A kind of molybdenum removal method of ammonium tungstate liquid

A technology of ammonium tungstate and feed liquid, applied in chemical instruments and methods, preparation of tungsten compounds, tungsten compounds, etc., can solve the problems of low molybdenum saturated adsorption capacity, poor adsorption effect, and inability to make full use of resin adsorption capacity, etc. To achieve the effect of ensuring the desorption effect and good desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

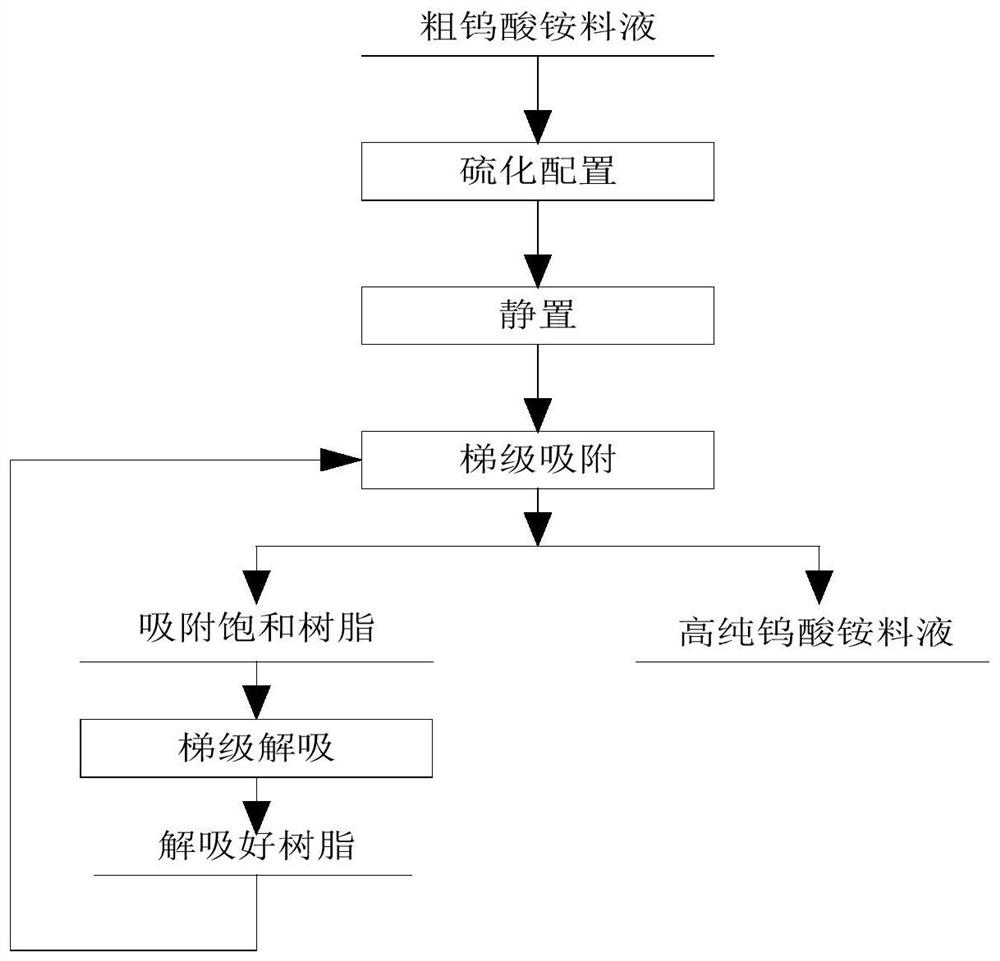

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for removing molybdenum from ammonium tungstate feed liquid, comprising:

[0030] In the vulcanization step, ammonium sulfide is added to the ammonium tungstate feed liquid as a vulcanizing agent, and stirred for 4 hours. After the stirring is completed, the concentration of molybdenum is 1.15g / L, S 2- The ion concentration is 3.06g / L, let it stand for 72 hours, and use a precision filter to remove particles and suspended solids in the feed liquid to make a vulcanized feed liquid.

[0031] In the cascade adsorption step, the vulcanization material liquid is adsorbed once through WDA918 resin. The mass of WDA918 resin is 467g, and the flow rate of the vulcanization material liquid is controlled at 15ml / min to obtain the liquid after the first adsorption. The concentration of molybdenum in the liquid after the first adsorption is controlled to be ≤0.1g / L, when it reaches 0.1g / L, it is the primary adsorption saturation, and the adsorption...

Embodiment 2

[0034] This embodiment provides a method for removing molybdenum from ammonium tungstate feed liquid, comprising:

[0035] In the vulcanization step, add ammonium sulfide as a vulcanizing agent to the ammonium tungstate feed liquid, stir for 8 hours, and after the stirring is completed, the molybdenum concentration is 1.15g / L, S 2- The ion concentration is 3.06g / L, stand still for 36 hours, and use a precision filter to remove particles and suspended solids in the feed liquid to make a vulcanized feed liquid;

[0036] In the cascade adsorption step, the simulated exchange column I (model φ5cm×70cm) was loaded with 467g of WDA918 resin, and the simulated exchange column II (model φ5cm×70cm) was loaded with 467g of 201×7 resin. Put the vulcanized feed liquid into the simulated exchange column I, and carry out primary adsorption by WDA918 resin. The flow rate of the vulcanized feed liquid is controlled at 20ml / min to obtain the liquid after the primary adsorption. When it reache...

Embodiment 3

[0041] This embodiment provides a method for removing molybdenum from ammonium tungstate feed liquid, comprising:

[0042] In the vulcanization step, ammonium sulfide is added to the ammonium tungstate feed solution as a vulcanizing agent, and stirred for 6 hours. After the stirring is completed, the molybdenum concentration is 2.5g / L, S 2- The ion concentration is 4.56g / L, let it stand for 54 hours, and use a precision filter to remove particles and suspended solids in the feed liquid to make a vulcanized feed liquid;

[0043] In the cascade adsorption step, the simulated exchange column I (model φ5cm×70cm) was loaded with 467g of WDA918 resin, and the simulated exchange column II (model φ5cm×70cm) was loaded with 467g of 201×7 resin. Put the vulcanized feed liquid into the simulated exchange column I, and carry out primary adsorption by WDA918 resin. The flow rate of the vulcanized feed liquid is controlled to be 25ml / min to obtain the liquid after the primary adsorption. W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com