Bottle arranging and separating device and method

A sorting device and bottle unscrambling technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low efficiency of sorting, sorting, and conveying, so as to improve the overall speed of splitting and conveying, avoid mutual crowding, and increase guidance The effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

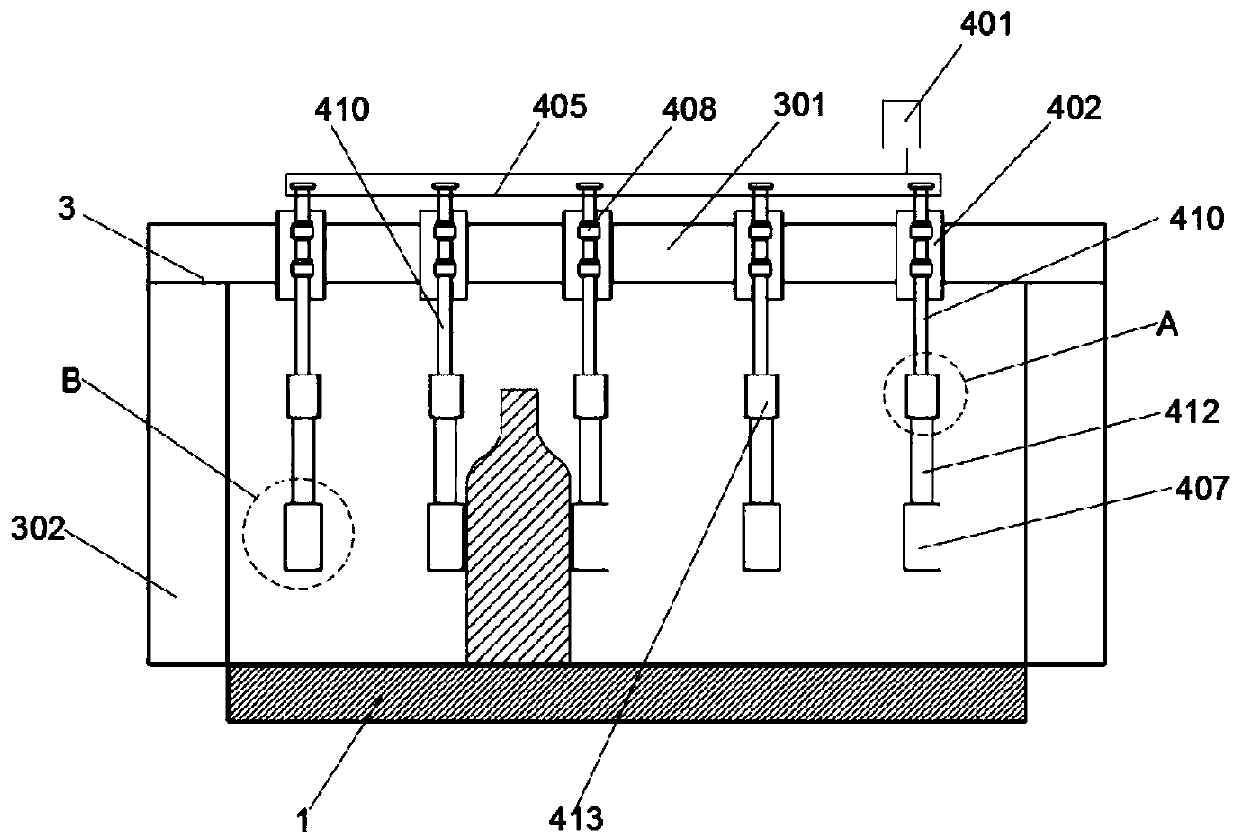

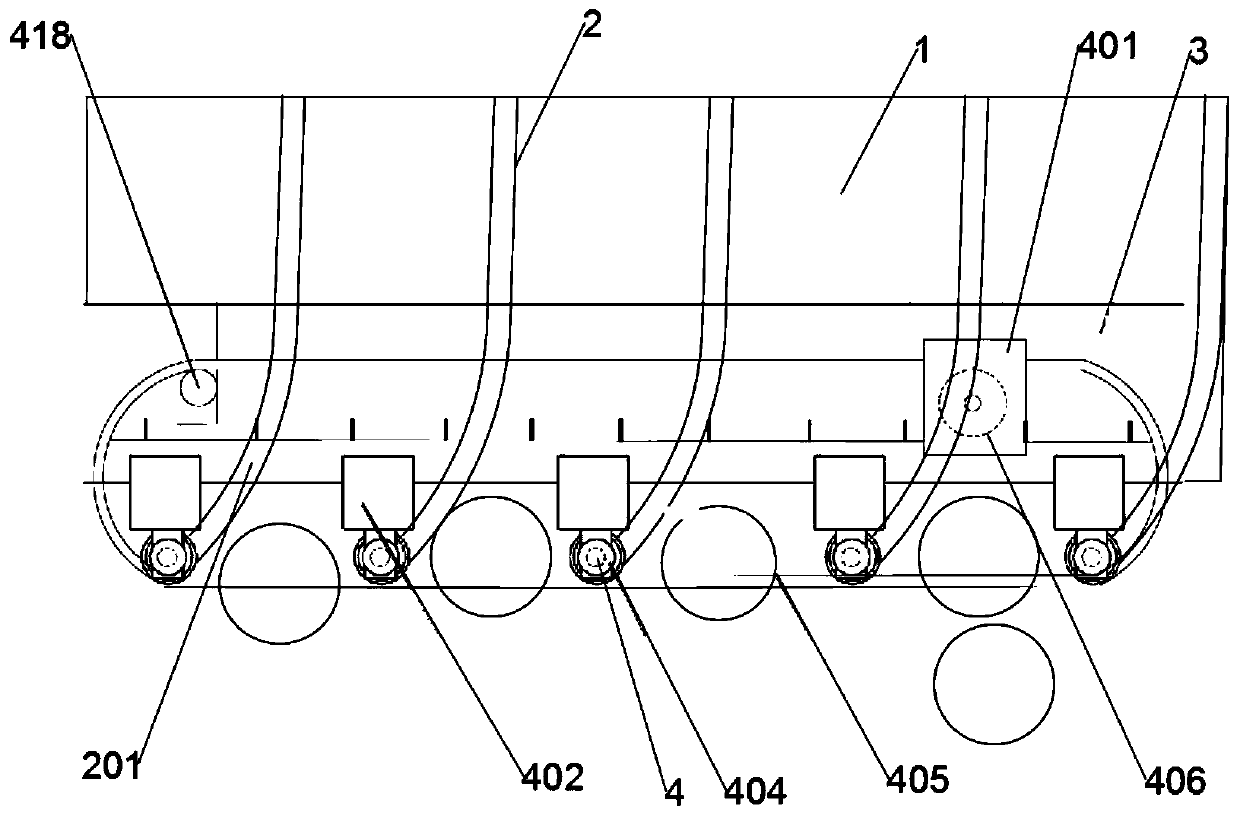

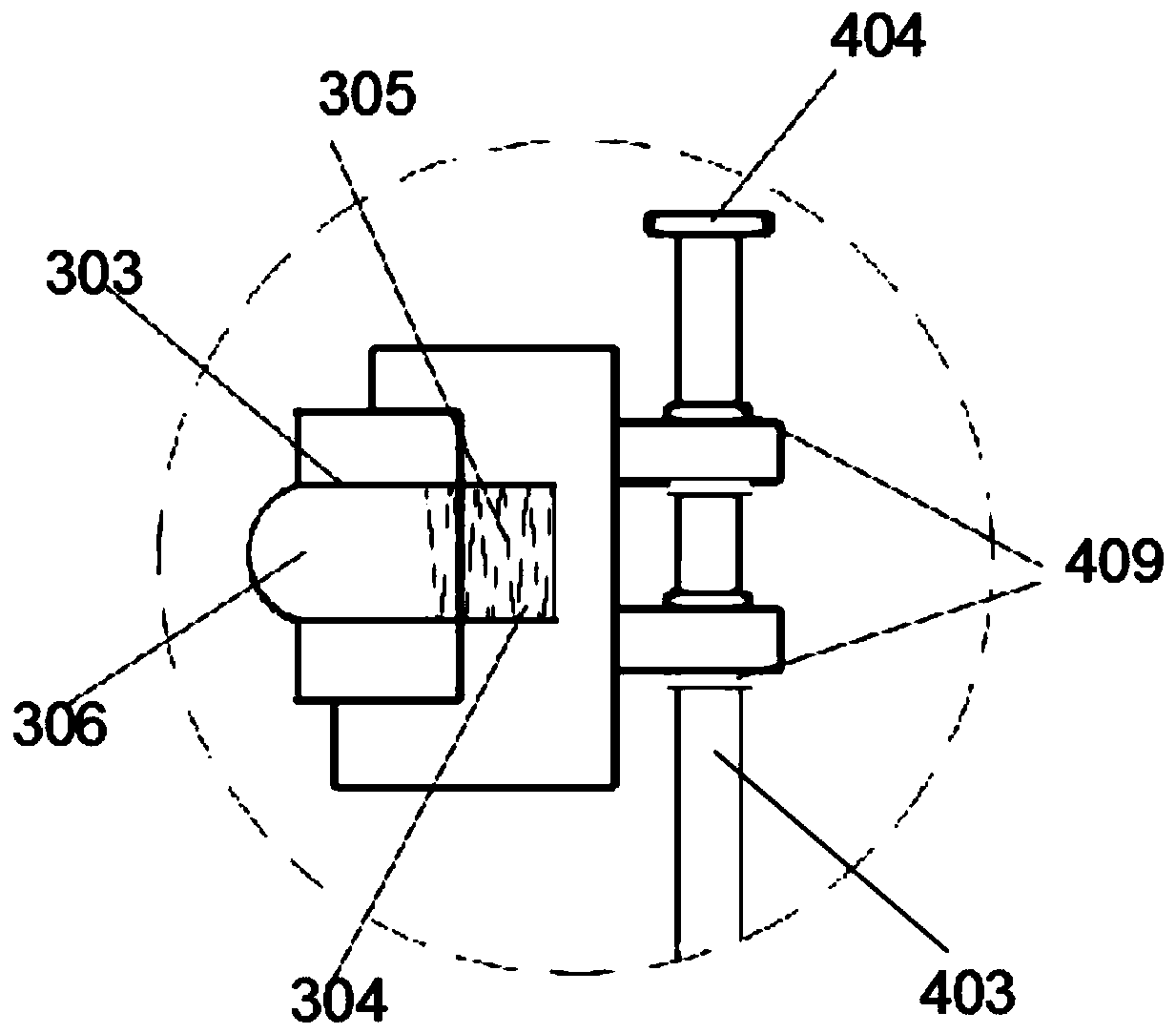

[0037] Such as Figure 1 to Figure 6 As shown, the present invention provides a kind of bottle unscrambling and distributing device, comprises the bottle unscrambling conveyer belt 1 that is used for conveying bottle material in batches, is provided with on the bottle unscrambling conveyer belt 1 and is used for carrying out the several distributing