Elastic sealing flooding plug structure

An elastic sealing, spring energy storage technology, applied in the direction of cocks, engine components, mechanical equipment, etc. including cut-off devices, can solve problems such as internal leakage of valves, and achieve the effect of ensuring tightness and eliminating leakage risks.

Pending Publication Date: 2019-08-09

JIANGSU SHENTONG VALVE

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the valve is opened or closed, the force generated by the rotation of the ball will drive the polymer such as PCTFE to move in the holder, thereby forming a leakage channel, which will cause internal leakage of the valve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

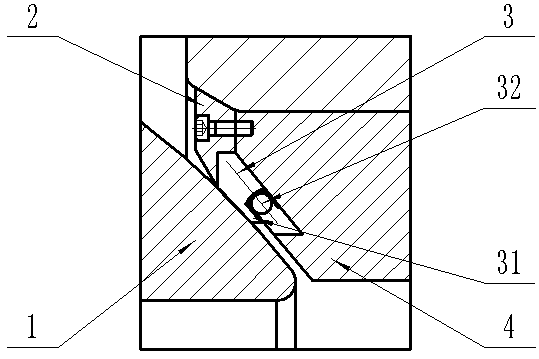

[0009] Such as figure 1 As shown in the figure, an elastic sealing pan-seal structure includes a sphere, a limit block, a pan-seal, and a retainer. The pan-seal is composed of an outer lip and an inner spring energy storage ring. In the groove, the limit block is fixedly connected with the fixer, the limit block abuts against the Variseal, and the outer lip of the Variseal abuts against the surface of the sphere.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

An elastic sealing flooding plug structure comprises a sphere, a limiting block, a flooding plug and a fixer, wherein the flooding plug consists of an outer lip and an inner spring energy storage ring, the flooding plug is embedded in a mounting groove of the fixer, the limiting block is fixedly connected with the fixer, the limiting block abuts against the flooding plug, and the outer lip of theflooding plug abuts against the surface of the sphere. The elastic sealing flooding plug structure has the beneficial effects that under the ultra-low temperature working condition, although the shrinkage rates of the flooding plug and the fixer are not consistent, the gap between the flooding plug and the fixer can be made up through the spring energy storage ring inside the flooding plug, so that the leakage risk of the flooding plug and the fixer is eliminated, and the tightness of the valve is ensured.

Description

technical field [0001] The invention relates to an elastic sealing pan-seal structure. Background technique [0002] As a new energy source, LNG has broad development prospects. In recent years, with the involvement of energy companies such as PetroChina, Sinopec, and CNOOC in the LNG industry, more and more LNG receiving stations have been built in China, and a large number of cryogenic valves have been used in LNG receiving stations to realize LNG transportation. [0003] At present, ultra-low temperature ball valves account for more than 80% of the total cryogenic valves in LNG receiving stations, but the existing low temperature ball valves mostly use high molecular polymers such as PCTFE embedded in metal holders to achieve the seal between the ball and the valve seat. The structure specifically includes spheres, polymers such as PCTFE, springs, and fixers. When the valve works under low temperature conditions, because the linear expansion coefficient of high molecula...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): F16K5/20

CPCF16K5/201

Inventor 张清双吴春豪

Owner JIANGSU SHENTONG VALVE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap