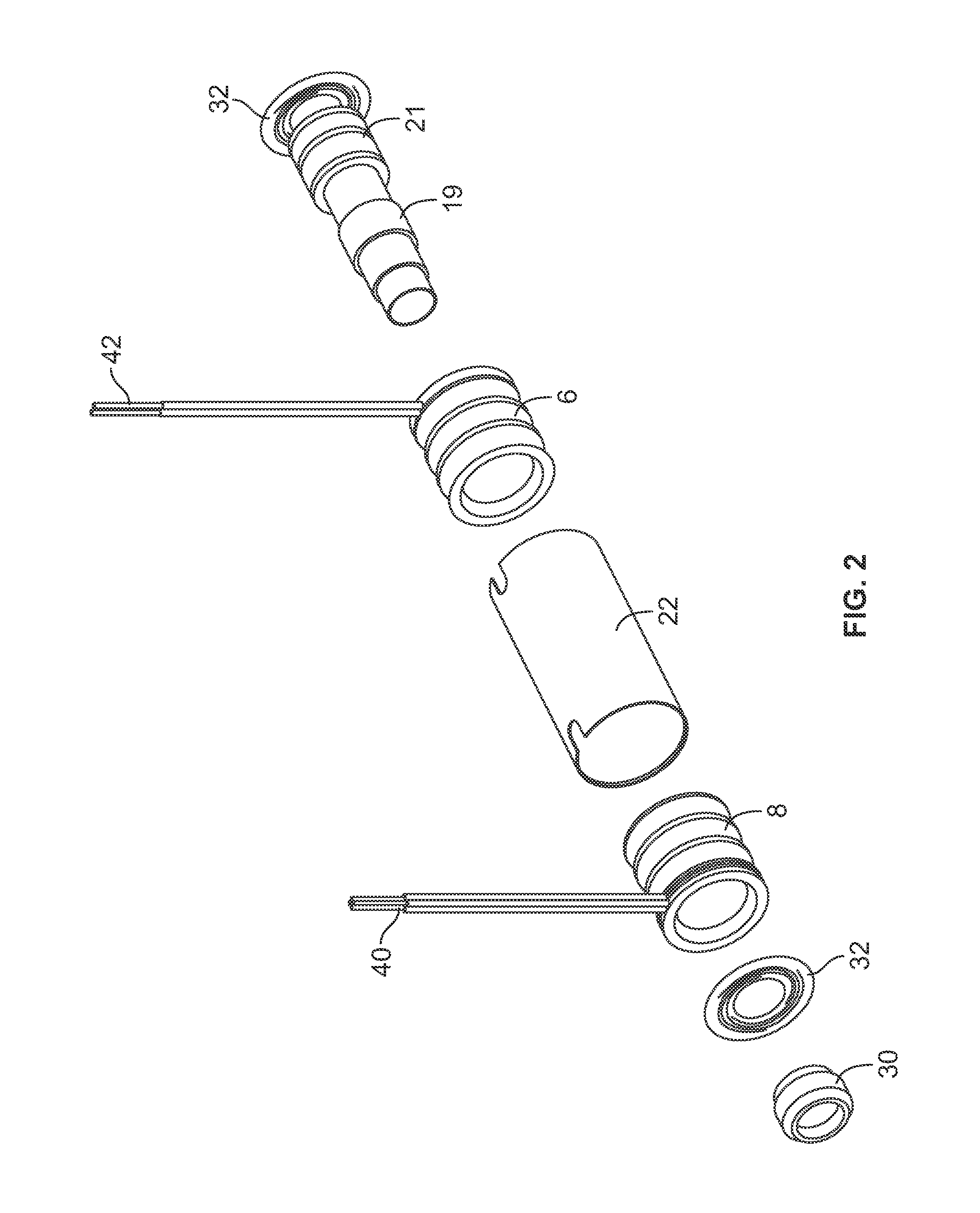

[0010]Turning first to FIG. 1 there are a voice coil 6 and a linear voltage displacement transducer (referred to herein as “LVDT”) sensor 8. As seen, these two devices are mounted together as a singular device. There are voice coil windings 10 with multiple coils windings in opposite winding directions for the voice coil 6 which are wound over a voice coil bobbin 12. There are LVDT primary windings 14 wound in the center of the LVDT bobbin 18 and the LVDT secondary windings 16 wound on the outside ends of the LVDT bobbin 18. There is a LVDT core 19 and non magnetic spacers 21 around the LVDT bobbin 18. The LVDT primary windings 14 and secondary windings 16 are housed in a ferromagnetic housing 20.

[0011]The voice coil 6 is comprised of a moving armature assembly 21 which consists of a unitary piece non-magnetic core tube 22, which may be made of brass, non-magnetic spacers 24, which also may be made of brass, multiple ferromagnetic armatures 26, and multiple permanent magnets 28 in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com