barriers 2 that bottle material is carried out individual separation transmission, A track for a bottle material to pass is formed between two adjacent material distribution fences 2 . Preferably, the feeding end of the material distribution fence 2 is provided with an arc-shaped partition baffle 201, and the inner side wall of the arc-surface partition baffle 201 is tangent to the side wall of the bottle material. Across the bottle unscrambling conveyor belt 1 and at the feeding end of the material distribution fence 2, a gantry support 3 as a bearing mechanism for various parts is provided. The distribution device 4 for accelera...

Embodiment 2

[0046] Such as Figure 7 Shown, a kind of bottle unscrambling method of bottle unscrambling distribution device comprises steps:

[0047] Step 100, setting a number of side-by-side distribution fences that can only accommodate one bottle material on the bottle unscrambling conveyor belt for conveying the bottle material;

[0048] Step 200, setting rod-shaped parts that can rotate synchronously between the front ends of adjacent material distribution fences;

[0049] Step 300, when the bottle material is in contact with the rod-shaped part, the bottle material is driven to rotate by means of the friction between the rod-shaped part and the bottle material;

[0050] Step 400, the bottle material gradually enters the corresponding material distribution fence under the rotating force of the corresponding rod-shaped component.

[0051] Preferably, the inlets of the several material distribution fences all face the arc-shaped structure on the same side, and there is a rod-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com