Vertical force measuring type bridge support and force measuring method

A bridge support and force measurement technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of limited service life of the force measurement function of the support, affect the service life, and difficulty in replacement, and achieve easy replacement, easy disassembly, and reduction Effect of small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

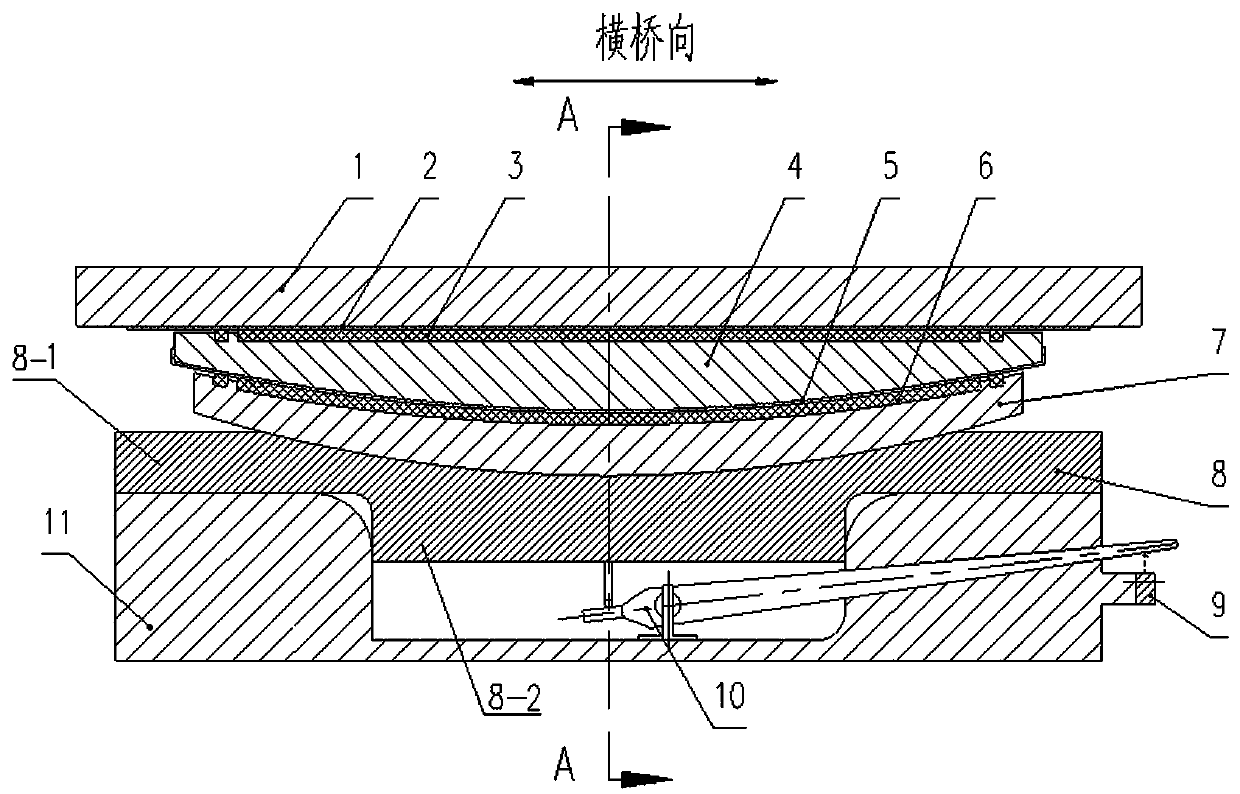

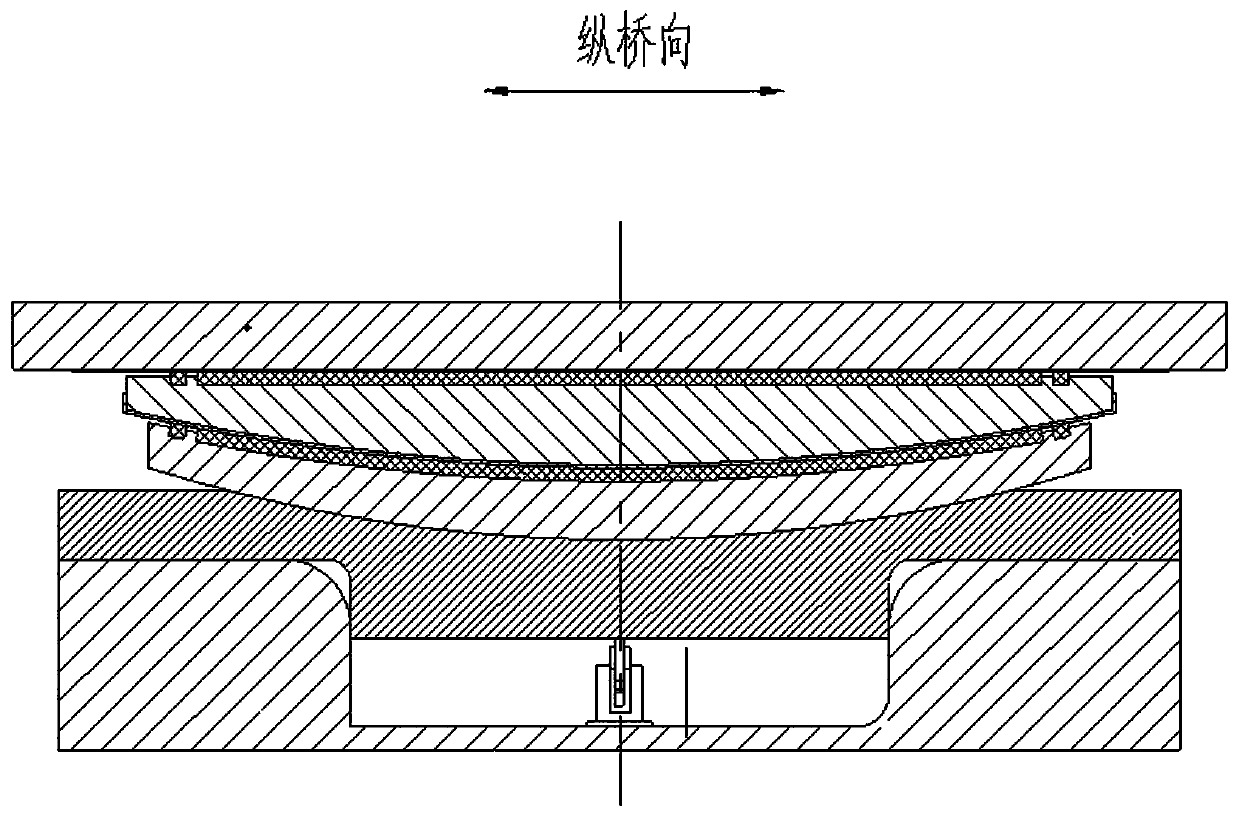

[0051] Given the multi-directional movable vertical force-measuring spherical steel bearing, such as figure 1 , 2 shown. It mainly consists of upper seat plate 1, upper stainless steel slide plate 2, upper non-metallic slide plate 3, middle seat plate 4, lower spherical stainless steel slide plate 5, lower spherical non-metallic slide plate 6, lower seat plate 7, seat plate 8, displacement sensor 9, displacement Amplifying device 10, bottom basin 11 etc. parts are formed. There is a plane friction pair between the upper seat plate 1 and the middle seat plate 4 (the upper stainless steel slide plate 2 and the upper non-metallic slide plate 3); there is a spherical friction pair between the middle seat plate 4 and the lower seat plate 7 (the lower spherical stainless steel slide plate 5 and The lower spherical non-metallic slide plate 6), the plane friction pair and the spherical friction pair together form the vertical pressure-bearing friction pair of the support, which has ...

