Associated control device and method for screw hole detection and oiling of automobile door lock

A car door lock and related control technology, which is applied in the direction of measuring device, device for coating liquid on the surface, testing of mechanical parts, etc., can solve the problem of door lock assembly failure, waste of production cost, security inspection of door lock lock body assembly screw hole missing and other problems, to achieve the effect of convenient operation and avoid waste of materials and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

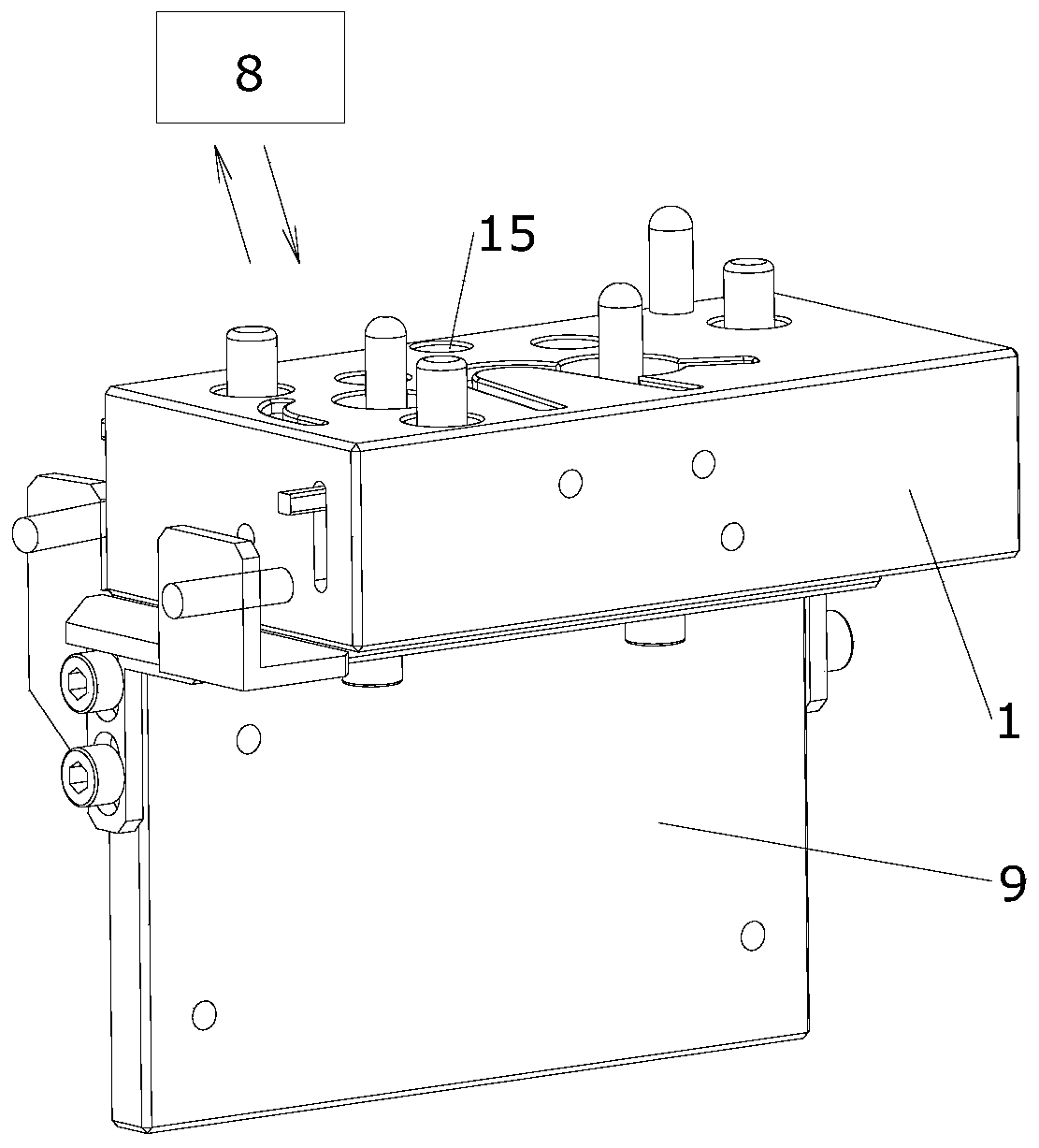

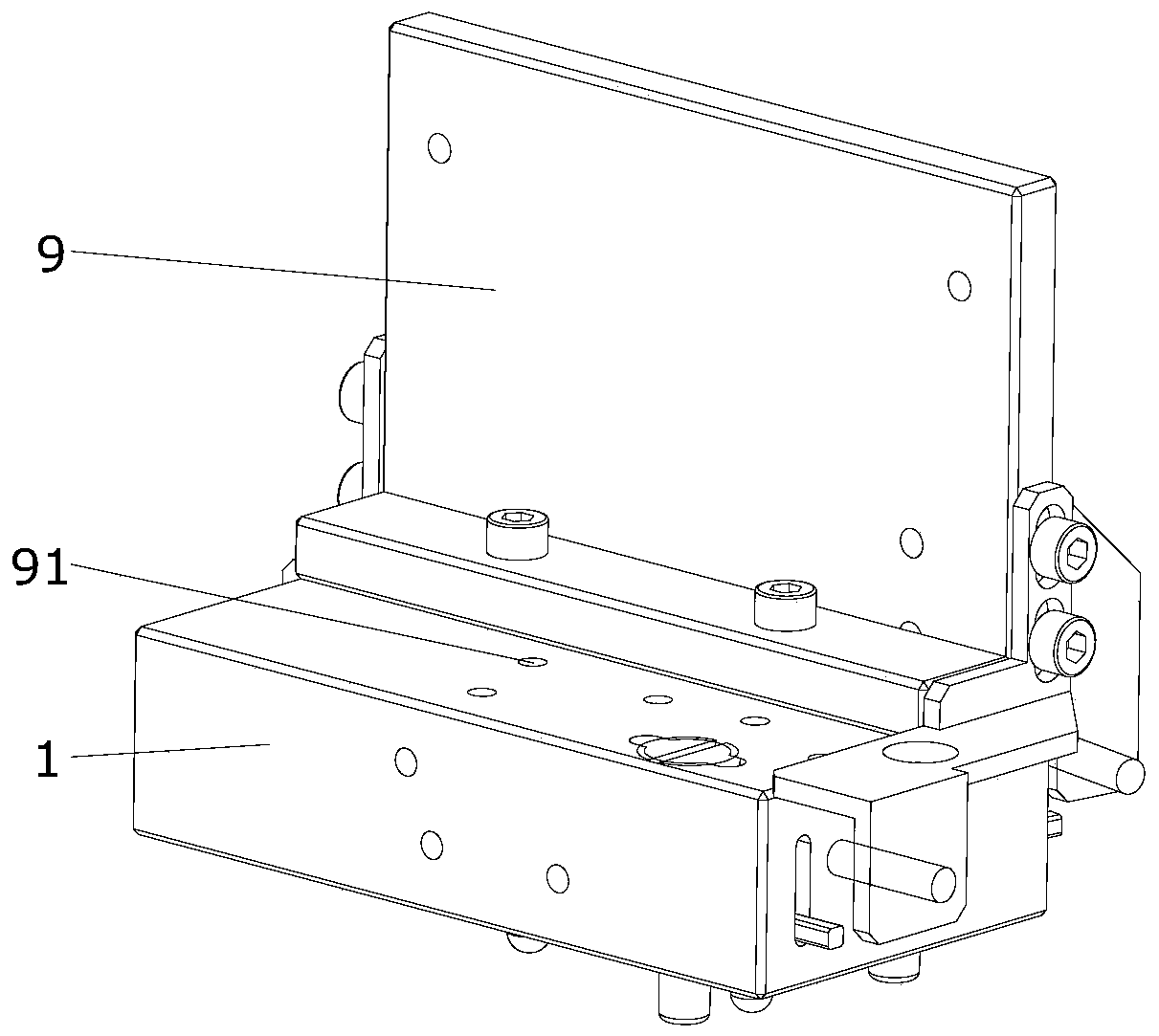

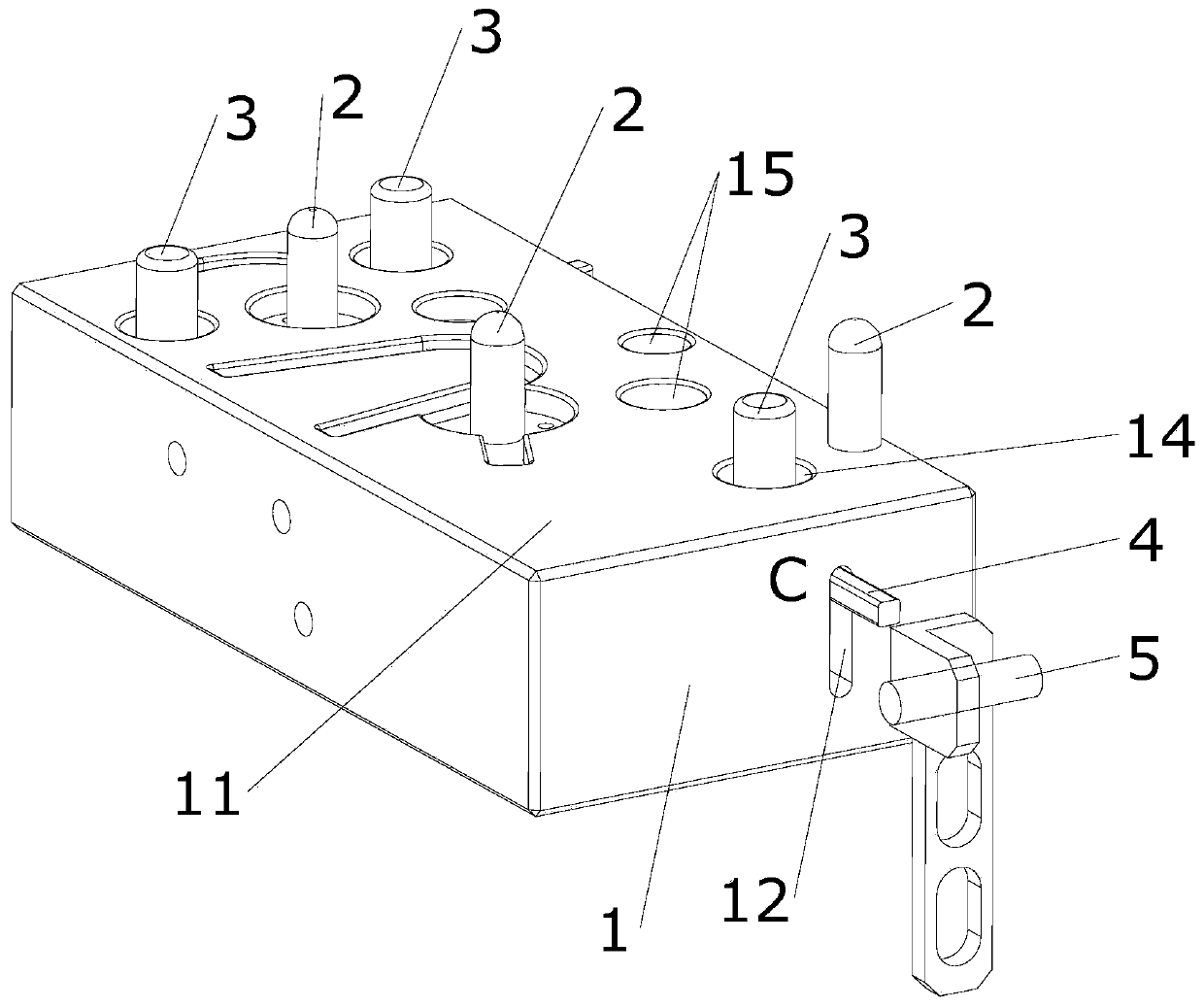

[0026] A correlative control device for threaded hole detection and oil filling of automobile door lock, as attached Figure 1~5 As shown, it includes a detection box 1, a positioning column 2, a control system 8, a base 9, a detection component, and an oil injection mechanism. The detection component includes a detection column 3, a probe 4, a sensor 5, an elastic member 6, and a locking base 7. The oil injection mechanism includes an oil injection pipeline.

[0027] Usually, the upper surface of the detection box 1 is used as the working surface 11, and there are at least three positioning columns 2. The positioning columns 2 are scattered and fixed on the working surface 11 and protrude from the working surface 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com