Surface cleaning device of drying roller after acid tank

A surface cleaning and squeezing roller technology, which is applied in the field of surface cleaning devices for squeezing rollers after acid tanks, can solve the problems of manufacturers such as economic pressure, corrosion, oxidation, and damage, and achieve the effect of reducing customer complaints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

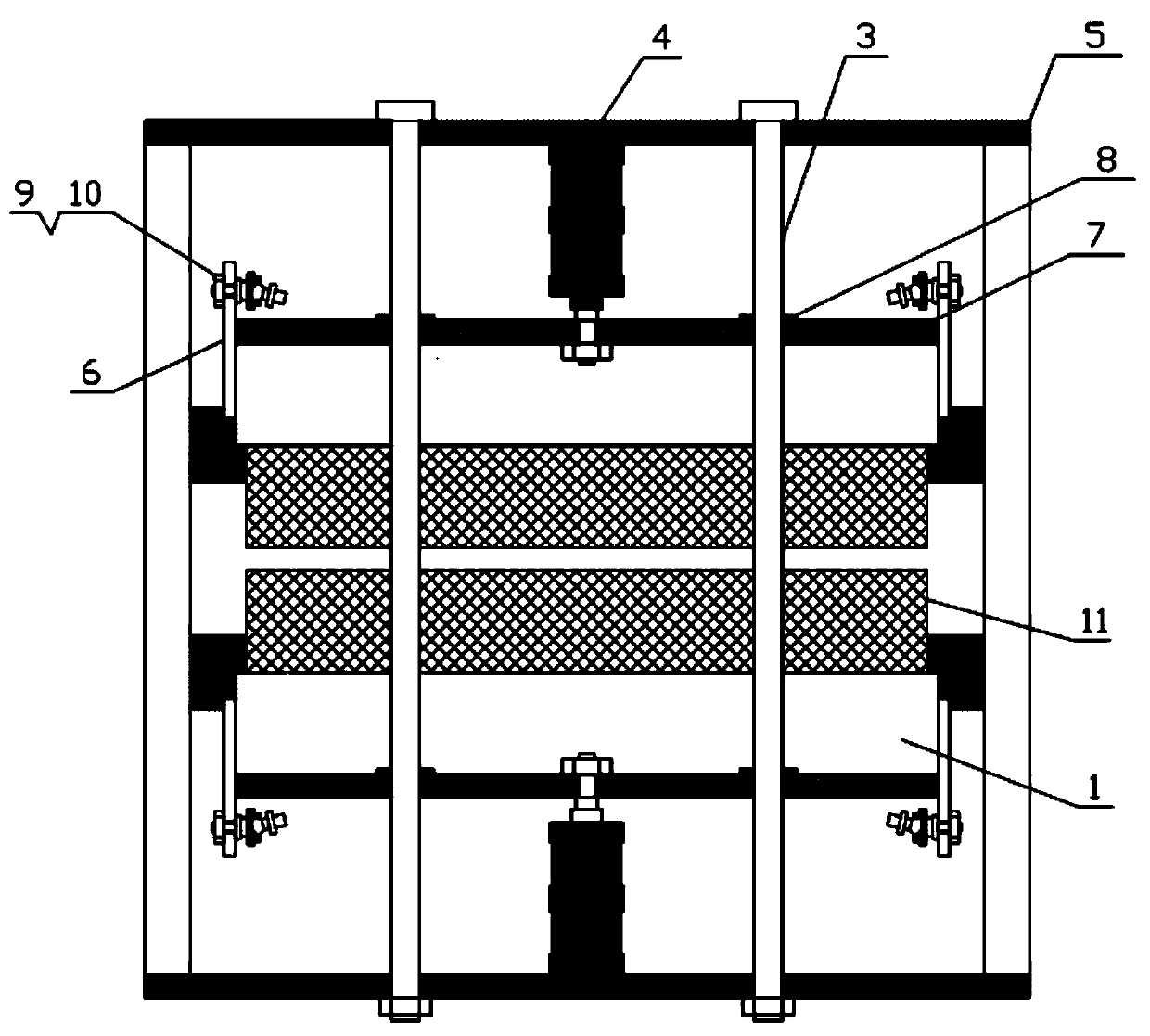

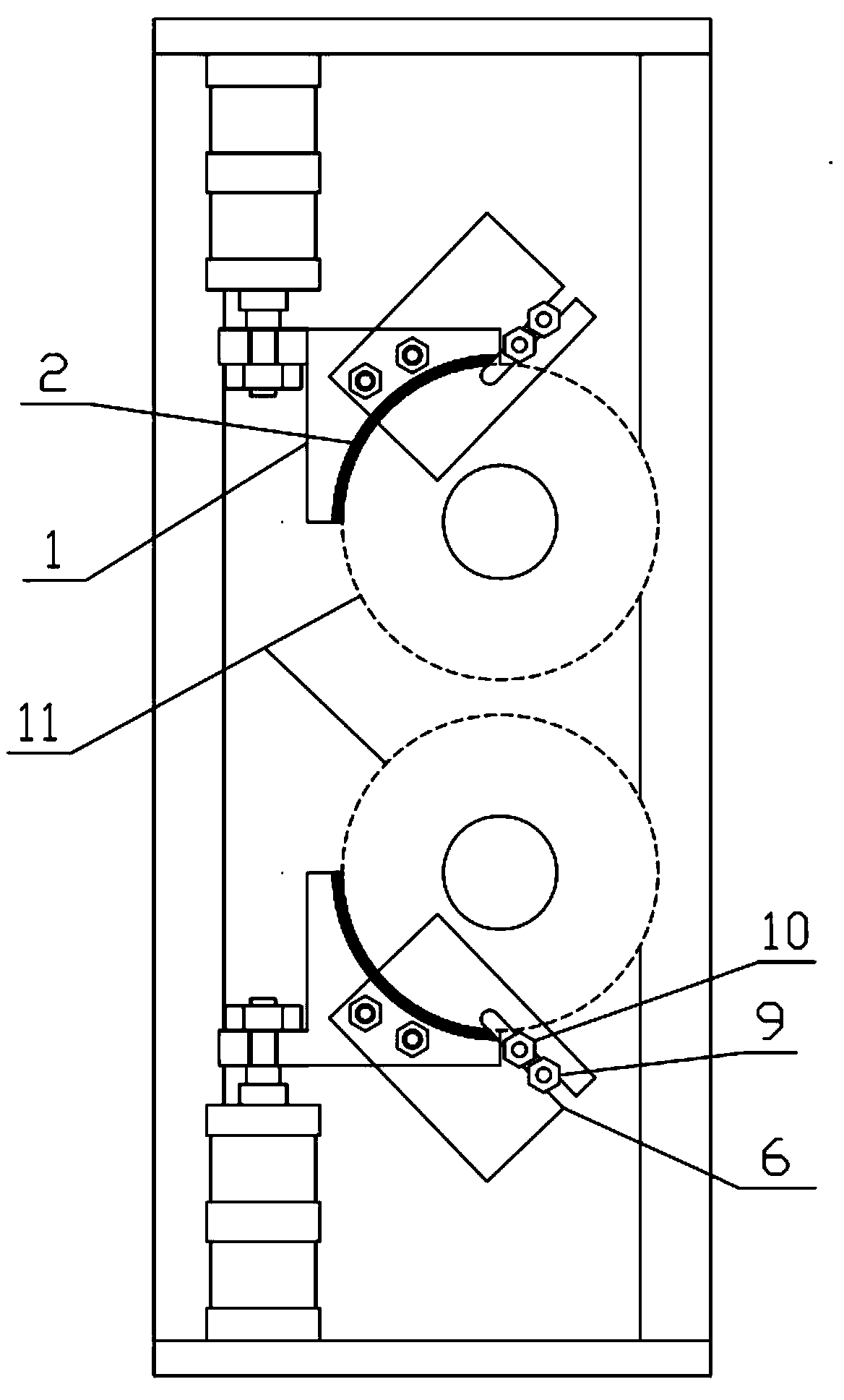

[0019] Such as figure 1 and figure 2 As shown, this kind of cleaning device for the surface of the squeeze roller after the acid tank is added to the surface of the upper and lower two squeeze rollers 11 behind the acid tank, because the squeeze roller 11 is a passive roller, and the installation position of the cleaning device is on the surface of the squeeze roller. 11 near one end of the acid tank.

[0020] Including a mounting base 1, an arc-shaped cleaning scraper 2 close to the drying roller 11 is installed on the mounting base 1, and a universal water nozzle 9 that sprays water and air toward the cleaning scraper 2 is also installed on the mounting base 1 And universal air nozzle 10. The universal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com