Adjustable drawing device for preventing arching of material strip in stamping die

A stamping die and equipment technology, applied in the field of adjustable pulling equipment, can solve the problems of unfavorable strip-shaped sheet material, upper arch in the middle, stamping, etc., and achieve the effects of improving stamping work efficiency, good use effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

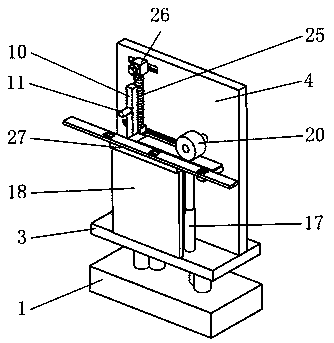

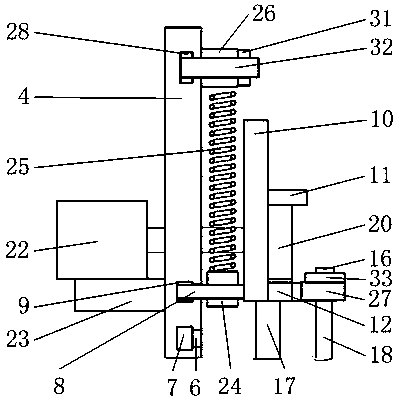

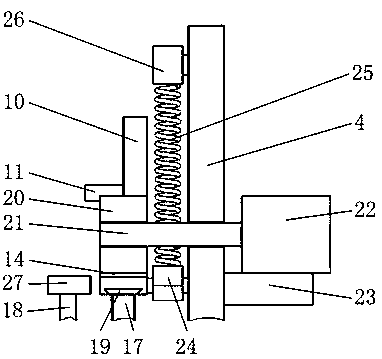

[0028] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0029] Such as figure 1 As shown, it includes base 1, electric push rod 2, lifting plate 3, support plate A4, guide pin 8, rack 10, transmission plate 12, tooth plate 14, block 16, telescopic rod 17, gear 20, electric drive Module 22, connection block A24, return spring 25, connection block B26, wherein as Figure 6 As shown, two electric push rods 2 are symmetrically installed on the upper end of the base 1, and a lifting plate 3 is installed on the upper ends of the two electric push rods 2; figure 1 , 4 As shown, the upper end of the lifting plate 3 is equipped with a support plate A4 and a telescopic rod 17 with a compression spring inside, and the compression spring is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com