Embodiment 2

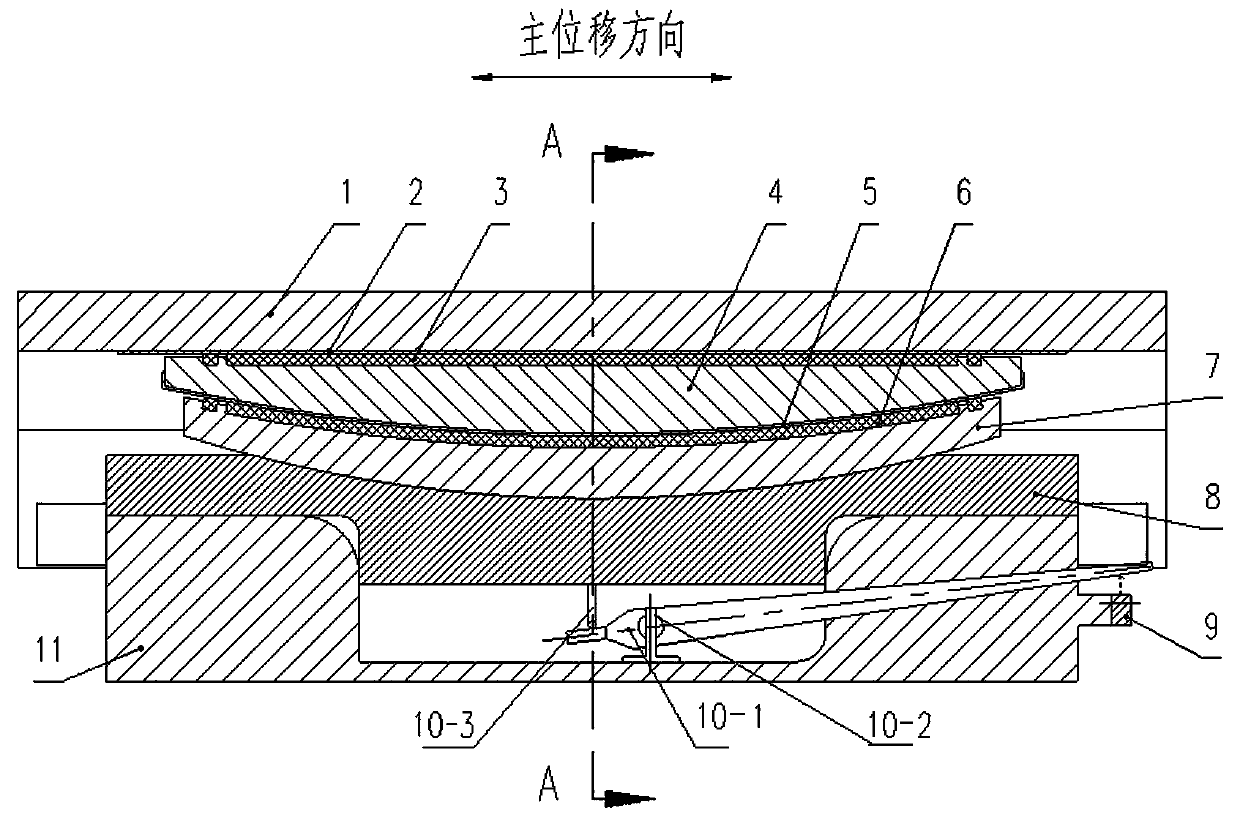

[0055] Given a one-way movable vertical force-measuring spherical steel bearing, such as image 3 , 4 shown. It mainly consists of upper seat plate 1, upper stainless steel slide plate 2, upper non-metallic slide plate 3, middle seat plate 4, lower spherical stainless steel slide plate 5, lower spherical non-metallic slide plate 6, lower seat plate 7, seat plate 8, displacement sensor 9, displacement Amplifying device 10, bottom basin 11 etc. parts are formed. There is a plane friction pair between the upper seat plate 1 and the middle seat plate 4 (the upper stainless steel slide plate 2 and the upper non-metallic slide plate 3); there is a spherical friction pair between the middle seat plate 4 and the lower seat plate 7 (the lower spherical stainless steel slide plate 5 and The lower spherical non-metallic slide plate 6 is formed), the two horizontal limit directions of the bottom basin 11 and the upper seat plate 1 have guiding friction pairs (made up of a guiding stainl...

Embodiment 3

[0059] Given a fixed vertical force-measuring spherical steel support, such as Figure 5 , 6 shown. It mainly consists of upper seat plate 1, upper stainless steel slide plate 2, upper non-metallic slide plate 3, middle seat plate 4, lower spherical stainless steel slide plate 5, lower spherical non-metallic slide plate 6, lower seat plate 7, seat plate 8, displacement sensor 9, displacement Amplifying device 10, bottom basin 11 etc. parts are formed. There is a plane friction pair between the upper seat plate 1 and the middle seat plate 4 (the upper stainless steel slide plate 2 and the upper non-metallic slide plate 3); there is a spherical friction pair between the middle seat plate 4 and the lower seat plate 7 (the lower spherical stainless steel slide plate 5 and The lower spherical non-metallic slide plate 6); the plane friction pair and the spherical friction pair together form the vertical pressure-bearing friction pair of the support, which has the functions of vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com