Method for manufacturing air purifier

An air purifier and manufacturing method technology, applied to chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of inconvenient replacement, incomplete filtration, high manufacturing cost, etc., and achieve the effect of simple manufacture and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

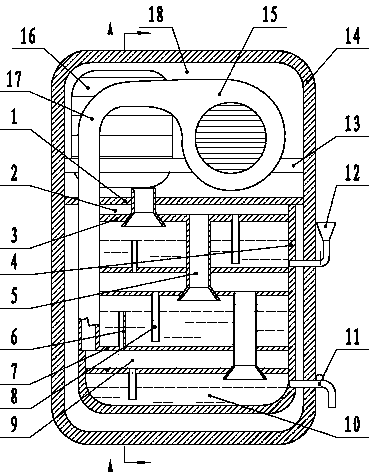

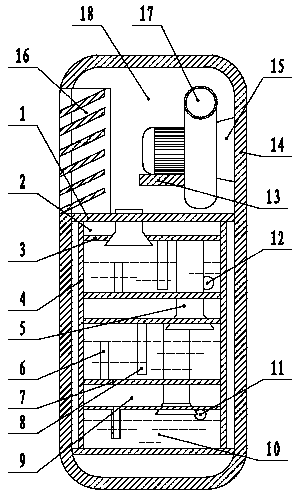

[0009] A large partition cover (1), small partition (3), water level partition (7) and purification inner shell (4) of an indoor air purifier are installed to form the top air circulation layer (2) and water purification layer (10), the top air circulation layer (2) and the bottom air circulation layer (9), the air conveying trumpet pipe (5), and the air purification pipe (8) are the main pipes for air circulation, purifying the inner shell (4) Install the large compartment cover (1) to form a purification body, and the air delivery horn tube (5) passes through the small partition (3), the bottom air circulation layer (9), and the large compartment cover (1) in turn to enter the air circulation chamber ( 18) to make the air unblocked, the water level leakage pipe (6) is installed on the water level interlayer board (7) to control the height of the water level, the excess water flows downward through the water level leakage pipe (6), and there are countless air purification pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com