Straight tube pin hook type spherical omnidirectional wheel

A universal wheel and pin-hook type technology, applied in the field of universal wheels, can solve the problems of damage to the locking mechanism, failure to achieve the effect, too flexible movement, etc., and achieve the effect of simple production, easy realization, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

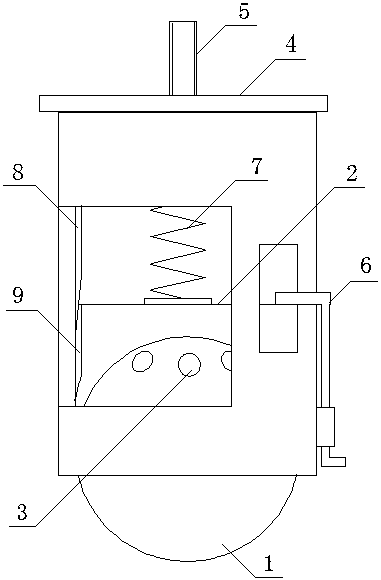

[0015] Such as figure 1 As shown, a straight pin-hook type spherical universal wheel includes a rolling ball 1, an inner cylinder 2 covering the rolling ball 1, and several guide guides in contact with the surface of the rolling ball are arranged above the inside of the inner cylinder 2. Ball 3, an outer cylinder 4, the top of the outer cylinder 4 is equipped with fixing bolts 5 for connecting with other devices, a pin hook assembly 6 is arranged on the outer circumference of the outer cylinder 4, the pin hook assembly 6 includes a fixed frame, and is installed on a fixed On the frame, the pin hook pivoted by the fixed frame is provided with a pin hook groove on the outer cylinder body, and the hook of the pin hook penetrates into the pin hook groove to press on the top surface of the inner cylinder body, and the inner height of the outer cylinder body is greater than that of the inner cylinder body. The combined height of cylinder and rolling ball.

[0016] The pin hook asse...

Embodiment 2

[0018] As a structural design of Example 1, a compression spring 7 is arranged inside the outer cylinder 4 , one end of the compression spring 7 bears against the top surface of the inner cylinder 2 , and the other end bears against the inner surface of the top of the outer cylinder 4 .

[0019] The inner cylinder 2 and the outer cylinder 4 are cylinders, a spring sleeve is arranged at the center of the top surface of the inner cylinder 2, a spring sleeve is arranged at the center of the inner top surface of the outer cylinder 4, and the two ends of the compression spring 7 are respectively located Inside the two spring sleeves.

[0020] This embodiment is an optimized design of Example 1. A compression spring 7 is arranged between the inner cylinder body 2 and the inner cavity of the outer cylinder body 4, and the shock absorption is realized through the compression spring 7, so as to protect the structure of the present invention and enable the The rolling ball is firmly in ...

Embodiment 3

[0022] As a further structural design of Example 2, two pin hook assemblies 6 are provided, and the outer cylinder 4 is arranged symmetrically.

[0023] A guide protrusion 8 is arranged inside the outer cylinder 4 , and a guide groove 9 is arranged on the upper outer surface of the inner cylinder, and the guide protrusion 8 is located in the guide groove 9 .

[0024] The design of this implementation example takes into account the ease of use of the pin hook assembly and the cooperation between the outer cylinder and the inner cylinder. During operation, the mutual rotation between the outer surface of the inner cylinder and the inner surface of the outer cylinder is reduced. friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com