Lifting facility

A technology of equipment and lifting devices, which is applied in the direction of conveyor objects, supporting frames, transportation and packaging, etc., can solve problems such as equipment collision damage, lifting asynchronous, lifting equipment can not meet the demand, etc., to improve the rotation accuracy , to eliminate the effect of butt joint gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] With reference to the drawings of the present invention, a technical solution of the embodiment of the invention will be further elaborated.

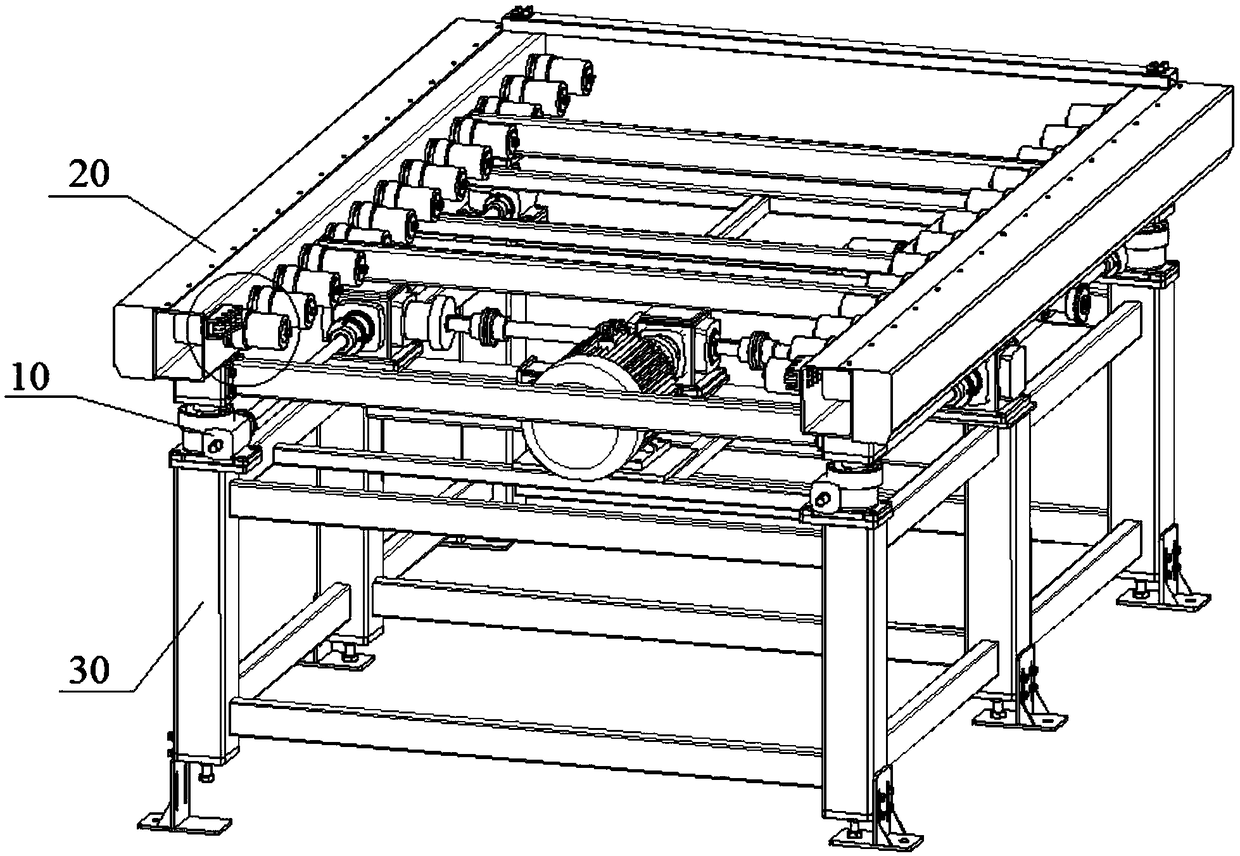

[0021] Reference attached figure 1 As shown, a lifting device includes a lifting device 10, a roller table device 20, and a fixing frame 30. The upper part of the lifting device 10 arranged on the fixing frame 30 is provided with a roller table device 20, and the lifting device 10 is used for lifting Lift roller device 20.

