Method for measuring cigarette combustion rate

A measurement method and technology of burning rate, which is applied in the direction of chemical analysis by means of combustion, etc., can solve problems such as large errors in shredded tobacco, inability to accurately measure combustion performance, rough cigarette mass burning rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

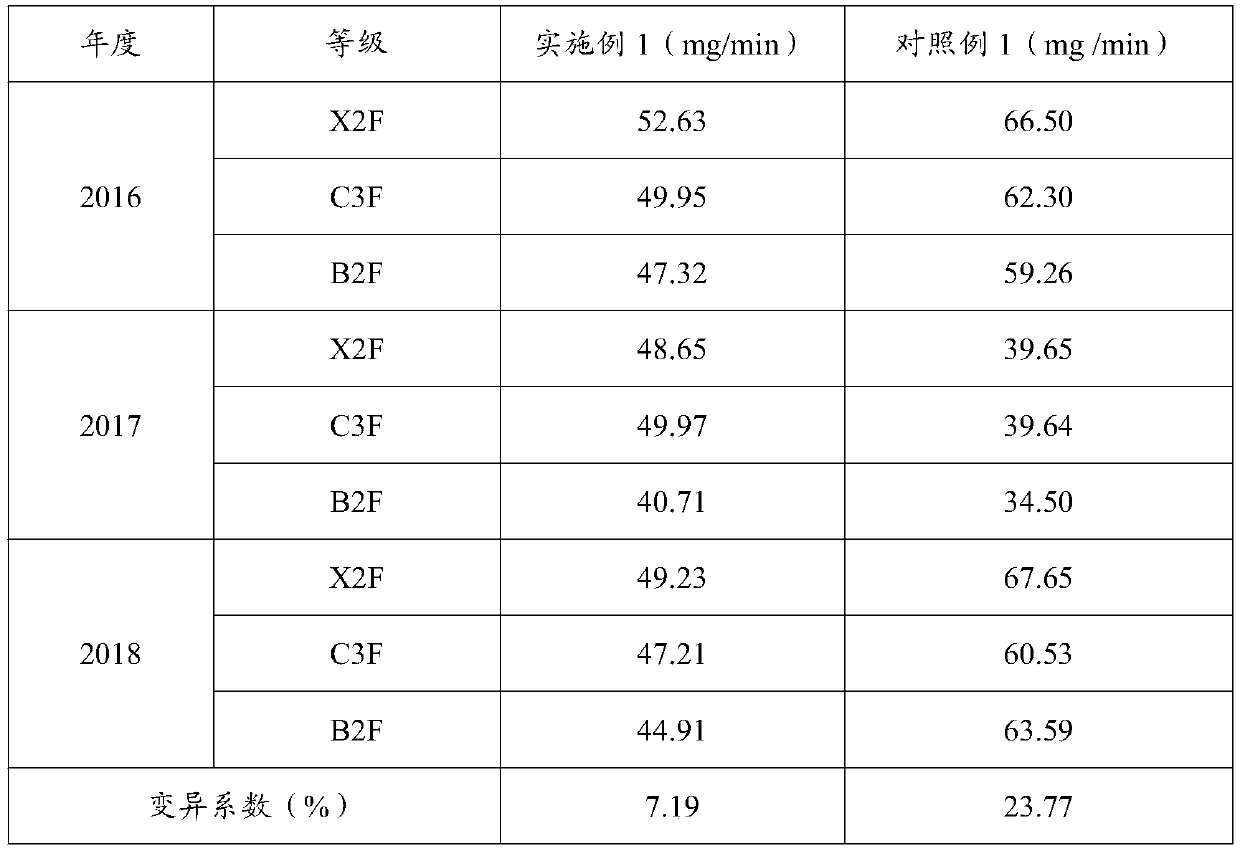

[0058] 1. Tobacco leaf sample selection: Select representative samples of different grades (X2F, C3F, B2F grades) in different years (2016, 2017, 2018) in the same production area, and take 500g of each as a tobacco leaf sample.

[0059] 2. Preparation of shredded tobacco samples: remove the stems of each tobacco leaf sample and cut into shredded tobacco with a width of 0.9±0.1 mm, mix well, and take 50 g of each portion as shredded tobacco samples.

[0060] 3. Preparation of balanced shredded tobacco sample: Take the cut shredded tobacco sample and put it in a constant temperature and humidity box, take it out after balancing for 72 hours under standard air conditions (temperature 22±1°C, relative humidity 60±3%), and stir it by hand every 4 hours during this period , to ensure that the moisture, temperature and humidity of the shredded tobacco sample are evenly balanced, and a balanced shredded tobacco sample is obtained.

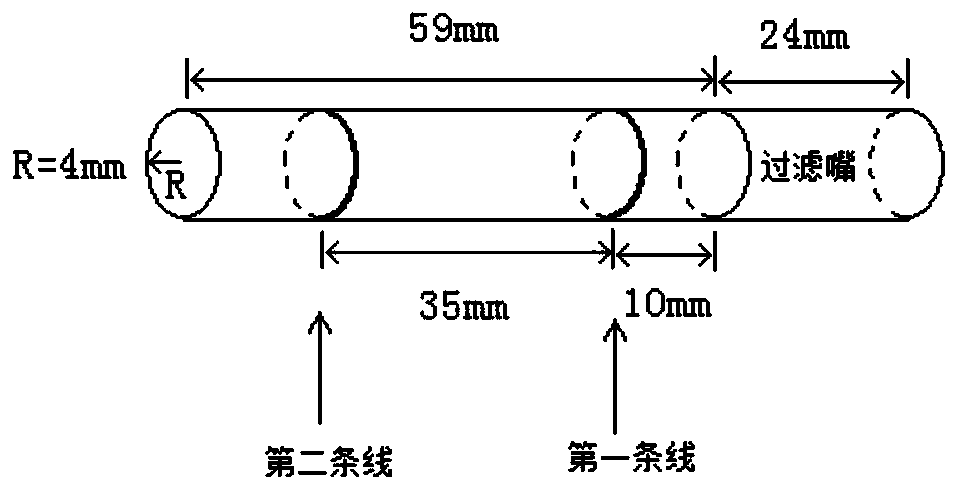

[0061] 4. Calculation method for the mass of shredd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com