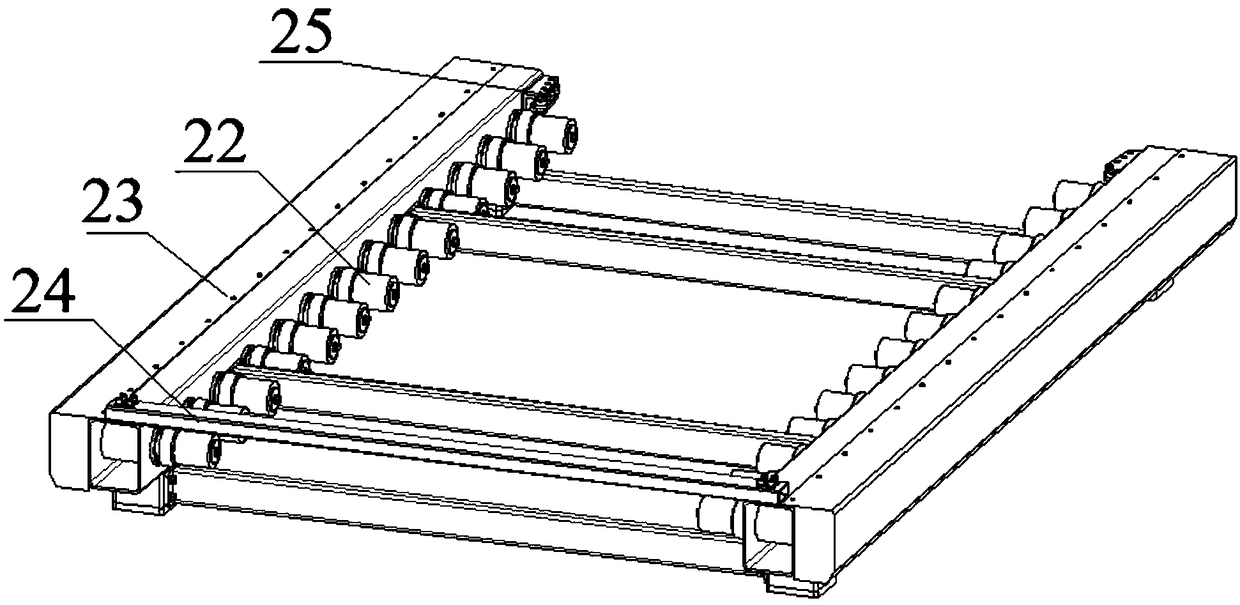

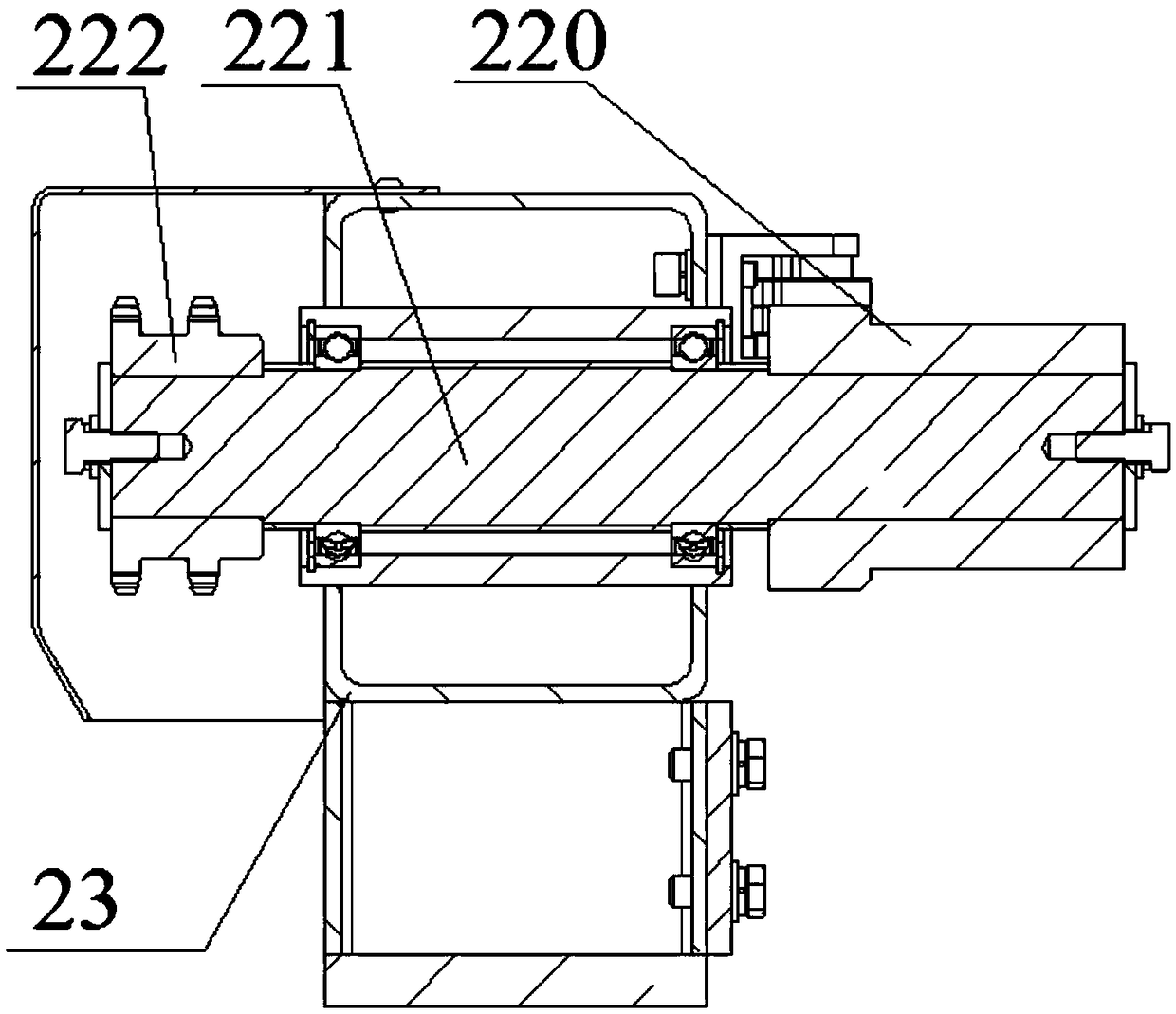

[0022] Reference attached figure 2 As shown, the roller table device 20 includes a roller table driving device 21, a roller table group 22, a roller table frame 23, a limiting device 24, and a guide device 25. The roller table group 22 includes a wheel body 220, a roller shaft 221, and a roller sprocket. 222. Chain, refer to attachment image 3 As shown, both sides of the upper part of the roller frame 23 are respectively mounted with a row of roller shafts 221, the roller shaft 221 on the opposite side of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com